Iron Doped Tungsten Trioxide Photocatalyst Preparation by Electrochemical Deposition

- Details

- Category: Tungsten Information

- Published on Thursday, 24 October 2019 22:46

In 1972, Honda and Fujishima successfully used n-TiO2 electrode to produce hydrogen from water by photolysis of solar energy, which made people realize the application prospect of Photoelectrochemical conversion of solar energy to electric energy and chemical energy. At the same time, this technology is applied to solve the problem of dye wastewater and other industrial wastewater.

Iron is uniformly dispersed on WO3 thin film electrode by impregnation with iron nitrate as raw material, which is simple and cheap. Fe2O3 is formed by Fe doping, and Fe3+ can capture photogenerated electrons, thus inhibiting the recombination of photogenerated electrons and holes, so as to improve the photoelectric conversion efficiency and photocatalysis ability.

The method for preparing iron doped tungsten trioxide photocatalyst by electrochemical deposition includes the following steps:

1)preparation of amorphous tungsten oxide film: dissolve 0.0025-0.0100mol of Na2WO4 in 50ml of distilled water, add 0.25-1.00ml of H2O2 solution with mass percentage concentration of 30%, add 30ml of isopropanol, stir for 1 minute to obtain w2o72 solution, then adjust the pH value of w2o72 solution with 2mol / L of perchloric acid or nitric acid to 1.10-1.40, add distilled water to w2o72 solution to 100ml of volume to obtain clarification. Taking ITO conductive glass as the working electrode, platinum electrode as the counter electrode and saturated calomel electrode as the reference electrode, the electrode was electrodeposited in the electrolyte, the cathodic potential relative to calomel electrode was - 0.4-0.6v, the deposition time was 60 minutes, the amorphous tungsten oxide film was obtained and dried for standby.

2)impregnation doping of iron: put the amorphous tungsten oxide film obtained in step 1) into 0.005mol/l Fe(NO3)3 solution for 20-40 minutes to obtain the iron doped tungsten oxide film, take it out, wash it with distilled water, and dry it in air;

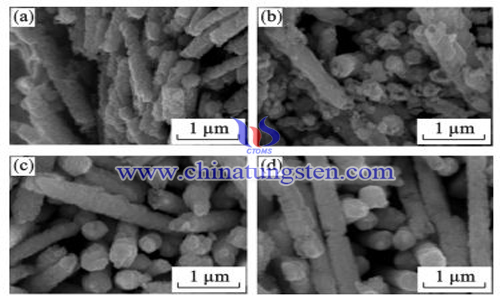

3)calcination: put the iron doped tungsten oxide film obtained in step 2) in muffle furnace, calcine it at high temperature at 450 °C for 3 hours, cool it to room temperature and take it out to obtain the iron doped tungsten oxide photocatalyst.

The experimental equipment is simple, the deposition rate is fast, the operation is convenient, the energy consumption is low, and the reproducibility is high. The optical absorption band of the finished product is wider than that of the pure tungsten trioxide, and its photoelectric performance is significantly improved.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com