Phase Composition of WC-Co Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 March 2018 14:48

WC-Co tungsten carbide is a kind of widely used material, which has many advantages, such as high hardness, good wear resistance and so on. Its properties depend not only on the grain size and cobalt content of WC, but also on the phase composition, microstructure and existing form of the material.

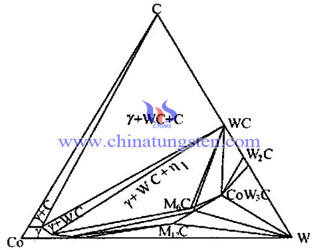

In actual production, due to the influence of raw materials and sintering technology, the alloy usually contains more complex structure. In addition to the normal WC phase, there are also γ phase and η phase of WC in Co. The γ phase and η phase is two important phase components. Based on the W-Co-C phase diagram, the phase composition of the WC-Co alloy should be discussed from the thermodynamic point of view.

W-C-Co Ternary System Phase

The WC-Co tungsten carbide is actually a W-Co-C ternary system. WC+γ+C or WC+γ+η ternary system phase will form in the sintering temperature, due to the presence of a small amount of free carbon. The alloy strength is closely related to the struct and composition of η phase. And the existence of η phase may lead to poor toughness of the alloy, so people in the alloy phase and phase transition process, γ、η conducted a lot of research, trying to control the phase composition of WC-Co alloy, in order to improve the comprehensive properties of WC-Co alloy.

η Phase

The width of carbon content in WC-Co tungsten carbide (WC+ γ region) is very narrow. Under the conditions of industrial production, it is unavoidable that the carbon deficiency of raw materials or the decarburization of the sintered medium is unavoidable because of the process out of control. So the η phase of M6C type or M12C type often can be seen in the WC-Co tungsten carbide products.

γ Phase

The γ phase in WC-Co tungsten carbide is a Co based Co-W-C solid solution. In the tungsten carbide it is composed of γ grains separated by the grain boundary or the γ crystal domain inhomogeneous in the matrix in the form of an isolated island. Both γ grain and γ crystal domain are equiaxed or near equiaxial. With the increase of the Co content in the alloy, the volume fraction of the γ crystal domain also increases.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com