Spherical Tungsten Powder Preparation

- Details

- Category: Tungsten Information

- Published on Saturday, 06 January 2018 22:07

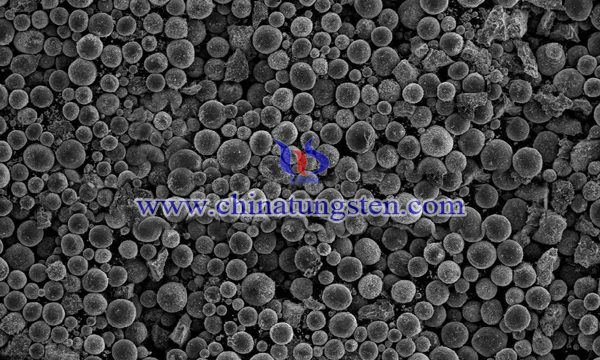

In the field of electronics, such as the preparation of electric vacuum device with high emission rate of tungsten based cathode materials, in order to meet the requirements of higher quality performance reserve type cathode material, tungsten powder, which is more narrow in grain size and more slippery on the surface of the particle, should be used as a raw material than the present polygonal tungsten powder.

Because porous tungsten matrix prepared by spherical compact tungsten powder can provide enough storage space and migration channel for the barium emitting material, which can effectively improve the emission current density and improve the performance of the whole cathode assembly.

In the field of thermal spraying, compact spherical powder is the basis for forming uniform coating. Because of its good fluidity, the spherical tungsten powder is more uniform and compact. Meanwhile, the finer powder can get more compact coating and improve the wear resistance and heat resistance of the coating. In powder metallurgy process, the powder metallurgy compact made of spherical tungsten powder on the one hand is very uniform in the sintering process, and can achieve good size control. The rocket nozzle bushing made of spherical tungsten powder has good fracture resistance and corrosion resistance under thermal stress. As a large country of tungsten resources, the research and development of high-performance spherical tungsten powder is very important for China to play the dominant resources and promote the development of China's material industry.

The success of spherical tungsten powder preparation methods are: 1, plasma CVD; 2, plasma spheroidization; 3, tungstate precipitation reduction method, the method of equipment is extremely high, the cost is higher or the production of environmental pollution is serious, and preparation of spherical tungsten powder prepared by the the particle size distribution in 1.2~2.8 micron limited. Recently, some scholars have proposed a preparation method of near spherical tungsten powder, which has good shape distribution uniformity, simple technology, low production cost and suitable for industrial production.

The treated tungsten powder is oxidized. Because the tungsten powder has larger surface area and larger active angle, the oxidation rate of the tungsten oxide will be much higher than that of the flat surface. After washing out the prominent part and edge of the local preferential oxidation, the near spherical particles are formed more smooth than the surface of the original tungsten powder. The near spherical tungsten powder prepared by the method has the advantages of good shape distribution uniformity, and the invention has the advantages of simple process, low production cost and suitable for industrial production.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com