Tungsten Oxide Nanowires Preparation by Low Temperature Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 October 2019 22:43

Tungsten oxide is a typical transition metal oxide with a band gap of 2.4-2.8ev, which belongs to a typical n-type semiconductor. In addition to catalysis, electrochromism, battery electrode, solar energy absorbing material and invisible material, tungsten oxide also has the properties of semiconductor functional materials such as pressure sensitive, thermal sensitive and gas sensitive.

The traditional preparation process of tungsten oxide nanowires is complex, energy consumption is large, and the experimental conditions of these methods are demanding. Some hydrothermal temperature is as high as 200 ℃, and the hydrothermal time is as long as 24 hours or even longer. In the traditional hydrothermal process, the reaction vessels used are all high-pressure reaction kettles lined with polytetrafluoroethylene. This kind of equipment consumes a lot of energy.

In order to solve the above problems, some scholars have developed a process for preparing tungsten oxide nanowires at low temperature. The preparation steps are as follows:

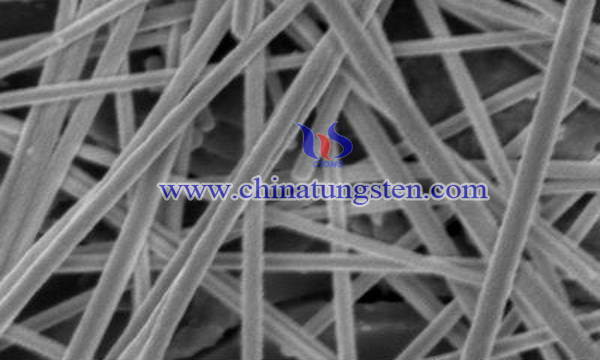

Prepare 50ml of 0.01mol/l Na2WO4 · 2H2O aqueous solution, choose (NH4)2SO4 as surfactant, and add 0.66g in the solution; under the condition of magnetic stirring, add concentrated hydrochloric acid into Na2WO4 · 2H2O solution drop by drop at the speed of 0.1ml/s, and stop adding when the pH value of the solution is adjusted to 5; transfer the mixed solution to a sealed glass bottle, and when the drying box temperature is stable at 95 ℃, transfer the glass solution. The glass bottle was placed in a constant temperature drying oven and reacted for 3h; the precipitates obtained after the reaction were washed twice with water and ethanol respectively, and dried for 1H at 60 ℃ in an oven. The tungsten oxide obtained was nanowire structure with a diameter of about 10nm and a length of 200-300nm.

Compared with the existing preparation methods of tungsten oxide nanowires, the low temperature hydrothermal method is simple in process, simple in operation, ultra-low in reaction temperature, and can greatly shorten the reaction cycle, simple in equipment requirements, just using ordinary glass containers, and lower in energy consumption and cost compared with the traditional method of PTFE lined high-pressure reactor.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com