Tungsten Oxide - Vanadium Oxide Heterojunction Nanowires Preparation by Gas Phase Method

- Details

- Category: Tungsten Information

- Published on Thursday, 24 October 2019 23:08

In the 21st century, the level of industrialization is developing rapidly, but the natural environment and ecology on which human beings depend for survival are seriously damaged, and there are a lot of poisonous and harmful gases in the air. Therefore, it is urgent to make a highly efficient and accurate detector to detect and prevent toxic and harmful gases.

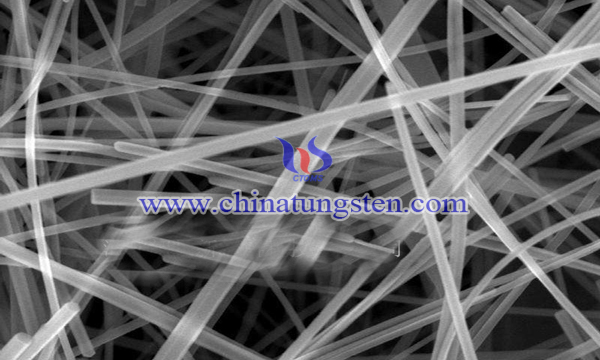

In order to obtain a gas sensitive detector with high selectivity, high sensitivity, low working temperature and high stability, gas sensitive properties are mainly improved by modifying gas sensitive materials. Tungsten oxide with one-dimensional nanowire structure attracts many researchers because of its huge specific surface area. In the aspect of gas sensing material modification, the main ways are doping noble metal Pt, Au, PD or transition metal oxide, in addition, it can be modified by constructing heterostructure. Compared with the two, the cost of heterostructure modification is relatively low. Some scholars have proposed a tungsten oxide vanadium oxide heterojunction nanowire array, which is prepared according to the following steps:

Step 1: deposit tungsten thin film material layer on the substrate by magnetron sputtering, using metal tungsten as target, using inert gas as sputtering gas, sputtering working pressure is 1-2.0pa, sputtering power is 80-110w, sputtering time is 15-20min;

Step 2, tungsten oxide nanowires were grown by crystallization of the tungsten films prepared in step 1 in a vacuum high-temperature tubular furnace. The ambient atmosphere was a mixture of oxygen and argon. During the growth of tungsten oxide nanowires, the flow rates of oxygen and argon were controlled to 0.1 SCCM and 35-50 SCCM, respectively. The growth pressure in the furnace was controlled to 140-160pa. The temperature of the tubular furnace was raised from 20-25 ℃ to 600-700 ℃, and the temperature was increased to 600-700 ℃. The temperature rate is 5 ℃ / min, the temperature is kept at 600-700 ℃ for 1-2 hours, then the temperature is lowered for 1 hour to 300-400 ℃, finally the temperature is naturally cooled to 20-25 ℃.

Step 3, annealing of the tungsten oxide nanowires, annealing the tungsten oxide nanowires prepared in step 2 at 300-500 ℃ and air atmosphere for 1-2 hours to further stabilize the crystal orientation;

Step 4, a vanadium film was deposited on the tungsten oxide nanowire layer of the substrate treated in step 3 by magnetron sputtering. Metal vanadium was used as the target and inert gas as the sputtering gas. The flow rate of inert gas was 30-50sccm, the working pressure of sputtering was 2.0pa, the sputtering power was 80-110w, and the sputtering time was 2-5min.

Step 5, annealing and heat treatment of vanadium, annealing the substrate of the deposited metal vanadium film at 300-500 ℃ and air atmosphere for 1-2 hours;

Compared with the prior art, the one-dimensional tungsten oxide vanadium oxide heterojunction nanowires are prepared by the gas phase method. Compared with the existing methods of thermal evaporation and electrodeposition, the nanowires have the advantages of simple equipment, convenient operation, easy control of process parameters and low cost. Moreover, the structure is a one-dimensional nanowire array with high specific surface area, which can give full play to the advantages of heterojunction. There is a great research space for the application of this material in reducing the working temperature of gas sensor, improving the sensitivity and response speed of the sensor.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com