New Research Progress - China's Newly Developed Laser Reflective Film Module Won the Third Time

- Details

- Category: Tungsten Information

- Published on Thursday, 08 November 2018 09:24

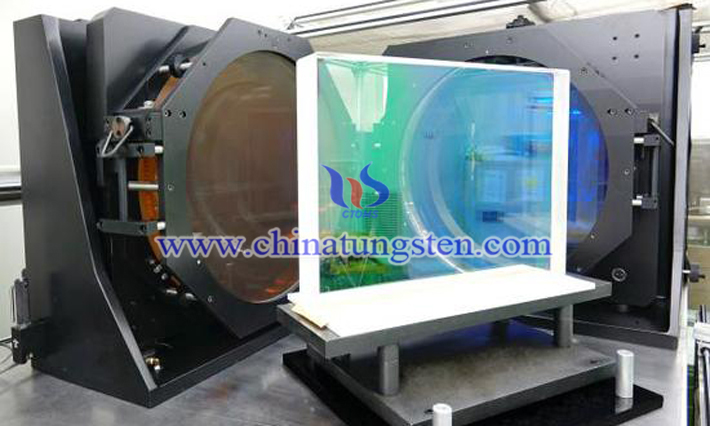

You are concerned about the news that "the Chinese have broken through the Western blockade of China and won the championship for the third time". Things are like this. Recently, the thin film optical laboratory of the Key Laboratory of Laser Materials of the Chinese Academy of Sciences, affiliated to the Shanghai Institute of Optics and Fine Mechanics (Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences) successfully developed a laser reflective film module, and for the third time won the fundamental frequency laser reflection. The International Competition for Laser Damage Thresholds for Thin Film Modules, the first time to win and the second to win in 2012 and 2013. They gradually seized and maintained the number one in the world, realizing the leapfrog development of China's high-power laser thin film technology. As for the middle blank period (2014~2017), Shanghai Optics Machinery Co., Ltd. did not participate in this international competition at the request of the relevant state departments.

Three competitions and three championships. This is a journey – from the first participation in the international competition to the leading international counterparts – compared to the second place, the damage threshold of the laser reflective film module developed in China is 20% higher! According to the relevant person in charge, this is a team that belongs entirely to our own country. The person in charge said that the "not bad" laser film is a determined and persistent pursuit of the "spider" and "shield" of laser damage and anti-laser.

So, do you know what this laser reflective film assembly is? This laser reflective film module is one of the core components of high-power laser devices, and is used in laser inertial confinement fusion research and in the field of aerospace and other lasers. Why does the West block this technology against China? The reason why Western countries impose strict technical blockade and product embargo on this aspect of China is because the preparation of high-power laser film is a long and complicated system engineering process, which requires multi-disciplinary application and is difficult to prepare. Therefore, the Chinese won the championship, and it is also invisible to pass on a message - China's technological development in the field of strong lasers will not be "card necked" by Western countries.

In addition to the core components such as laser reflective film components, high-power laser devices have numerous components. Among them, heat dissipation and package-related components, such as tungsten-copper heat sinks, can also affect laser performance. Therefore, it is necessary to first talk about the package form of the currently used high power laser - macro channel cooling form and micro channel cooling form.

The commonly used macro channel cooling method is to simultaneously solder a plurality of chips and a plurality of conductive and heat-conducting tungsten-copper transition heat sinks, and then integrally solder them on the insulating and thermally conductive base, or simultaneously use a single laser chip, a conductive heat conduction heat sink and an insulating heat conductive sheet. Welding, making a laser light-emitting unit, bonding a qualified laser unit to the base, and finally fixing the electrode to complete the preparation of the high-power laser.

In the process of the commonly used microchannel cooling form, the chip, the insulating sheet, the negative electrode and the microchannel tungsten copper heat sink are packaged into one micro channel unit, and then the plurality of micro channel units constitute a high power laser module. Among them, a tungsten-copper transition heat sink assembly capable of conducting and conducting heat is very important.

Seeing this, you may know what the chips, insulating sheets, and negative electrodes involved are, but you don't know what the heat sink is.

Industrially, heat sink refers to a material whose temperature does not change with the change in the amount of heat transferred to it. Generally speaking, it is a micro heat sink that is used to cool the chip. Then, what is the tungsten copper heat sink? Tungsten copper heat sink is a heat sink made of tungsten copper composite material.

The tungsten-copper heat sink material is a composite material of tungsten and copper, which has both low expansion characteristics of tungsten and high thermal conductivity of copper. That is to say, the thermal expansion coefficient and thermal conductivity of the tungsten copper heat sink can be designed by adjusting the composition of the material to form a good thermal expansion match with the semiconductor material, and is applied to a semiconductor high-power package. Of course, the tungsten-copper composite material can also be well-matched with ceramic materials and metal materials to form a good thermal expansion, and thus applied to industries such as optical communication.

You see, it is hard to imagine how much knowledge a technology goes into. In fact, it is enough to understand a material to drink a pot. What is more, technology is still developing at a critical point (which is so possible). easily). These are the dedication of researchers, who have made many advances in China's science and technology. Therefore, we should pay more attention to the scientific research personnel who have been difficult to overcome for decades, rather than some "big stars" who earn a lot of money but still evade taxes and tax evasion. Researchers should be the ones who really care! For example, China's famous physicist, material scientist, and dean of the Chinese Academy of Sciences, Yan Naiben.

Perhaps many of us don't know about this great man, but his outstanding contribution has benefited thousands of people, and in exchange for the rapid advancement of Chinese technology, it marks the self-improvement of Chinese technology and is widely recognized by the international community. The author admires such a pillar of the country - rejecting the "Olive Branch" of the United States and resolutely returning to China to invest in scientific research. Although the "Chinese backbone" has left us, the spirit and success that he left will be as long as the "Yu Nai Ben" is shining, guiding us forward.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com