Sintering - Boundary Diffusion

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 22:35

In the production of tungsten carbide, sintering is a very important process which has a great influence on the properties of products. Material migration is accompanied by the sintering process, of which the diffusion mechanism plays a very important and important role. Boundary diffusion is a kind of diffusion mechanism, which is of great significance to sintering.

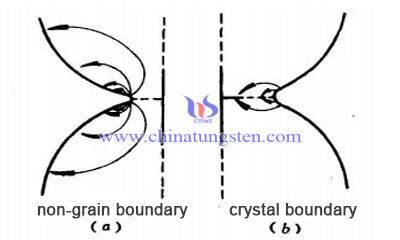

The grain boundary will play a role in the growth of the sintered neck and the contraction of the sintered body. During the vacancy diffusion, it can be used as an empty "trap", and it plays an important role in many reactions or processes.

1, When sintering, it is easy to form stable grain boundaries on the particle contact surface. Especially after fine powder sintering, many grain boundaries and pores are interlaced, so that the excess vacancies on the edge of the sintered neck and the fine pore surface are easily diffused or absorbed by the neighboring grain boundaries.

2, The activation energy of grain boundary diffusion is only half of the product diffusion, and the diffusion coefficient is 1000 times larger than that of the diffusion coefficient, and the difference increases with the temperature decreasing.

3, When fine powder is sintered, it plays the leading role at low temperature and causes the volume contraction.

If the grain boundaries are not formed on the surface of the particles, the vacancy can only spread from the sinter neck to the surface of the particles. Namely, the atoms fill the sinter neck from the surface of the particles. If the grain boundary exists, the excess vacancies on the edge of the cervix will disappear into the grain boundary, and the result is that the spacing of the particles is shortened and the contraction occurs.

Diffusion Mechanism of Vacancy to Grain Boundary

1, The space around the pores on the grain boundary is diffused along the grain boundary (the space well) and absorbed by it, reducing the pores and contracting the sinter body.

2, The diffusion channel diffuses to the two ends, which disappears outside the sintered body. And it will make the pores shrink and the sinter bodies shrink.

Diffusion Equation of Grain Boundary Diffusion

1, According to the two-ball model, the formula is as follows:

x6/a2=(960Dγδ4/kT)*t (1)

2, The grain boundary diffusion equation derived from the ball plate model is as follows:

x6/a2=(12Dγδ4/kT)*t (2)

Where x-- Radius of sinter neck,

γ-- Surface tension,

a-- Radius of powder particle,

k-- Boltzmann constant,

δ-- Lattice constant,

T-- System temperature,

t-- Sintering time.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com