Polythiophene / Tungsten Oxide Composites Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 February 2019 20:52

Electrochromic phenomena refer to the reversible change of material color under external electric field. In recent years, more and more attention has been paid to electrochromic materials because of their great application prospects in stealth materials, smart chromic films and other fields.

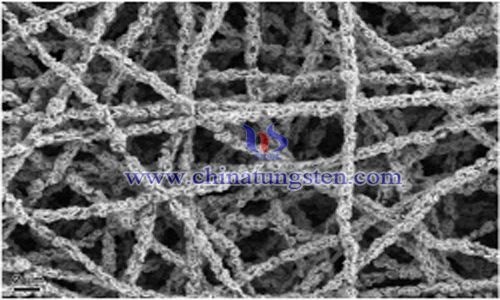

Poly (3,4-ethylenedioxythiophene) is a common conductive polymer. It belongs to cathodic coloring material as well as tungsten oxide in fast response. The reflection wavelength of visible light and tungsten oxide in the colored state are similar. The combination of the two can not only greatly shorten the response time, but also greatly improve the contrast. Unique tungsten oxide nanorods with anisotropic crystal structure and shape and polythiophene with porous structure increase the active specific surface area of the sample, accelerate electron transport, and significantly enhance the kinetic process of chromotropic reaction, thereby improving the electrochromic performance of the material. The preparation process of polythiophene/tungsten oxide composite is as follows:

(1)The FTO conductive glass was placed in a beaker with acetone, ethanol and deionized water for 10 minutes, respectively, and then dried by infrared lamp on the filter paper.

(2)Preparing peroxytungstic acid solution: 1.25g tungstic acid is dissolved in 30 mL deionized water by heating and stirring, then 10 mL of 30% hydrogen peroxide is added to it, stirred to the solution to clarify, and then diluted with deionized water to the tungsten concentration of 0.05 mol/L. The diluted solution is peroxytungstic acid solution.

(3)Preparing precursor solution: 11 mL tungstate peroxide, 44 mL acetonitrile and 11 mL deionized water were prepared as mixed solution by step (2). Then the pH of mixed solution was adjusted to 1 with 6 mol/L hydrochloric acid to prepare precursor solution.

(4)The prepared precursor solution was added to the autoclave, and FTO conductive glass was immersed vertically in the precursor solution. The autoclave was heated to 180 C for 12 hours, and the heating rate of the autoclave was 8 C/min.

(5)The treated FTO conductive glass was used as working electrode, platinum wire as opposite electrode, Ag/AgCl electrode as reference electrode, lithium perchlorate and 3,4-ethylenedioxythiophene monomer were dissolved in propylene carbonate solution as polymerizing electrolyte. The working electrode was immersed in the polymerizing electrolyte for 8 hours, ultrasonic for 20 minutes, then treated with 0.6V voltage for 30 seconds. Finally, the working electrode was immersed in constant current. Among them, the concentration of lithium perchlorate is 0.2 mol/L, the concentration of 3,4-ethylenedioxythiophene monomer is 0.1 mol/L, the current of constant current deposition is 2.5 ma/cm2, and the deposition time is 10 s.

(6)The product was rinsed with ethanol and deionized water, then dried on filter paper with infrared lamp. A dense and uniform transparent film, polythiophene/tungsten trioxide nanorod electrochromic material, was obtained on FTO conductive glass.

After synthesis, the organic/inorganic interface of tungsten oxide and polythiophene can be effectively hybrid and play a complementary role. Two cathodic coloring materials with similar coloring states can enter both coloring and fading states, which greatly improves the response speed and cycle stability of electrochromic materials.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com