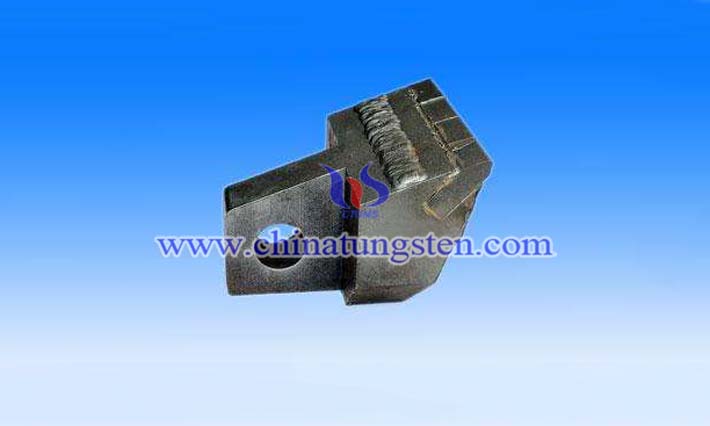

Tungsten Carbide Cutter Applied for Tunnel Boring Machine

- Details

- Category: Tungsten Information

- Published on Thursday, 07 May 2020 09:02

A cutter applied for a tunnel boring machine (TBM) is mainly tungsten carbide cutter as tungsten carbide has unique properties, such as good wear resistance, high hardness, high compressive strength, high elastic modulus, strong impact resistance, high corrosion resistance, and dimensional stability. Tungsten carbide cutters applied for a TBM have different types including tungsten carbide hobs, tungsten carbide scrapers, tungsten carbide tooth cutters, and so on.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-blade-bar.html

According to the researchers, not only the cutter layout and cutter shape will affect the cutting effect, excavation status and progress of the TBM, but the materials used by the cutter will also have a certain impact on the above situation. Therefore, while designing the cutter’s layout and shape of a TBM, the researchers also paid great attention to the choice of cutter materials. It has been reported that a tunnel boring machine is two to four times faster than the drill and blast method. And under normal circumstances, the shield cutter is mainly made of coarse-grained tungsten carbide-cobalt cemented carbide.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com