η Phase of WC-Co Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 March 2018 14:51

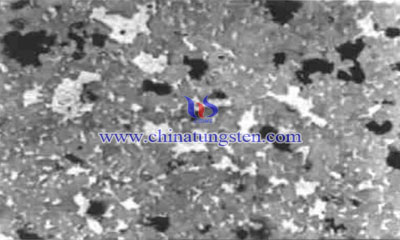

With its excellent properties, WC-Co tungsten carbide becomes the most common tungsten carbide material, which can be obtained by powder sintering. In actual production, this kind of tungsten carbide is not only composed of γ +WC phase. η phase, the lack of carbon phase is one of the most common phases. Mostly, η phase is a kind of malignant defects in the alloy, which makes the physical and mechanical properties of the alloy become very poor.

Types of η Phase

The carbon content in the WC+ γ two-phase region is very narrow. In the actual production conditions, raw materials or sintered carbon medium alloy decarburization often makes the insufficient carbon content of M6C or η phase of M12C type. Theη phase types of type M6C can be divided into Co3W3C (η1) and Co2W4C (θ). And η phase of M12C can be divided into: Co6W6C-F, Co6W6C-104F(η2), Co3W9C4, Co3W6C (η1), Co2W8C3 and Co3W10C4. Due to the industrial production of alloy, η1 is the most common phase. And its detection means are more improve, so the η1 phase is the most popular phase to discuss.

Causes of η Phase

In the actual production conditions, the decarburization of raw materials or sintered carbon medium is the common cause of η phase. The speed of W diffusion from WC grains to γ phase is slower in WC-Co tungsten carbide, so the W concentration in the WC- γ phase boundary is higher than that of the γ phase. The η phase crystal billet along the WC- gamma phase boundary and the WC grain surface for heterogeneous nucleation core.

There are a large number of small size WC grains in the γ phase of WC-Co tungsten carbide. As the C atoms diffuse faster in the γ phase, when WC dissolves in a single atomic form, the C atoms will escape from the alloy from the γ phase. The W solute in γ phase of WC+γ+η1 three-phase alloy is always overdose compared to C solute. And the [W]/[C] value is stable at 2.84.

At the sintering temperature (1350~1500℃), the solute concentration of W and C in the balanced γ phase has a corresponding stability value. If the concentration of C loss too much, is missing carbon η 1 phase. In the heating process, the intermediate formation of Co3W and Co6W6C firstly occurs, and η1 phase will only appear at high temperature.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com