Tungsten Carbide--Carbon Nanotube Composites

- Details

- Category: Tungsten Information

- Published on Saturday, 27 April 2019 22:05

Although tungsten carbide has platinum-like catalytic performance and strong anti-CO poisoning ability, its dispersibility is poor, its specific surface area is small, it is easy to agglomerate, and its conductivity is poor, and its catalytic activity is not ideal. Compared with platinum and other noble metal catalysts, there is still a big gap.

Scholars believe that composite materials are one of the effective ways to improve the catalytic activity of tungsten carbide. The catalyst carrier is also an important factor affecting the catalytic activity of the catalyst. For example, carbon nanotubes (CNTs) are commonly used as carrier materials in DMFC. Carbon nanotubes have excellent electronic properties, nano-tube structure, large specific surface area and graphite-like multi-layer tube wall. As carriers, carbon nanotubes can improve the dispersion of active components and enhance the conductivity of materials. WC-CNTs prepared by composite tungsten carbide nanoparticles onto carbon nanotubes showed that the electrocatalytic performance of WC-CNTs composite for methanol was significantly stronger than that of pure tungsten carbide.

The preparation method of a tungsten carbide-carbon nanotube composite with three-dimensional network structure is as follows:

(1)Tungsten source is dissolved in solvent in microwave tube, stirred uniformly, microwave tube is placed in microwave synthesizer and reacted at 160 for 60 minutes. After reaction, the reaction product is cooled to room temperature. After centrifugal washing with deionized water and anhydrous ethanol, it is dried in a vacuum oven at 50 for 6 hours to obtain W18O49 with oxygen defect. The tungsten source is WCl6, and the solvent is anhydrous ethanol. The volume of solvent is 100 mL/g by tungsten source quality meter, and the pressure of microwave reaction is 15 bar.

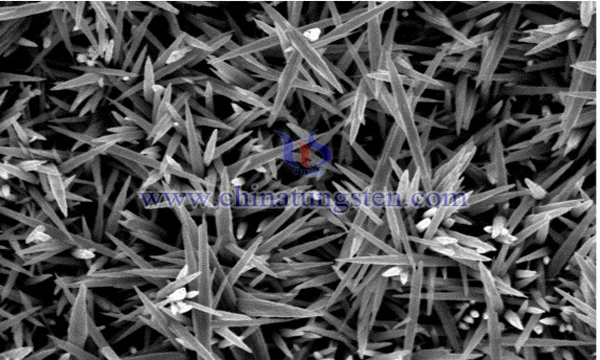

(2)The W18O49 obtained by step (1) is placed in a tubular furnace, carbonized at 900 ℃ for 180 minutes, then cooled to room temperature in a nitrogen-protected atmosphere to obtain tungsten carbide-carbon nanotube particles. When the carbon source is acetylene, the mixture of acetylene, hydrogen and argon is used, the acetylene: argon gas volume ratio is 30:30:40, and the flow rate of the mixture is 100 mL/min.

Tungsten oxide with oxygen defect is used as precursor to promote atom diffusion, which is conducive to the carburization process. Carbon nanotubes (CNTs) are grown in situ on tungsten matrix to prepare tungsten carbide-CNTs composites with controllable morphology. This three-dimensional network structure can effectively disperse WC particles and ensure that WC and Pt have more contact surfaces. Such a structure can also make carbon nanotubes contact WC and Pt at the same time, improve the conductivity of the composites as a whole, play a better role of the three, and improve the electrocatalytic effect.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com