Tungsten Carbide - Die Bushing

- Details

- Category: Tungsten Information

- Published on Thursday, 04 January 2018 18:36

Because of the particularity of the tungsten carbide, its price is high. In order to reduce the cost of the mold, it is often used in the most critical parts of the production process - the structure of the mold with the inlaid hard alloy components.

Die structure and its processing method are simple, which has been widely used in molding, drawing and other working procedures. The die bushing of tungsten carbide mold can be done by melting copper and hot charging, or by physical cold extrusion (screw extrusion and fixation).

1, Welding and Hot Charging of Molten Copper

The traditional cemented carbide die inserts are traditionally used for welding and hot charging. According to the steel material which is cooperated with the hard alloy, the reasonable amount of interference is selected, and the assembly surface is processed separately, and then the welding is assembled. And the thermal loading process is also different according to the coated cemented carbide as the jacket or inner sleeve.

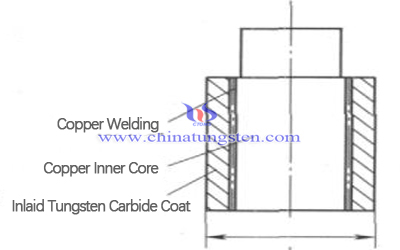

1.1, Inlaid Coat

It usually welds with molten copper. Generally, the gap coordination is used, which is the smooth flow of molten copper into the gap. If the interference fit is used, the surplus should be little to prevent crack. In order to remove the internal stress, the copper is kept warm after welding. And the oven is placed in the oven or embedded in the better insulation material and slowly down to room temperature.

1.2, Inlaid Inner Sleeve

In order to prevent the loosening in the process of use, interference fit is usually used. When pressing the heating steel jacket is into the inner sleeve of the tungsten carbide, the amount of interference should be made in a reasonable hole to prevent the oversized steel jacket.

2, Physical Cold Extrusion Fixation

It is fixed by physics of cold extrusion and with small interference volume. With the use of fine thread extrusion and fixation, the locking anaerobic adhesive is added to the joint of the thread.

The welding and hot charging of molten copper are the traditional assembly way, which is simple in structure and low in production cost. Its drawback is that, whether it is hot or copper welding, more or less, the microstructure of the cemented carbide material will be disadvantaged. And in the process of use, it is easy to break up and break off.

Physical cold extrusion can avoid the influence of high temperature on the mold material and ensure the stability of the mold during the use process. Its shortcoming is that the manufacturing process is more complex and the processing technology is more demanding.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com