Monolayer Layer Tungsten Disulfide Low-cost Preparation Method

- Details

- Category: Tungsten Information

- Published on Monday, 05 November 2018 22:56

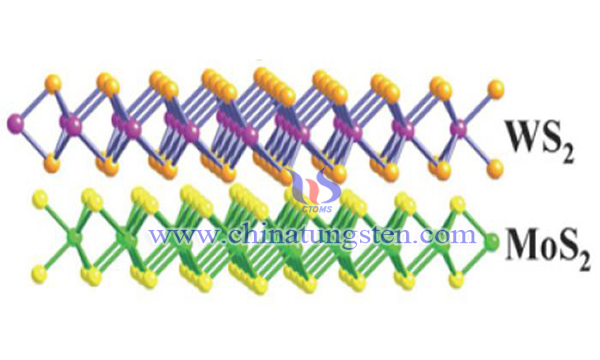

Tungsten disulfide and molybdenum disulfide are typical sandwich layered structures. Because of their relatively weak van der Waals force between layers, tungsten disulfide can also be peeled into single or few layers of nanosheets. It is considered to be another important two-dimensional nanosheet material with unique physical, chemical and electrical properties. However, it is difficult to prepare pure tungsten sulfide nanomaterials with single layer structure in general chemical and physical methods.

In order to solve the technical problems existing in the preparation of monolayer tungsten disulfide, some researchers have proposed a simple, safe, efficient and suitable method for large-scale production of monolayer tungsten disulfide nanosheets. This method directly uses ammonium thiotungstate as raw material, and after heat treatment in the temperature range of 300 - 1200 ℃, the 2H phase monolayer tungsten disulfide nanosheets can be obtained by self-peeling in small molecular solvents such as ethanol and water. Its specific steps are:

(1)Ammonium thiotungstate was heated at 300-1200 ℃ for 1-10 h under inert gas protection, then cooled to room temperature to obtain 2H phase tungsten disulfide bulk to be peeled.

(2)The obtained tungsten disulfide block was placed in a centrifugal tube, and the suspension of tungsten disulfide nanosheets was obtained by ultrasonic peeling with small molecular solvent for 10-72 hours, then centrifugal separation and precipitation in a centrifuge.

(3)The obtained suspension of tungsten disulfide nanosheets was placed in a centrifugal tube for 1-10 hours, and then centrifuged in a centrifuge to separate precipitates. The suspension of 2H phase monolayer tungsten disulfide nanosheets with a thickness of less than 1 nm was obtained.

The new process has the advantages of simple operation, mild reaction conditions, low cost of reagents and environmental protection. The preparation of tungsten disulfide from ammonium thiotungstate raw materials can avoid the use of lithium salt reagents such as LiOH and Li2CO3, which are expensive in the existing technology, thus saving lithium resources and greatly reducing the preparation cost.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com