14 Stop Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 16:26

14 Stop tungsten dart rule is an easy and fun game that may be played by as many teams as wish to play. It is almost the same game as regular Baseball with a twist to make it more interesting.

The Object: The object is simple: score the most amount of runs each inning, the highest score at the end of the game wins.

The Scoring: The numbers 1 through 9 are written in ascending order on the left side of the scoreboard. All players names are written in batting order across the top (batting order may be determined any way, usually one tungsten dart each at bulls-eye with the closest throwing first and the furthest last). A grid may be drawn around the numbers and the names for easier reading.

The Play: One player on each team is chosen to hit the 14's and the other to score the runs.

The 14 shooter always throws first in each inning, trying to throw as many 14's as possible.

Each scorer then throws three tungsten darts at the number of the current inning. If no 14's were hit by the 14 shooter, the score for the inning is zero. The target is 1's in the first inning, 2's in the second, etc. Each number only counts in that actual inning. For example, if a 4 is hit in the first inning, it does not count. The thin outer "double" ring counts as two runs, the thin inner "triple" ring counts as three runs with the other sections of that number counting as one run. The score is multiplied by the number of 14's hit by the 14 shooter. Therefore, the highest attainable score in any one inning is 81 (three triple 14's=9 and three triples by the scorer=9, 9x9=81).

The number of runs scored is not multiplied by the inning number. For example, in the second inning, the 14 shooter hit one 14 and the scorer hit two single 2's; that players score would be two for that inning.

Usually a running total is kept with the current inning's score being added to the current total. This way, players can see how far ahead or behind they are and save a lot of time not having to add all nine innings at the end of the game.

If there is a tie at the end of the ninth inning, extra innings are played with bulls-eyes as the target. Extra innings continue until after all players have thrown for that inning and no tie exists.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Advanced Strategies for 501 Tungsten Darts Ⅱ

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 16:24

The game of 501 tests your ability to consistently hit high numbers every time you step up to the line. The main thing to remember is to relax and trust your game. It also helps to memorize all of the tungsten dart sequences for your out numbers. Here are some tips that can teach you advanced strategies for 501 tungsten darts.

Work on slowing down your breathing. You just hit a ton-40 and everybody gives you a high-five. Your adrenaline is pumping, you feel like you can conquer the world. Then you step up the line for your next shot and you throw a bag of nails (11 shot). What happened between these two turns? You got pumped up and full of energy, that's what happened. This change in demeanor can alter your throw. Relaxed and calm is how you want to be on the line. Just take a few deep breaths between shots, forget about your last throw and visualize your tungsten darts in the triple ring.

Follow your aim. Sometimes you can find yourself throwing poorly because you are trying too hard to aim your tungsten darts. Concentrating too hard on each dart’s destination can cause you to get tense and can easily spiral out of control. You might even find yourself battling darts. Consider focusing your aim on your first dart and then use that dart as a marker dart. As long as that first dart is a good shot, all you have to do is repeat your throwing motion at your marker dart. By not having to concentrate on aiming every tungsten dart you can maintain a relaxed and calm state of mind, which is the key to throwing great tungsten darts.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Advanced Strategies for 501 Tungsten Darts Ⅰ

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 16:22

The game of 501 tests your ability to consistently hit high numbers every time you step up to the line. The main thing to remember is to relax and trust your game. It also helps to memorize all of the tungsten dart sequences for your out numbers. Here are some tips that can teach you advanced strategies for 501 tungsten darts.

Find your hot number. Don’t ignore numbers on the board just because they aren’t the highest on the board. If you’re hot on 18s, run with them. A good general rule of thumb is to hit a total of 60 points or better per round. Four 18s will get the job done. Remember that this is a numbers game – go with what you feel comfortable with and hit a lot of them.

Ignore your opponent's throws. It sounds crazy, but there is very little gained from knowing he/she just threw a ton-80 or an eight. A lot of people let this affect their game in a bad way. In 501 the dartboard is your competitor. Beat it by consistently hitting your numbers. There is one exception to this rule. If you thrive on adversity then knowing your opponent's score could pump you up to throw better.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coarse Scheelite Tungsten Ore Processing Plant in Africa

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 16:10

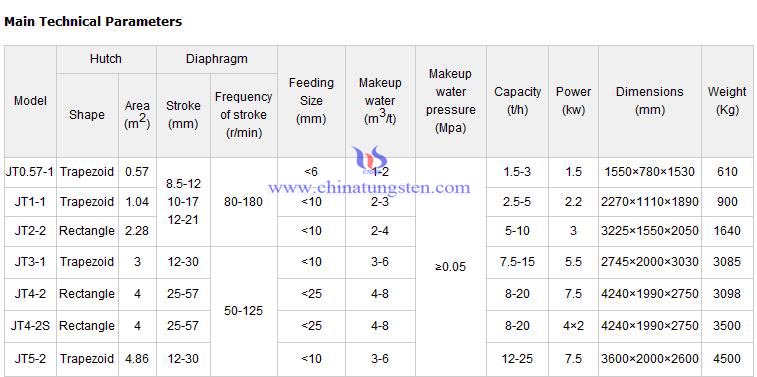

Advantages and Characteristics

1 High capacity

2 High concentration ratio and high recovery

3 Easy to install, operate and maintain

4 The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

5 Saving water 30-40% than ordinary jig

6 The pulsation speed very easy adjusted by regulator

7 Can achieve a good result in processing such as placer gold, tungsten,iron, tin, hematite, copper, tantalum-niobium, titanium, manganese, barite, zirconium, chrome and gemstone etc.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Descriptions of Coarse Scheelite Tungsten Ore Processing Plant in Africa-II

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 16:06

However, there are many scheelite tungsten mines with big coarse scheelite inlay size even over 5mm in Africa, and here gravity separation can be used to recover the coarse scheelite granules and this lowers the scheelite loss due to crushing or milling. If floatation separation is used directly for this coarse scheelite ore, the recovery rate will be lowered and this will be not so good as gravity separation. Here the scheelite tungsten gravity separator is scheelite jig separator. Gravity separation of jigging separator-shaking table is very common to use in the real operation.

Well tech company Saw-tooth Wave Jig is a new type of energy saving and high efficient gravity separation equipment and developed based on the traditional Sine Wave Jig. The difference between Saw-tooth Wave Jig and Sine Wave Jig is that the pulsation curve for jigging is saw-tooth wave shape, with speedy upward flow and slow downward flow. Bed layer is elevated integrally and slowly dropped with a long effective loose time, allowing significant increase of handling capacity for unit screen surface, decrease of lower limit of grain size recovery and large save of make-up water for under size fraction.

In practice, contrast of Saw-tooth Wave Jig and Sine Wave Jig shows up raises of recovery of Saw-tooth Wave Jig: Sn:3.01%, W:5.5%, Pb:1.63%, Zn:2.04%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Description of Coarse Scheelite Tungsten Ore Processing Plant in Africa-I

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 16:04

How to scheelite ore dressing process? And what grade of tungsten can be processed?

For scheelite tungsten ore, floatation separation is used very commonly due to its great floatability. Rough floatation separation and fine selection has been included in the floatation separation of scheelite. Rough floatation separation is to remove the waste to the largest extent with a good recovery while the fine selection is the key to get high grade scheelite tungsten concentrate.

The sulfide ore is usually mixed in the white ore bed with the molybdenite especially common. During the scheelite beneficiation, sulfide ore will be beneficiated by floatation separation, and then the Scheelite will be floated then. The floatation of Scheelite is done in alkaline medium. Na2CO3 and NaOH will be used to improve the Ph of the pulp to 9-10.5. Sodium silicate, quebracho juice, tannin, kinds of phosphate will work as inhibitor. oleic acid, sodium oleate, tall oil, oxidized paraffin wax soap will be used as collector with its own frothing capacity while most of them needs no blowing agent when working.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Processing of Low Grade Tungsten Ore Concentrates by Hydrometallurgical Route

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 15:38

Tungsten, because of its high strength and high melting point occupies a prime position amongst metals. With depletion of high grade resources considerable R and D work is still being carried out in tungsten producing countries around the world for the processing of low grade and secondary resources. The paper gives a brief review of the hydrometallurgical processes developed to recover tungsten from low grade concentrates.

The R and D work carried out on purification and recovery of tungsten as tungstic oxide/ammonium paratungstate (APT) from a number of off-grade products such as table concentrate (WO3=66%, SiO2=2·2%, S=1·8%), middlings (18–20% WO3, and 28–30% S) and jig concentrate (4·6% WO3) are discussed in this paper. It has been found that more than 75% of silica and 90% of sulphur could be removed from the table concentrate by curing with hydrofluoric acid and subsequent roasting of the desilicated product at 650°C. In the case of middlings, it was possible to recover over 90% of tungsten as tungstic oxide by an oxidative roast followed by pressure leaching with soda.

A detailed study on the low grade jig concentrate to recover tungsten as APT, showed that over 90% extraction was possible by adopting the pressure leaching-solvent extraction route. Effect of parameters such as soda concentration, time, temperature and pressure during leaching; as well as extraction and stripping behaviour of tungsten from leach solution at different pH and aqueous to organic ratio during solvent extraction with Alamine-336, were studied and a flow-sheet was developed for processing of jig concentrate analysing 4·6% WO3.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Beneficiation Process of Tungsten Ore-2

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 15:33

Tungsten Ore Beneficiation Process

Tungsten ore beneficiation processes and other mineral processing operations with tungsten in the ore require accurate mass flow measurements to properly balance the grinding and separation circuits as well as to determine the true throughput impact of circuit changes. Determination of the mass flow requires an accurate measurement of the volumetric flow rate and the specific gravity of the slurry.

Tungsten Ore Beneficiation Production Line Wholesalers

DOUBLE Machinery manufactures a full line of crushing equipment for use in processing tungsten ore beneficiation plant and tungsten ore dressing plant. Stationary, portable, mobile crushing plant is available to meet the material reduction requirements.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Beneficiation Process of Tungsten Ore-1

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 15:31

Tungsten ores and concentrates are converted into the following intermediate products: APT, tungsten acid, sodium tungstate, tungsten metal powder, ferrotungsten, and tungsten carbide powder. Most of the APT is reduced to tungsten metal powder, which then may be processed into tungsten carbide powder or ferrotungsten.” End uses of tungsten include metal working, mining, and construction machinery and equipment, 74%; electrical and electronic machinery and equipment and transportation, 10%; lamps and lighting, 9%; chemicals, 4%; and other, 3%.

Beneficiation process of tungsten ore

Tungsten Ore Process

Tungsten ore is found in three forms: WS2 (rare), CaW04 (Sweden) and (FeMn)W04. We need the Mn just as much as the W, so don’t waste it. The first process is gleaned from the 1958 “Rare Metals Handbook”. First, the ore must be reduced to face powder size. We today would crush and grind, but that equipment and the alloys to build it, just will not be available for a long time.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Beneficiation Process-II

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 August 2015 15:24

The tungsten ore industry requirements as well as the role: The tungsten mineral industry requirements (or mineral the industrial requirement), including the deposit boundary taste (WO3%), industrial grade (WO3%), mining excluding thickness (m) Thickness (m) and Stone.

Tungsten deposits associated useful components usually tin, molybdenum, bismuth, copper, lead, zinc, antimony, gold, silver, cobalt, beryllium, lithium, niobium, tantalum, rare earth, sulfur, phosphorus, arsenic, a piezoelectric crystal, melting crystals and fluorite. , Sulfur, phosphorus, arsenic, molybdenum, calcium, manganese, copper, tin, silicon, iron, antimony, bismuth, lead, zinc smelting process of tungsten and tungsten products harmful impurities, various types of tungsten concentrate products containing these harmful impurities, the state has developed the industry standard GB2825-81, tungsten ore (18), these harmful component, enriched After select technical approach, comprehensive recovery, become victims for the benefit of turning waste into treasure and comprehensive utilization.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com