Carburization of Ammonium Paratungstate (APT) by Methane

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2020 00:08

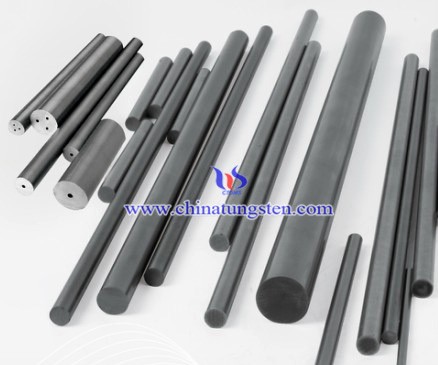

Fabrication of cemented carbides is the main use of tungsten carbide (WC). This application uses powders with a wide range of mean particle size. Submicron grained cemented carbides use very tiny tungsten carbide powders, which is very useful as catalyst. Cemented carbides of submicron carbide grains show an improved toughness to hardness ratio.

The conventional method to prepare WC is by carburization of tungsten powder with carbon black. The carburization occurs in fixed bed tubular reactors with flowing hydrogen, the temperatures inside could be over 1400 °C. Thus a method with lower temperature is needed.

Scientists has invented a low-temperature production method of WC from carburization of ammonium paratungstate (APT) under a flow of methane, the process is as follows:

APT. hydrogen (99.9995%) and CH4 (99.99%) were applied as precursor materials. Argon (99.997%) was used as purge gas. The APT powder was dry milled and passed to a sieve of aperture #400. This fraction was applied for carburization. The as supplied APT was also applied to investigate the effect of the APT particle size on the reaction time. The original powder has faceted particles. The fragments of the original particles make up milled powder.

In conclusion, WC was obtained from the carburization of APT in temperatures as low as 800 °C by a mixture of methane and hydrogen to yield. Even so, the reaction time relies on parameters such as gas flow, powder charge, gas composition, reaction temperature and fineness of the powder. By increasing temperature, gas flow, amount of methane in the mixture and powder fineness and decreasing the powder charge can improve the overall reaction rate (reduction and carburization).Parameters such as gas flow, fineness of the powder and powder charge anticipate the starting of carburization by rising the reduction rate.

The availability of carbon at the surface of the tungsten particles can affect the carburization rate to a large extent. Gas flow and the composition of the gas mixture might influence it. The rise of the powder charge (width of the powder layer) reduces both reduction and carburization rates, because it makes the diffusion of the gases more difficult.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com