Application of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Saturday, 06 January 2018 17:05

With the development of technology, the application of tungsten carbide die gradually extended from drawing die to stamping, forming, punching, blanking and extrusion die. Mould is an indispensable important equipment in modern industry, of which tungsten carbide is a very ideal and superior material. For more than 10 years, tungsten carbide dies are applied not only to cold working, but also to hot forging and hot rolling.

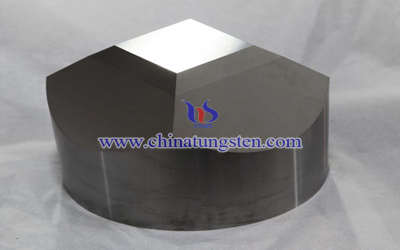

1, Tungsten Carbide Anvil

Tungsten carbide anvil is an important component of the production of artificial diamond, which receives alternating load of high temperature and high pressure in the process of diamond synthesis. The length of its life directly determines the production cost of diamond synthesis. Grades for the tungsten carbide anvil include YG6, YG8, YG12x and so on.

2, Tungsten Carbide Drawing Mold

A lot of tungsten carbide die is acquired in the metal drawing production. Tungsten carbide drawing mold which is made of high quality tungsten carbide has high hardness, good thermal conductivity and low coefficient of friction. Presently, the main brands of tungsten carbide drawing die in China are YG8, YG6, YG3 and so on.

3, Cold Heading, Cold-Punching Mould, Sizing Die

It is important for large batch stamping parts to figure out the way to prolong the life of stamping die and improve the productivity. The die life can be prolonged by improving the manufacturing process and improving the die structure.

Using the tungsten carbide material with high hardness and good wear resistance to replay the alloy tool steel with is an important and effective way. At present, the main brands in China are YC20C, YG20, YG15 and YJT30, etc.

4, Nonmagnetic Alloy Die

Nonmagnetic alloy is a tungsten carbide material without magnetic or weak magnetic properties. It is mainly used in the production of magnetic materials. In the production of magnetic materials, nonmagnetic tungsten carbide can double the efficiency of the work, due to its excellent performance.

5, Heat Forming Die

The roll of a high-speed wire rod mill is a product with a groove or a rolling hole. When working, the steel billet at 1000~1100℃ passes through at the speed of 70 to 120m/min, to get the thermal stress at high temperature and high frequency. So, it is a fragile component. The use of tungsten carbide material can meet its performance requirements.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com