Mechanism of Solid Phase Sintering

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 February 2018 14:27

After the two stages of particle rearrangement and dissolution-reprecipitation, the densification process has slowed obviously. Because the pores have basically disappeared, the distance between the particles is narrower, making it more difficult to flow into the pores. Then the particles are drawn close together, and the sintering is entered into the phase of solid phase sintering, forming the skeleton.

During the solid phase sintering, the residual liquid is filled with the gap of the skeleton. When the liquid phase is not completely wetted, the amount of solid phase or liquid phase is very small. The result is that a large number of particles are directly contacted and not covered by liquid phase.

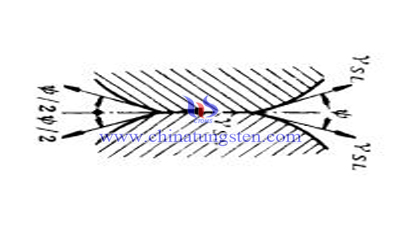

In this stage, γss/2<γsl or dihedral angle ψ>0. The sintering process after the formation of the skeleton is similar to the solid-state sintering, and the densification has slowed down significantly.

Solid Phase Sintering Stage of Tungsten Carbide

According to the classical solid-state sintering theory, tungsten carbide will undergo three stages: particle bonding, sintering neck growth, spheroidizing and shrinking of closed pores during solid phase sintering. When the particles are bonded, the grains in the particles do not change, and the shape of the particles is basically unchanged. The whole sintered body does not shrink, but the strength between particles is increased.

During the growth stage, the distance between particles decreases, forming a continuous pore network. At the same time, as the grain grows, the grain boundary moves across the pores, and the pores disappear when the grain boundary is swept away. The shrinkage, density and intensity of the sintered body increase significantly.

Finally, due to the growth of the neck of sintering, the pores which are initially connected with each other gradually shrink into closed pores, and the pore shape approaches spherical and decreases. Finally, the densification process is completed. Solid phase sintering of tungsten carbide is composed of two stages. One is solid phase sintering, which occurs before liquid-phase sintering. One is solid phase sintering caused by liquid particle sintering rearrangement and contact.

Characteristics of Solid Phase Sintering

1,Compared to the above two stages, this process is slow.

2,The phenomenon of contact flatness and grain growth of solid particles occur (the rigid skeleton formed to prevent densification).

3,Spheroidization occurs in non-contact areas (less liquid phase).

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com