Tungsten Carbide Green Strength

- Details

- Category: Tungsten Information

- Published on Sunday, 19 November 2017 23:34

As an important indicator of the performance, green strength of tungsten carbide is the ability to resist external force pressing blank keeps its original shape and size. It is often used to measure the transverse fracture strength of rectangular specimens. The strength in the pre-burn before the main bond forming agent, debinding together after provided by atoms.

Green Strength Measurement of Tungsten Carbide

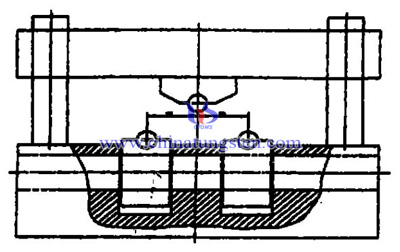

According to GB/T5160-1985, the strength is measured by using the transverse rupture strength of rectangular blank samples (pictured above), the calculation formula is as follows:

S=3Pl/2t2W

Where:

S…Compacting Strength (N/mm²) ;

P…The force required for fracture(N);

l…Fixture span(mm);

t…Sample thickness(mm);

W…Specimen width(mm).

Green Strength Change of Presintering Process

Tungsten carbide is hard particles and its intensity mainly depends on the bond forming agent, so the mechanical meshing between the particles and the particle force is very small. According to the TG curve, forming agent volatilization at 500℃, and the linked relay which determines the green strength disappeared.

When the atomic surface diffusion rate is low, the binding force between atoms is difficult to provide enough strength. Therefore, the apparent strength of pre sintered compacts is relatively low under sintering at 720℃. With the increase of temperature, the rate of atomic diffusion is further improved. When the temperature is above 720℃, the welding phenomenon occurs between the cobalt powder particles and the particles. In this stage a contraction in the green body begins to take place and the strength began to increase.

Strength Requirement of Green Processing

To make the tungsten carbide billets with machinability, general requirements for blank strength can reach above 30Mpa. But too high strength will lead to direct contact between tool and tungsten carbide, and reduce tool life.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com