Spherical Tungsten Powder Preparation by Radio Frequency Plasma

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 June 2019 21:42

Spherical tungsten powder is mainly used in thermal spraying, filter materials, cathode and porous materials because of its good sphericity and fluidity and high compacting density. At present, the demand for high quality spherical tungsten powder is increasing day by day. In the field of thermal spraying, spherical tungsten powder is more uniform and compact because of its good fluidity and high compacting density.

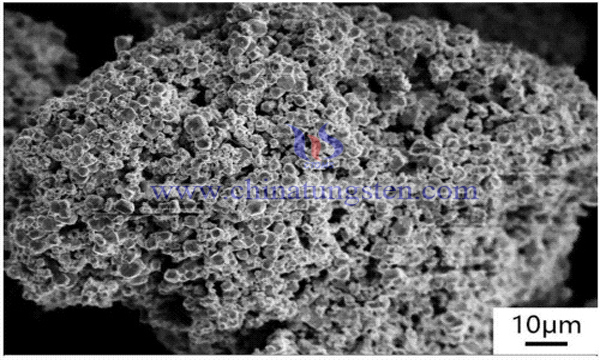

At present, tungsten trioxide is usually prepared by drying and calcining pure tungstic acid or ammonium paratungstate (APT) in industry, and then reduced in hydrogen to prepare tungsten powder. The tungsten powder prepared by this method is very regular polycrystalline, and the particle size of the powder is mostly controlled at 2-5 um. The spherical tungsten powder prepared by radio frequency plasma has the advantages of homogeneous composition, few defects, good sphericity, lower production cost and higher production efficiency. It is a good way to prepare ultra-coarse spherical tungsten powder. Ultra-coarse spherical tungsten powder was prepared by radio frequency plasma technology with conventional tungsten powder as raw material. It has good fluidity, high sphericity and low oxygen content. The details of the preparation method are as follows:

1.Using conventional tungsten powder as raw material, precursor powder was obtained by granulating with 5wt.% polyvinyl alcohol (PVA) solution, and adding 4wt.%, vacuum drying for 1H at 60 ℃ after granulation and sieving.

2.Before RF plasma arcing, the vacuum is pre-pumped to 1.0*Pa by diffusion pump unit to prevent tungsten from reacting with oxygen to form tungsten oxide. The main parameters of RF plasma are as follows: argon as working gas, side gas and carrier gas, working gas flow rate 35slpm, side gas flow rate 120slpm, system negative pressure 240mm mercury column, carrier gas flow rate 5slpm, powder feeding rate 30g/min, equipment output power 60KW. After the precursor powder is fed into the high temperature region of plasma, the precursor powder is endothermally melted and spheroidized and solidified into spherical powder by quenching.

The preparation of spherical tungsten powder by radio frequency plasma has the characteristics of high temperature, large volume of plasma torch and high energy density. The precursor powder can melt rapidly and condense into spherical powder. It has fast heat transfer and cooling speed, no electrode pollution and controllable reaction atmosphere.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com