Spherical Mesoporous Silica Supported Phosphotungstic Acid Composite Catalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 05 May 2019 21:26

Sulfuric acid and hydrochloric acid are commonly used as catalysts for the synthesis of ethyl acetate. In addition to traditional inorganic acids, there are solid superacids and ionic liquids supported on mesoporous materials. The inorganic acid catalyst corrodes the instrument seriously, and the homogeneous catalytic products are not easy to separate, which is easy to produce waste acid waste liquid and other pollutants. Solid acid also has the disadvantage of serious corrosion to the instrument, and the catalytic activity decreases quickly and the cost is high.

If mesoporous materials are used as supports to support homogeneous catalysts, instrumental corrosion can be avoided. Catalysts are easy to separate catalysts from products and can be recycled repeatedly. But at present, the commonly used loading methods are solvent-supported catalysts. In the process of treating catalysts, the added solvents must be removed. The process is complex and the cost is increased.

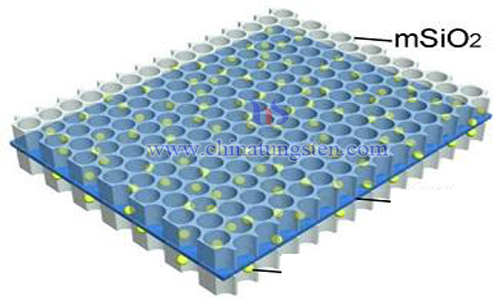

In order to overcome the shortcomings of existing catalysts for catalytic synthesis of ethyl acetate, such as serious corrosion to equipment and complex process, researchers used phosphotungstic acid. A spherical mesoporous silica supported phosphotungstic acid composite catalyst was prepared by using spherical mesoporous silica as support. The preparation process of the catalyst is as follows:

1.Triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (abbreviated as P123) and glycerol were added into hydrochloric acid and mixed into solid substance to dissolve sufficiently.

2.Adding tetraethyl orthosilicate to the solution obtained in the previous step, stirring at 25-60 ℃ for 1-10 minutes at a mechanical stirring rate of 300-500 r/min, then standing for 5-100 hours.

3. The solution obtained from the previous step is placed in a sealed reaction vessel and crystallized at 90-180 degrees ℃ for 10-40 hours.

4. The crystallized products are filtered, the filtered solids are washed and dried with deionized water to obtain the raw powder of spherical mesoporous materials.

5. The spherical mesoporous silica was obtained by calcining the raw powder of the spherical mesoporous material at 300-600 ℃ for 8-24 hours and removing the model agent.

6. The spherical mesoporous silica and phosphotungstic acid were added to the ball mill pot of the ball mill. The ball mill pot was grinded continuously for 0.1-100 hours at a speed of 300-500 r/min and a temperature of 15-100 ℃. Then the solid powder was extracted, i.e. the spherical mesoporous silica loaded with phosphotungstic acid was obtained.

The spherical mesoporous silica supported phosphotungstic acid composite catalyst has good catalytic performance. When it is used to catalyze esterification of acetic acid and ethanol, there are few side reactions and no corrosion to the equipment. Moreover, the supported catalyst can be recycled and reused, and the post-treatment process is simple.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com