Green Body Presintering Process

- Details

- Category: Tungsten Information

- Published on Sunday, 19 November 2017 23:41

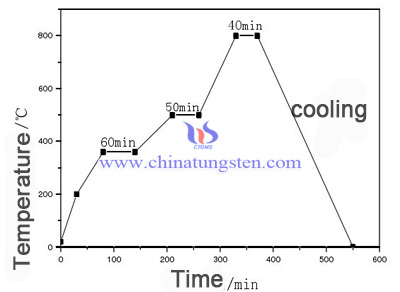

Improving the strength of tungsten carbide green body is the key to achieve the processing requirements. Presintering can enhance the strength, which is one of the most important processes in the production process of tungsten carbide.

Actually, the low temperature sintering stage can be taken as a separate process, that is, pre-sintering. It can be either a technological stage or an independent process in the whole sintering process. For green processing, presintering refers to an independent process. The presintering temperature is usually below 1000℃.

According to the theory, the main changes occurring in the presintering process are:

1, The residual stress in the green with the rising of sintering temperature decreased gradually;

2, Adsorbed moisture is volatilized as the temperature rises;

3, The forming agent is volatilized or pyrolyzed with the increase of temperature;

4, When the temperature is above a certain temperature, the welding phenomenon begins between the cobalt powder particles and the tungsten carbide particles. Since the "welding" has just begun, at this stage the product shrinkage is not significant (general shrinkage is about 0.8%).

The strength of the product begins to increase, although it is not significant, but it can meet the requirements of cutting. In this stage, the solubility of tungsten carbide in cobalt is less than 4%, so the diffusion of tungsten carbide into cobalt is not active, only diffusion on the surface of tungsten particles.

Accordingly, through the presintering process control the presintering strength control in a certain range, to meet the requirements of machining. The sintering temperature cannot be too high, and the welding between the cobalt powder particles and the particles occurs.

In the process of cutting, the tool cuts the bonding and pores which are just bonded together, so that the tool can avoid the tungsten carbide particles with high hardness and reduce the wear of the cutters.

When the sintering temperature of the pre sintered billet is greater than 950℃, the strength will increase to 80Mpa. This means that the diffusion of atoms is very fast, and sintering has become perfect, so machining will lead to direct contact between tools and tungsten carbide, and reduce the tool life.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com