Zinc Modified Tungsten Trioxide Thin Film Photoelectrode

- Details

- Category: Tungsten Information

- Published on Thursday, 28 February 2019 22:31

It has been found that modification is the most effective way to improve the photocatalytic activity of tungsten trioxide. Common modification materials are gold, silver, platinum, iron, copper, zinc, bismuth, titanium and so on. A kind of zinc modified tungsten trioxide thin film photocathode material is introduced in this paper.

Zinc is also a kind of semiconductor material. The combination of zinc and zinc can effectively separate the electrons and holes by the transfer of electrons or holes using the energy band structure between the two semiconductors. The method is to use zinc (NO3)2 as raw material, uniformly disperse zinc ions on tungsten oxide thin films by deposition method, after heat treatment, and finally obtain zinc oxide/WO3 composite thin film photoelectrode material. The specific process includes:

1)Dissolve Na2WO4 in distilled water of 50 mL, add 0.25-1.00 mL mass percentage concentration of 30% H2O2 solution, stir for 3-5 minutes, get solution containing W2O72, add 30 mL ethylene glycol, stir for 1-3 minutes, get mixed solution, adjust PH value to 1.10-1.30 with 2 mol/L perchloric acid or nitric acid, add distilled water to make the volume of mixed solution reach 100 mL, and get clarified electrolyte with ITO. Conductive glass is the working electrode, platinum plate electrode is the electrode, and saturated calomel electrode is the reference electrode. The cathodic potential is 0.4V~0.6V relative to saturated calomel electrode, and the deposition time is 60 minutes. The amorphous tungsten oxide film can be dried out for reserve.

2)The amorphous tungsten oxide film was immersed in 0.005 mol/L zinc (NO3)2 solution for 20-40 minutes, washed with distilled water for 1-2 minutes, and dried in air to obtain zinc-modified tungsten trioxide film.

3)Zinc-modified tungsten oxide thin film was placed in muffle furnace, heat-treated at 450o ℃ for 3 hours, and cooled to obtain zinc-modified tungsten oxide thin film photocathode.

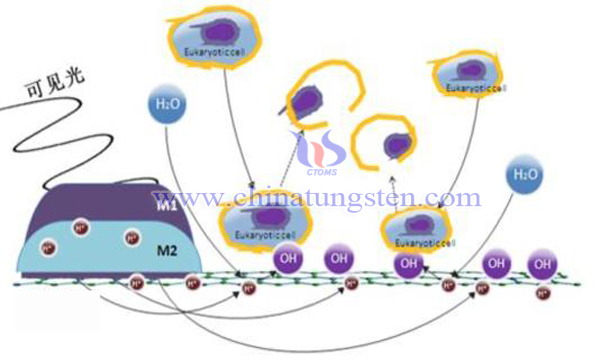

Zinc modified tungsten trioxide formed a layer of zinc oxide film on the surface of WO3. Because the valence band position of zinc oxide is more negative than that of WO3, photogenerated holes in the valence band of WO3 will flow into the valence band of ZnO under the action of electric field force when illumination reaches the film electrode, thus restraining the recombination of photogenerated electrons and holes in WO3, and achieving the purpose of improving photoelectric conversion efficiency and photocatalytic ability.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com