Viscous Flow of Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 22 January 2018 22:21

The sintering process of tungsten carbide is actually a process of material migration. During the sintering process, the amount and quality of particles on the bonding surface and the spheroidization and shrinkage of the pores in the sintering body are all based on material migration.

At the early stage of sintering, migration mainly shows as viscous flow. Other forms of material migration, such as diffusion, evaporation and condensation, and flow, are mainly caused by high enough temperature or external force.

The bond between the particles in the initial stage of sintering has the properties of van Edward force and does not require an obvious displacement of the atom. It only involves the adjustment of the change or position of the part of the atomic arrangement on the surface of the particle, which needs low activation energy. So, the bond can occur even at low temperature and short time. It is the main feature of the early sintering, and the shrinkage of the sintered body is not obvious at this time.

1, Frelen Kerr Ball - Spherical Model

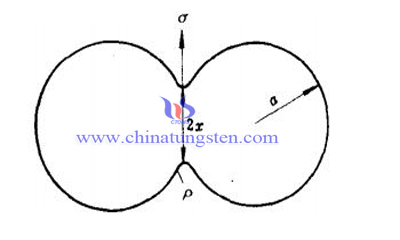

The viscous flow model was proposed by Fred Kerr in 1945. He divided the sintering process into two stages. In the first stage, the contact surface between adjacent particles is increased until the pores are closed, and the remaining obturator gradually decreases in the second stage.

For the first stage, the velocity equation for the uniform growth of the radius X of the radius of the sinter neck.

x2/a=3/2*γ/η*t(1)

Where: a-- Particle Radius,

γ-- Surface Tension,

η-- Coefficient of Viscosity.

Kerr believes that the viscous flow of the crystal is accomplished by self - diffusion of the empty space in the body. The relationship between viscosity coefficient (η) and the diffusion coefficient (D) is 1/η=Dδ/kT(2)

Where: δ-- Lattice Constant,

k-- Boltzmann Constant,

T—Temperature.

2, Kuchinski Sinter Ball Plate Model

Based on the flow model of homogenous viscoelastic material, a kinetic equation for the growth of sintered neck is derived.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com