Spherical Tungsten Carbide Synthesis by Template Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 16:05

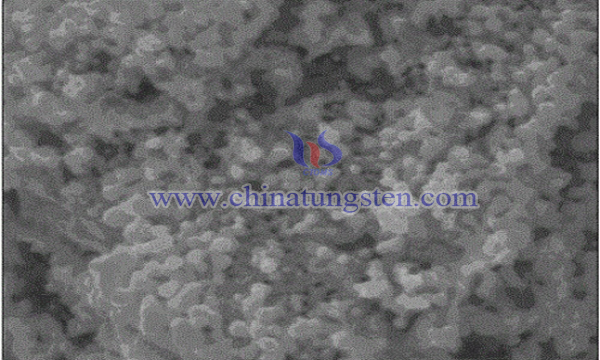

Spherical tungsten carbide powder has high hardness, high wear resistance, acid and alkali resistance, high chemical stability. It has wide potential application value in fuel cell anode, cathode catalyst material, gas sensor, petroleum catalyst and photocatalyst material.

The existing preparation methods of tungsten carbide powder are directly burning tungsten powder and carbon black at high temperature, resulting in irregular shape of tungsten carbide powder, which can not meet the requirements of special fields. At present, the market demand for high quality spherical tungsten powder is increasing day by day. How to prepare spherical tungsten carbide more efficiently has become an urgent need of the industry.

The preparation methods of spherical tungsten carbide powders are various. The domestic preparation methods mainly focus on the improvement of traditional production technology. As far as possible, the cast tungsten carbide powders with regular shape and fine structure can be obtained. Recently, spherical tungsten carbide powders have been prepared by the model method. The main mechanism is that glucose solution is used as carbon source model, soluble tungsten salt is used as tungsten source in spherical skeleton. Under certain technical conditions and molar ratio conditions, spherical tungsten carbide powders with high hardness, high wear resistance, acid and alkali resistance and high chemical stability are prepared. The specific operation is as follows:

Soluble tungsten source (AMT) with a molar ratio of 1:30 and glucose aqueous solution with a mass concentration of 7% were reacted in a high-pressure autoclave at 200 ℃ for 24 hours, filtered and air-dried at 90 ℃, then burned in a fourteen-tube hydrogenation furnace at 900 ℃ for 9 hours to prepare reductive prepolymer, and then burned in a molybdenum wire furnace at 1200 ℃ for 3-5 hours to obtain spherical tungsten carbide powder.

The results show that the spherical tungsten carbide powder synthesized by this method is simple and easy to industrialize. The obtained spherical tungsten carbide has the advantages of high purity (tungsten carbide content is greater than 90%, WC2 content is less than 1%, free carbon is less than 2%), high hardness, high wear resistance, acid and alkali resistance, and high chemical stability.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com