Sintering - Surface Diffusion

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 22:32

Sintering is the most important process in the production of tungsten carbide, which has an important influence on the performance of the product. The study of the material migration in the sintering process is helpful to the effective formulation of the sintering process. In these material migration mechanisms, surface diffusion plays an important role in the migration of material.

The evaporation and aggregation mechanism are based on the fact that the powder has a large saturated vapor pressure at high temperature. However, the migration of particles through the surface layer of the particles can accomplish the migration of matter, but it can happen at a much lower temperature. In fact, during the sintering process, the interparticle association is first carried out on the surface of particles. Due to the diffusion of surface atoms, the bonding surface of particles is enlarged, and the concave surface of particles is gradually filled.

Maximum surface area and high surface energy of the powder are the thermodynamic nature of all the surface phenomena (including the surface atom diffusion) of the powder. Surface diffusion is of special importance to the migration of material before the isolated closure is completely formed in the sintering body.

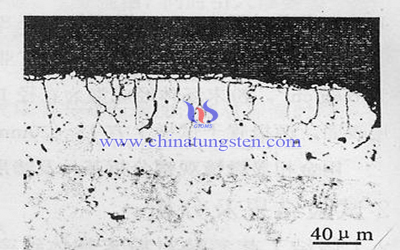

Scholars believe that the effect of surface diffusion is very significant at low and medium sintering temperatures. At higher temperatures, it is gradually replaced by volume diffusion. In the early stages of sintering, there were a large number of connected pores. The surface diffusion makes the pores shrink and disappear, and the micropores increase.

Therefore, the total pore volume and volume decrease, and at the same time, obvious shrinkage occurs. However, after the formation of isolated closed pores at the late stage of sintering, surface diffusion only promotes pore surface smooth and pore spheroidization but has no effect on the disappearance of pores and the shrinkage of sintered bodies.

The velocity equation of the surface diffusion is as follows:

x7/a3=(56Dγδ4/kT)*t (1)

Where,

x--Radius of the sintered neck,

γ--Surface tension,

a--Radius of powder particle,

k--Boltzmann constant,

δ--Lattice constant,

T--System temperature,

t--Sintering time.

Basic View of Surface Diffusion:

1. At low temperature, surface diffusion plays the leading role, and the dominant effect of volume diffusion mechanism at high temperature.

2, The surface diffusion of particles with fine particles is large.

3. Pores are connected in the early stage of sintering, and the result of surface diffusion leads to the reduction and disappearance of the small pores, and the large pores grow up.

4, The surface of the metal powder has a small amount of oxide and hydroxide, and it can also play a role in promoting the surface diffusion.

5.Surface diffusion in the later period of sintering leads to pore spheroidization.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com