Sintering Driving Force - Vacancy Concentration

- Details

- Category: Tungsten Information

- Published on Monday, 22 January 2018 22:18

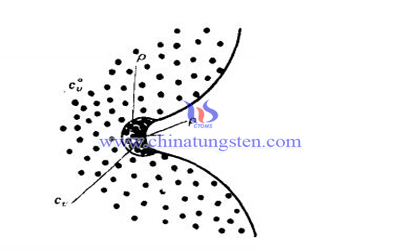

Surface tension causes the macroscopic flow of the material to the pores at the neck of the sinter. Additionally, when the crystal powder is sintered, there is also a migration of atoms caused by the concentration gradient of the vacancy concentration. The ideal sphere model can be used to calculate the gap concentration difference caused by the diffusion in the sintering system.

Tensile Stress of Surface During Sintering

σ=-γ/ρ(1)

The effect of tensile stress on the sintered neck surface changes the distribution of the original vacancy concentration in the burnt ball. It changes the formation of the vacancy.

Thermal equilibrium concentration of vacancy in crystal according to statistical thermodynamics is as follows:

Cv=exp(Sf/k)*exp(-E'f/kT)(2)

Where Cv-- Thermal equilibrium,

Sf-- An increase in entropy (vibration entropy) of the vibration of the surrounding atoms caused by a vacancy,

E'f-- Under stress, the energy required to generate a vacancy (vacancy generation energy) in a crystal is produced.

The tensile stress σ changes the energy required to generate a vacancy, which is equal to the work done by the stress to the volume of the vacancy.

σΩ=-γΩ/ρ(3)

Where Ω - the volume of a vacancy.

A negative sign means that tensile stress reduces the tension of vacancy generation. In the crystal tensile stress area, the vacancy concentration will be higher than other area.

So, the energy required to form a vacancy in the stress region should be:

E'f=Ef±σΩ(4)

Where Ef - Vacancy generation energy in ideal complete crystal (no stress).

σΩ/kT《1,exp(±σΩ/kT)≈1±σΩ/kT,

Cv tensile stress =Cv(1+σΩ/kT)

Cv compression stress =Cv(1-σΩ/kT)(5)

The concentration difference between the two equilibrium vacancies is:

ΔCv=Cv (tensile stress) -Cv=Cv*σΩ/kT=Cv*γΩ/kTρ(6)

It is shown that the concentration gradient of excess vacancy will cause the diffusion of vacancies to the sphere in the small area under the surface of the sintered neck. Thus, the migration of the atoms to the opposite direction makes the neck grow. It is the basic formula for the study of the application of the sintering mechanism.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com