Sintering - Volume Diffusion

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 22:28

Sintering process of tungsten carbide is accompanied by material migration, of which the transfer of material by atom diffusion also plays an important role. Material diffusion is caused by the difference in the degree of the degree caused by the concentration gradient of the vacancy.

The diffusion process of sintering is described in detail in many research work, of which the kinetic equation of sintering is derived by applying the diffusion equation. Volume diffusion is a very important kind of diffusion mechanism.

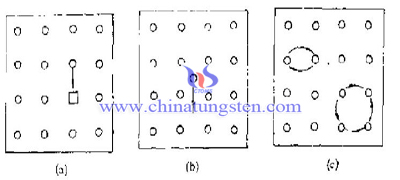

According to the classical theory of sintering and diffusion, there exist excess vacancies above the equilibrium concentration in the crystal, which is the force leading to the directional migration of vacancies or atoms. Further theory adds that during the late sintering stage, the surface stress increases the vacancy concentration in the material around the closed cell, and continuously diffuses outward to the sintering, causing pore shrinkage.

Diffusion theory holds that the growth of the cervix is the diffusion of the vacancies near the neck surface to the sphere, and the result of the migration of the atoms inside the sphere to the neck. In addition, there are also interatomic diffusion and interatomic transposition or ring transition positions.

In fact, the space source is not only the surface of the sinter neck, but also the small pore surface, the concave surface and the dislocation. Correspondingly, there are grain boundary, plane, convex surface, large pore surface, dislocation, etc. Relative to the inner pores or the surface of the sintered neck and the large pore relative to the small pores, the surface of the particle can become a hole in the void. Therefore, when the vacancy is diffused from the inner pore to the particle surface and the vacancy is diffused from the small pore to the macropore, the sinter will shrink, the small pore will disappear, and the average pore size will increase.

If the bulk diffusion is the main type of sintering, the formula is as follows:

x5/a2=At

Where,

x-- Radius of sinter neck,

a-- Radius of powder particle,

B-- Coefficient,

t-- Sintering time.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com