Injection Molding: Thermal Debinding Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 October 2017 23:20

Injection molding of cemented carbide belongs to the powder injection molding process (PIM), which is complex and has many influencing factors. Improving and stabilizing the properties of cemented carbide during the PIM process is always the most difficult point in PIM process.

The binder removal process is very harsh, requiring neither carbon nor decarburization. Otherwise, the mechanical properties of the sintered products will be greatly affected. As the final step of two step debinding process, the technological parameters of thermal debinding directly affect the quality of cemented carbide injection blanks.

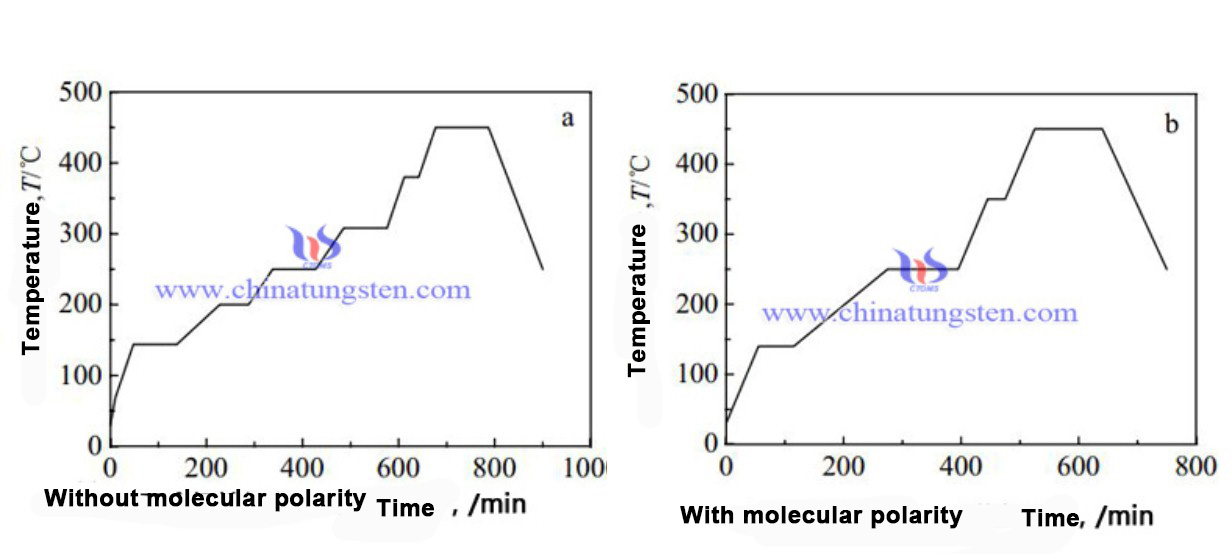

1, Without low molecular polarity component

At present, binders for paraffin based multi-component system are widely used in the injection molding industry. These systems, such as PW-EVA-HDPE binder system, do not contain low molecular polarity components.

The main component wax of this kind of binder usually softens and melted at 55 ~70 C, but it will not be removed below the melting point. When the temperature is above a certain temperature (the lowest pyrolysis temperature of PW component), PW begins cracking and produces a large amount of gas. At a fast heating speed of the blank temperature to high temperature (200-250℃), injection molding is easy to crack. When the heating rate is low, no blank skim defects, most PW can decompose. If the thermal debinding temperature is higher than 450 ℃, the binder is removed, and the WC is decarburization. Therefore, the maximum temperature of thermal debinding should not be higher than 450 degrees.

2, With low molecular polarity component

In cemented carbide injection molding, WC has small particle size, irregular shape, large specific surface, high surface activation energy and large degree of powder agglomeration. Organic compounds (especially surfactant components) are easy to form a layer of adsorption film on the surface of powder particles or agglomerated powder particles, of which the thickness has a great influence on the removal of binder.

Low molecular polarity component such as oil, stearic acid, ortho two, two and so on, have polarity, preferentially adsorbed on the surface of WC powder, more evenly coated on the powder surface, and reduce the thickness of the adsorption layer. Moreover, these low molecular binder components are more easily removed by thermal debinding than paraffin.

Therefore, the thermal debinding time of the injection blank containing the low molecular polarity component is short, the process parameters are not very sensitive, the degreasing defects are easy to control, and the thermal debinding process control steps are simple.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com