ZnO-WO3 Composite Film

- Details

- Category: Tungsten Information

- Published on Monday, 23 March 2020 19:51

ZnO-WO3 composite film is a composite thin film inlaid with ZnO nanocrystals. More specifically, the composite film adopts amorphous WO3 as a matrix, and ZnO nanocrystals are uniformly distributed in the amorphous tungsten oxide. Some experts have prepared ZnO-WO3 composite film on aluminum foil by sol-gel method, and its modification has been carried out with activated carbon. Taking methyl orange aqueous as simulated organic pollutant, photocatalytic degradation performance of ZnO-WO3 films is studied.

Yellow Tungsten Oxide Applied for Cement-based Absorbing Material

- Details

- Category: Tungsten Information

- Published on Monday, 23 March 2020 19:50

Yellow tungsten oxide is applied as a cement-based absorbing material because it has certain shielding properties against gamma rays. Well, what is the shielding performance of yellow tungsten oxide against gamma rays? Some experts used tungsten oxide powder as a fine aggregate to prepare a sample of φ10.5cm x 6cm cylindrical cement-based materials, and tested the shielding performance of the sample against gamma rays through an experimental system composed of a PTW UNDOS standard meter and ~ (60) Co, ~ (137) Cs sources.

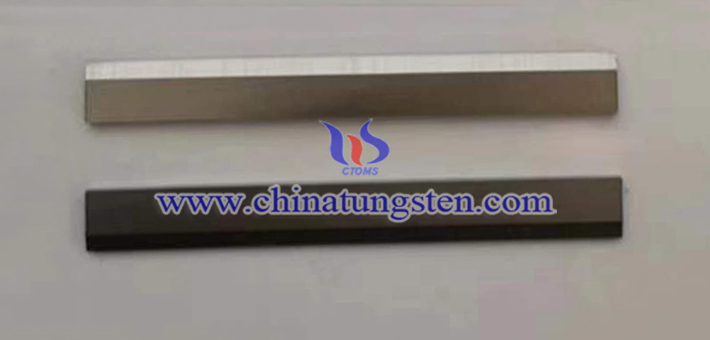

Tungsten Carbide Cutter Applied for Mask Making Machine

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 20:24

Tungsten carbide cutter is specially designed with an upper cutter and a lower cutter for applying to mask making machine. According to the experts, the quality of tungsten carbide upper and lower cutters is affected by many factors. Wherein, the change of various process parameters during the sintering process has a great impact on the quality of the cutter. And the performance of cutter is determined by the materials such as the binder and the base material. Besides, the cleanliness of the particle surface and particle size also affect cutter’s performance.

Tungsten Carbide Cutter Applied for Mask Machine

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 20:23

Tungsten carbide cutter has the properties of high hardness, high strength, high toughness and high heat resistance (thermal stability), so it is suitable for applying to mask machine to produce cup-type masks, non-woven flat masks, and N95 masks, etc.

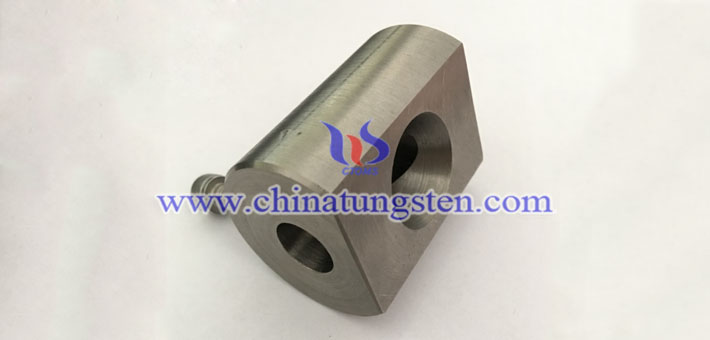

Tungsten Carbide Scraper Applied for Mask Machine

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 20:22

Tungsten carbide scraper is an important part of mask machine to fabricate surgical masks, N95 masks and other protective masks. Such a high-precision scraper can effectively clean the scraps generated by the mask machine during cutting process without polluting the environment.

Tungsten Carbide Blade Applied for Mask Machine

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 20:19

Tungsten carbide blade is widely applied in mask machine such as cup mask machine, non-woven flat mask machine, N95 mask machine, 3M9001/ 9002 folding mask machine, duckbill mask machine, and stereo dust mask machine, etc.

Medical Tungsten Alloy Radiation Shielding Door

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 09:19

Medical tungsten alloy radiation shielding door is a high-density tungsten alloy radiation shielding door. It has been reported that the density of a raw material will affect the property of the prepared radiation shielding parts. Higher density means better ray absorption and radiation shielding ability.

Tungsten Alloy Collimator Applied for X Ray Detector

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 09:18

Tungsten alloy collimator has high density and excellent X-ray absorption ability so that it can be used in X ray detector, thereby absorbing scattered radiation and exerting precise alignment performance for obtaining high-resolution images.

Medical Tungsten Alloy Radiation Shield

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 09:16

Medical tungsten alloy radiation shield refers to a shielding part made of high-density tungsten-based alloy with the composition of W-Ni-Fe, W-Ni-Cu or W-Ni-Cu-Fe. During the generation of X-ray radiation in medical treatment, the tungsten alloy radiation shield is an appropriate radiation dose-reducing measure to minimize risk to the patient and the medical team.

Tungsten Alloy Isotope Container

- Details

- Category: Tungsten Information

- Published on Friday, 20 March 2020 08:55

Tungsten alloy isotope container is a specially designed shielded transport container for radioactive sources. Also, such a container can also serve as a storage or exposure container for the radioactive sources. In nuclear medicine, it is necessary to store the radioactive sources safely, so vials of radiopharmaceuticals are held in tungsten alloy radiation shielding - tungsten alloy isotope container while the dose is drawn up into a syringe ready for treatment.

sales@chinatungsten.com

sales@chinatungsten.com