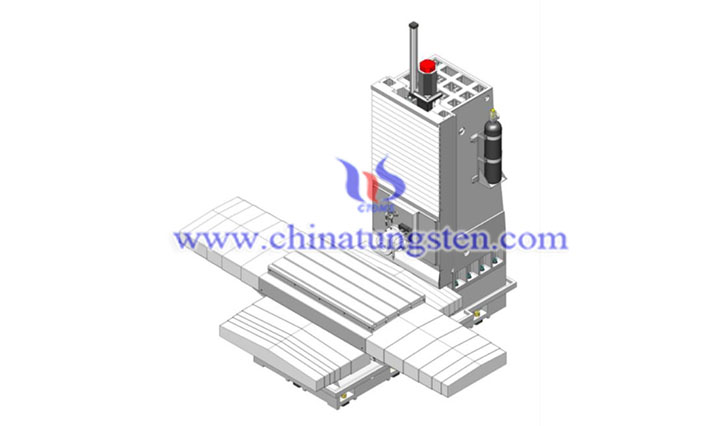

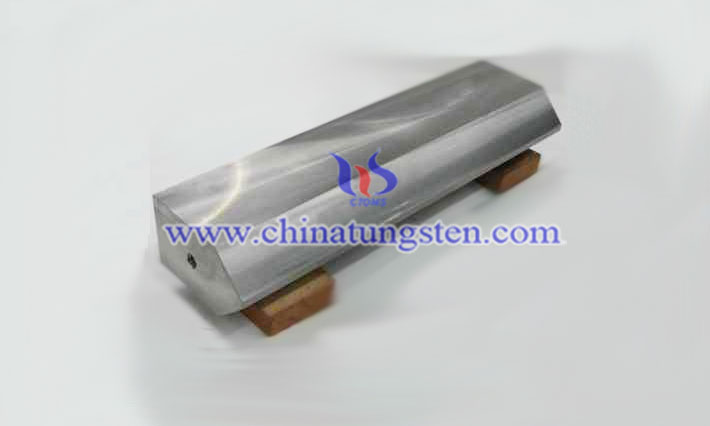

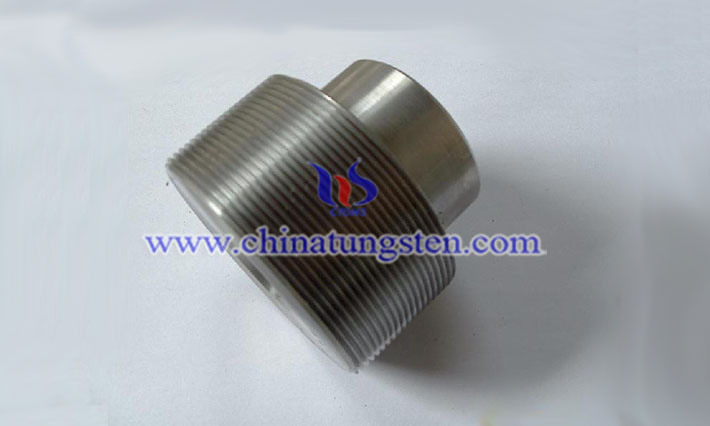

Tungsten Alloy Surface Milling Processing

- Details

- Category: Tungsten Information

- Published on Friday, 07 May 2021 11:30

Milling processing is divided into down milling and up milling. Down milling is a milling method in which the rotation direction of the contact part of the milling cutter and the workpiece is the same as the cutting feed direction. Up milling is a milling method in which the rotating direction of the contact part of the milling cutter and the workpiece is opposite to the cutting feed direction.

Tungsten alloy material is relatively hard, and both down milling and up milling are available, but up milling is more suitable.

The main differences between the two are different stress characteristics and different chip changes. The cutting edge of down milling is mainly subjected to compressive stress. The cutting edge of up milling is mainly subjected to tensile stress. The chip of down milling changes from thickness to thin, the cutting edge and the workpiece are mutually squeezed, and the relative sliding friction is small, which can reduce the tooth wear, surface hardening, and surface roughness. The chip of up milling changes from thin to thick, which is generated when the blade cuts in strong friction generates more heat than down milling and hardens the machined surface.

Up-milling and down-milling, because the cutting thickness when cutting into the workpiece is different, and the contact length between the tooth and the workpiece is different, so the degree of wear of the milling cutter is different. When down-milling, the durability of the milling cutter is 2 to 3 times higher than that of up-milling, and the surface is rough. The degree can also be reduced. But down milling is not suitable for milling hard-skinned workpieces. The power consumption of down milling is smaller than that of up milling. Under the same cutting conditions, the power consumption of down milling is 5% to 15% lower. At the same time, down milling is also more conducive to chip removal. Generally, down milling should be used as much as possible to improve the surface finish (reduce roughness) of the processed parts and ensure dimensional accuracy. However, when there is a hard layer, slag accumulation on the cutting surface, and significant unevenness on the surface of the workpiece, such as processing a forging blank, the up milling method should be used.

When down milling, the cutting thickness becomes thinner, and the cutter teeth cut into the unmachined surface, which is beneficial to the use of the milling cutter. In up-milling, when the cutter teeth of the milling cutter contact the workpiece, they cannot cut into the metal layer immediately, but slide a short distance on the surface of the workpiece. During the sliding process, due to strong friction, a large amount of heat will be generated, and at the same time, the surface to be machined. It is easy to form a hardened layer, which reduces the durability of the tool, affects the surface finish of the workpiece, and brings disadvantages to cutting. In addition, during up milling, since the cutter teeth cut from bottom to top (or from the inside to the outside) and cut in from the hard surface layer, the cutter teeth are subjected to a great impact load, and the milling cutter becomes dull faster, but the cutter teeth cut in. There is no slippage in the process, and the worktable will not move during cutting.

According to these differences, attention should be paid to the selection of milling cutters during milling processing of tungsten alloy surface. Use the correct tooth pitch of the milling cutter suitable for the process to ensure that there are not too many blades involved in the cutting, otherwise it will cause vibration. Use positive rake-angle indexable inserts as much as possible to ensure smooth cutting action and lowest power consumption. For narrow workpieces or when milling with gaps, ensure that there are enough blades to take the knife.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com