Nanometer Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 June 2018 21:48

In addition to the addition of rare earth elements, the physical and chemical properties of tungsten powder itself are also very important. The particle size of tungsten powder is micrometer. Because of the large size of the tungsten powder, the powder is small, the distribution of active components in the powder is uneven, the surface active layer is thinner, the active material has a poor migration and diffusion at high temperature, which leads to the tungsten. Electrode zero field emission current density is low, high temperature resistance is low, thermal reflection performance is poor, tungsten electrode burning rate is difficult to adapt to the requirements of modern finishing.

Therefore, the use of nano-tungsten powder instead of micro-tungsten powder has become the current mainstream thinking, some scholars in the study of nano-tungsten powder electrode manufacturing program summarized in the following six steps:

1.According to the mass percentage, 0.1% ~ 0.37% lanthanum nitrate, 2.33% ~ 5.6% yttrium nitrate, 0.35% to 1.05% cerium nitrate and 92.25% ~ 96.5% ammonium tungstate were obtained. Lanthanum nitrate, yttrium nitrate and cerium nitrate were dissolved in the distilled water to get mixed solution, and ammonium para tungstate was added to the dopant pot, and then mixed solution was added to the dopant pot. Heating and stirring until dry rare earth compound ammonium partrungstate powder.

2.Under the protection of hydrogen under high temperature reduction rare earth composite tungsten dioxide powder, heated to 580 °C for 10min, then heated to 630 °C for 10min, then heated to 680 °C for 10min, then heated to 730 °C for 10min After that, the temperature was raised to 680°C. and kept for 10 minutes to obtain a rare earth composite tungsten dioxide powder having a particle diameter of 0.3 um to 0.4 um.

3.A rare earth tungsten alloy powder with a particle size of 30nm to 40nm is obtained by adding the treated rare earth compound two tungsten oxide powder to the high energy ball mill.

4.The nanocrystalline rare earth tungsten alloy powder treated by internal pressure is made into nano rare earth tungsten alloy billet.

5.The nanocrystalline rare-earth tungsten alloy strips are sintered in a medium frequency induction furnace until the nano rare-earth tungsten alloy rods with a density of 18.3kg/m3 or more are sintered.

6.The nanocrystalline rare earth tungsten electrode was prepared by forging and stretching the treated nano rare-earth tungsten alloy rod at high temperature.

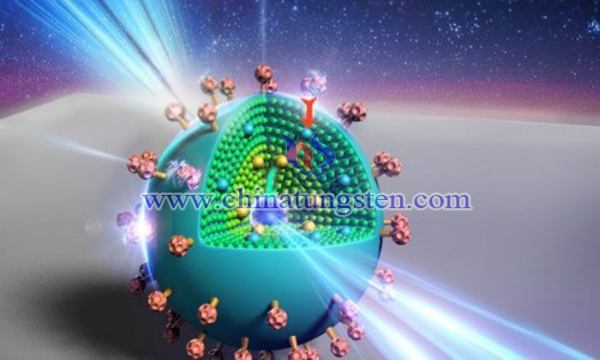

Nanometer rare earth tungsten electrode is made of nanometer powder. Because the active substance is refined in large area, the migration and diffusion rate of the surfactant of nanometer rare earth tungsten electrode are improved. The surfactant is in a wide range of temperature, which improves the current density of zero field emission of tungsten electrode and reduces the burning loss rate.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com