Preparation of Pre-Sintering Process

- Details

- Category: Tungsten Information

- Published on Sunday, 19 November 2017 23:37

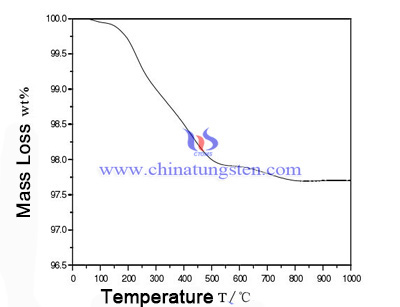

The forming of tungsten carbide requires molding agent. For the green body which need pre-sintering, the formulation of the process is mainly based on the effective removal of the molding agent. In order to effectively evaluate the removal efficiency of molding agent, thermogravimetric analysis is often used.

Process Requirements of Pre-Sintering

A certain amount of forming agent will be added in the compacting process of cemented carbide. Although the volatility is different, with the increase of temperature, most or most of the forming agent will evaporate at this stage, leaving only a small amount of carbon in the product.

The heating rate must be properly controlled according to the forming agent used. If the heating is too fast, the volatilization of forming agent will be too fast, which may cause peeling or blistering cracking of the product. Moreover, when the molding agent is too volatile to decompose into carbon, it will increase the free carbon content of the product, reduce the density, strength and hardness of the product.

If the heating is too slow, the forming agent will not be volatilized completely into the high temperature zone. The residual forming agent will still occur near the high temperature volatilization too quickly, product bubbles and pyrolysis cracking into carbon in the product.

Take a brand of tungsten carbide thermogravimetric analysis as an example, this is the thermogravimetric analysis curves. It can be seen from the thermogravimetric curve that the forming agent begins to decompose at 160℃ and the mass loss increases sharply at 200℃, which indicates that the decomposition speed of the forming agent is accelerated.

When the temperature is 500℃, the weight loss of pre-sintered blank reaches 2.0wt%, and the decomposition of molding agent is basically completed, and the change of thermogravimetric curve is gentle. When the temperature reached 800℃ and the pre-sintered blank weight reached 2.3wt%, the thermogravimetric curve remained unchanged, indicating that the forming agent was completely removed after the temperature.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com