Purple Tungsten Oxide In-Situ Reduction Method

- Details

- Category: Tungsten Information

- Published on Sunday, 14 January 2018 13:49

Ultrafine tungsten carbide and its raw materials have provided a strong impetus for the production technology progress of Chinese efficient cutting tools. In the past, there are some shortcomings in the preparation of ultrafine tungsten carbide. And the purple tungsten oxide in-situ reduction method is a more effective method.

The domestic and foreign materials scholars have excogitated a lot of methods for the production of ultrafine tungsten powder and WC powder. Methods mainly are low temperature reduction and carbonization, oxide direct carbonization, plasma chemical - carbonation, carbonation, halide salt precipitation etc. There are three main categories: (1) ultrafine tungsten powder is first prepared and then carbonized to obtain ultrafine WC powder; (2) direct carbonization of tungsten compounds; (3) WC-Co composite precipitation.

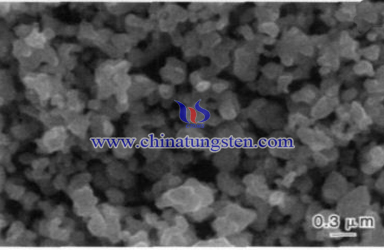

Principle of purple tungsten oxide in-situ reduction method is as follows. Nano purple tungsten oxide has huge specific surface area and sharp instability. It is rapidly reduced into superfine tungsten single crystals with beads under the effect of high temperature hydrogen. This method inhibits or weakens the migration of chemical vapor phase, thus restraining the grain growth of ultrafine tungsten powder.

Using single phase ultrafine tungsten powder and carbon black as raw materials, the mixture is carbonized at high temperature. And the raw materials are simultaneously carbonized into ultrafine tungsten carbide powder by the weak heat release in carbonization reaction.

Characteristics

This method avoids the defects of the product's impure. Compared with other methods, the product produced by this method also has great superiority.

1, The distribution of granularity is more concentrated, which is a result of the single phase of the purple tungsten oxide. Powder made from purple tungsten oxide is small and uniform. Moreover, the particle size distribution is narrow and there is no structural aggregation.

2, It can not only produce ultrafine tungsten powder, but also produce ultrafine WC powder.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com