Sintering - Rearrangement of Particles

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 February 2018 14:35

During the sintering, there will be stages of liquid phase formation, rearrangement, dissolving-reprecipitation and solid phase sintering. After the liquid phase is generated, it flows under the influence of pore pressure difference and capillary force, which makes the solid particles suspended in the liquid phase rearrange. It is the mechanism of particle rearrangement in liquid sintering.

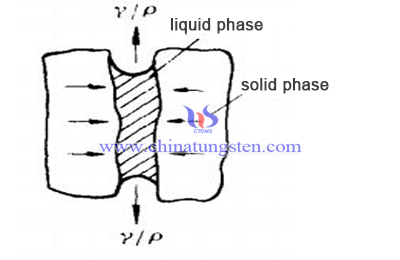

In the presence of liquid phase, particles suspended in a liquid phase approximation. It is driven by the surface tension of the liquid phase. The capillary force formed by the liquid phase in the intergranular pores and the viscous flow of the liquid phase make the particles adjust position and redistribute to achieve the closest arrangement.

Stomatal Pressure Difference

Driven by the capillary force, the particles are rearranged to obtain the most compact and minimum pore total surface area. To meet the thermodynamic condition γs>γl>γss>2γsl, the solid gas interface gradually disappears when the liquid and solid particles infilter into the wetting gap.

When the liquid phase completely surrounds the solid particles, there are still large and small pores in the liquid phase. Because the stress on the pore of the liquid phase is different from that of pore size, the pressure difference acting on the size pores will drive the liquid phase to flow between these pores, which is also known as liquid viscous flow.

Capillary Force

Because of the capillary tension γ/ρ, the particle clearance into the liquid phase produce the force that makes the particles close together. Due to differences in the size and shape of solid particles on the surface, the capillary radius of curvature concave liquid phase is not the same. It makes every particle and its capillary force and its component unequal, and makes particles move in the liquid phase.

The rearrangement of particles is successfully completed. After that, the best packing state (close packing) is achieved, while the densification complete. The liquid-phase flow and particle rearrangement caused by the capillary force are the main mechanism of the liquid-phase sintering.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com