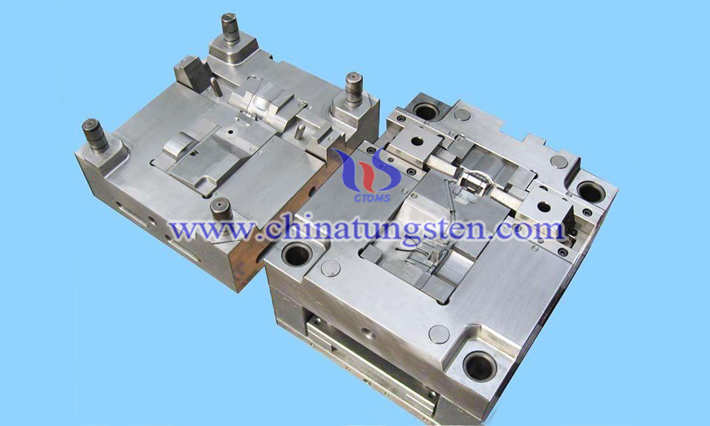

Injection Mold of Tungsten Disulfide

- Details

- Category: Tungsten Information

- Published on Monday, 21 October 2019 13:35

As tungsten disulfide has good lubricating performance and excellent high temperature resistance, it can be coated on injection mold to improve its lubricating performance and prolong its service life. In addition, the coating thickness of tungsten disulfide is very small.

Tungsten Disulfide Applied in Mars Probe

- Details

- Category: Tungsten Information

- Published on Monday, 21 October 2019 11:52

Lubricious tungsten disulfide can be used under complex working conditions such as high temperature, high pressure and vacuum. Therefore, it can be applied in lubrication of Mars probe parts to ensure their long-term work.

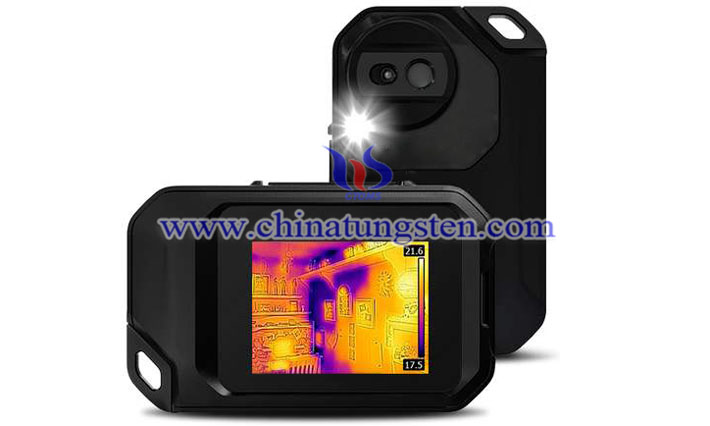

Tungsten Disulfide Used in Infrared Thermal Imager

- Details

- Category: Tungsten Information

- Published on Monday, 21 October 2019 11:49

Tungsten disulfide can be used in the lubrication of lens tube to prolong its service life. Lens tube is the main rotating part of infrared thermal imager. It is important to provide stable lubrication for the lens tube as the working environment of infrared thermal imager is complex.

Tungsten Disulfide Coating Thickness Measured by Magnetic Thickness Gauge (II)

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2019 20:18

Coating thickness of tungsten disulfide can be measured by a main type of magnetic thickness gauge, magnetic or electromagnetic induction thickness gauge. Tungsten disulfide coating with diamagnetism is usually applied to protect the metal surfaces.

Tungsten Disulfide Coating Thickness Measured by Magnetic Thickness Gauge (I)

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2019 20:11

As tungsten disulfide has diamagnetism, its coating thickness can be successfully measured by magnetic stretching thickness gauge. And magnetic stretching thickness gauge is a main kind of magnetic thickness gauge.

Tungsten Disulfide Coating Thickness

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2019 20:04

Tungsten disulfide coating is a high quality solid lubricating material, which is related to its coating thickness. Tungsten disulfide coating with thin thickness can be used to treat the metal surfaces and prevent them from harm, having great application value in many fields.

What is Tungsten Disulfide Coating?

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2019 19:55

Tungsten disulfide coating is a continuous solid film coated by tungsten disulfide once. It is formed by spaying or blushing film-forming agent on the friction surface. And the film-forming agent is made from tungsten disulfide powder and organic binder or inorganic binder. Tungsten disulfide coating is regarded as the most promising solid lubrication coating.

Tungsten Disulfide/Tungsten Trioxide Monohydrate Heterojunction

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2019 19:45

Heterojunction of tungsten disulfide and tungsten trioxide monohydrate is a transverse heterojunction formed by tungsten disulfide and tungsten trioxide monohydrate with covalent bonds. It has great potential application value in the field of photocatalytic semiconductor nanocomposites.

Tungsten Disulfide Film Prepared by Sulfurization

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2019 19:41

Tungsten disulfide film can be successfully prepared by the sulfurization of tungsten trioxide film, which is deposited on the substrate. As the method has attracted the attention of people, the performance of tungsten disulfide film prepared is being studied by more and more people.

How to Prepare Tungsten Disulfide/Titanium Silicide Composite Catalyst?

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2019 19:36

Tungsten disulfide/titanium silicide composite catalyst has broad application prospects in water-splitting for hydrogen production. It can be prepared by raw materials of ammonium tetrathiotungstate and titanium silicide. And ultrasonic-electrodepositing method and calcination method are applied in the preparation process.

sales@chinatungsten.com

sales@chinatungsten.com