Preparation Method of Tungsten Disulfide Carbon Nanotube Negative Electrode Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 September 2020 16:30

Compared with the negative electrode made of tungsten disulfide alone, the tungsten disulfide carbon nanotube negative electrode material has better rate performance and cycle stability, and is more suitable for participating in the production of sodium ion batteries. What is the preparation method of tungsten disulfide carbon nanotube anode material?

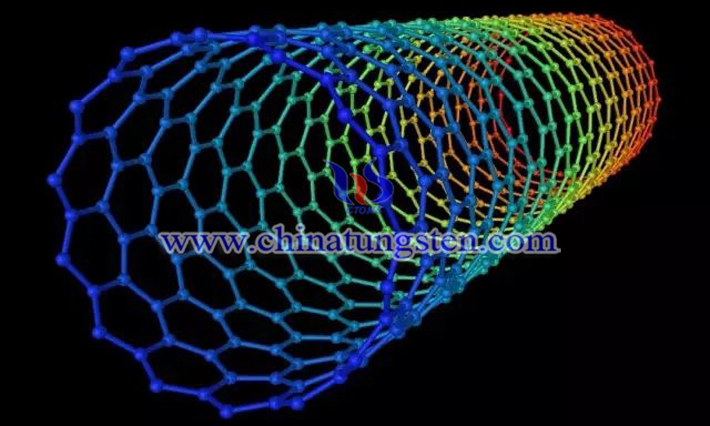

The tungsten disulfide semiconductor, which is similar to the layered structure of graphene, has attracted wide attention from scientists due to its distinctive physical and chemical properties and simple synthesis process. According to the researcher, although WS2 nanosheets have a high initial specific capacity as a negative electrode material for sodium-ion batteries, the rate performance of the prepared electrode materials is poor due to their low electronic or ion conductivity. In addition, WS2 will also produce serious volume expansion during the deintercalation of sodium ions, which greatly reduces its cycle stability as an electrode material. In this regard, the researchers combined tungsten disulfide and carbon nanotubes, and the composite material can be used as the negative electrode of chemical batteries.

A preparation method of tungsten disulfide carbon nanotube composite material includes the following steps:

(1) The tungsten source and the carbon nanotubes are respectively placed in the upwind and downwind zones of the dual temperature zone tube furnace for heating to obtain the tungsten oxide/carbon nanotube precursor. The upwind zone temperature is 800-1000°C, The temperature in the downwind zone is 50-150°C.

(2) The elemental sulfur, reducing agent and the compound obtained in step (1) above are fully stirred and then undergo a hydrothermal reaction. The hydrothermal reaction temperature is 180-250°C.

(3) The hydrothermal reaction product obtained in step (2) is calcined to remove sulfur to obtain a sodium ion battery tungsten disulfide carbon nanotube negative composite material in which tungsten disulfide nanosheets are uniformly coated on carbon nanotubes.

Compared with the traditional production process, the preparation method has relatively simple process, lower raw material cost, better repeatability, stronger operability, and is conducive to large-scale industrial production. The products produced have high charge-discharge specific capacity, features such as good rate performance and cycle stability.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com