Preparation Method of Ultrafine Grain Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 April 2021 22:47

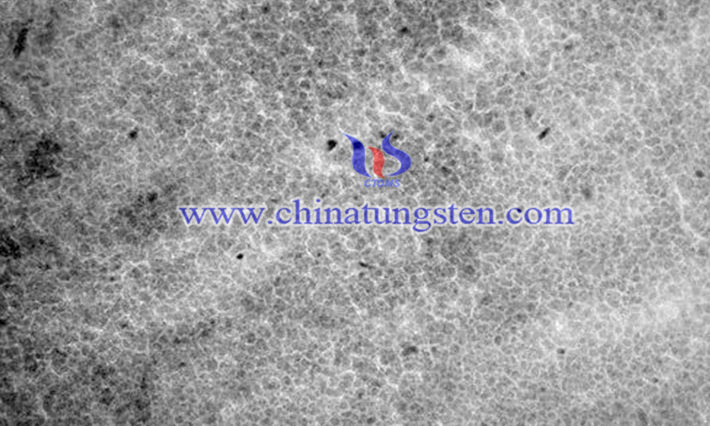

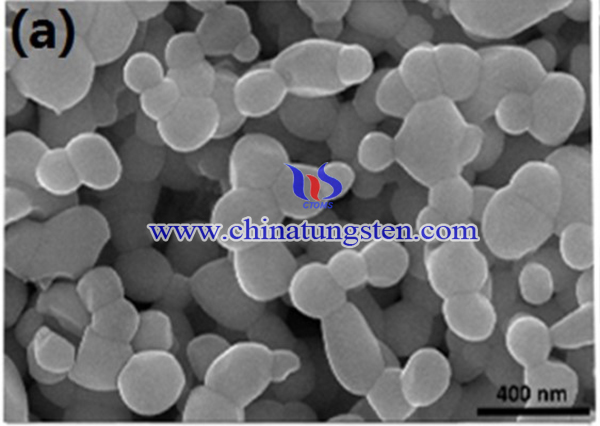

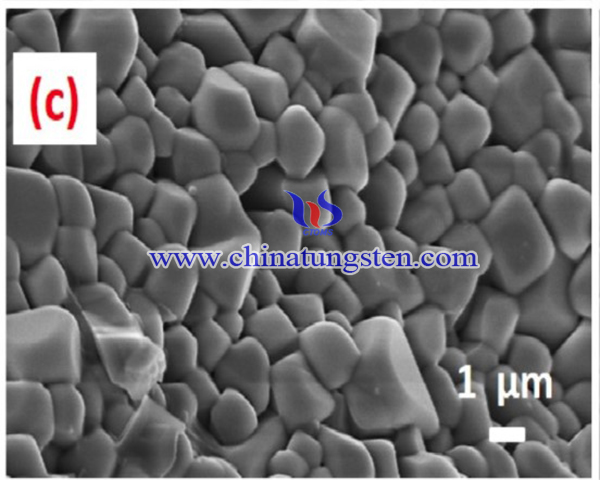

Ultrafine grain tungsten carbide is a kind of cemented carbide made up of tungsten carbide (or other carbide) powder less than 0.3µm and cobalt bonded phase. With the decrease of WC grain size, the toughness and hardness of the cemented carbide can be improved. Because the WC grains become smaller, the high dispersion of the cobalt bonded phase is increased, and the WC grains are more evenly dispersed among the cobalt bonded phases. The hardness at high temperature and compressive strength at room temperature also increase correspondingly. There are many methods to prepare ultrafine grain tungsten carbide using raw WC powder, among which the preparation methods using tungsten oxide as raw materials mainly include carbothermic reduction method and hydrogen reduction method.

Preparation Method of Nano Molybdenum Disulfide

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 April 2021 20:49

As the excellent property of nano molybdenum disulfide, its preparation method has attracted great attention at home and abroad. Currently the chemical synthesis methods of nano molybdenum disulfide mainly include: chemical reduction, chemical decomposition, chemical oxidation, electrochemical, surfactant assisted, hydrothermal and solvothermal synthesis method, natural mineral purification and physical method, etc.

Influence of Copper Content on Tungsten Copper Density

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 April 2021 14:18

The copper content of the tungsten copper alloy produced by the pressureless sintering process has a concentration gradient change in the product, which will influence on tungsten copper density directly.

Preparation of K-doped Tungsten Alloys Using APT

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 April 2021 06:25

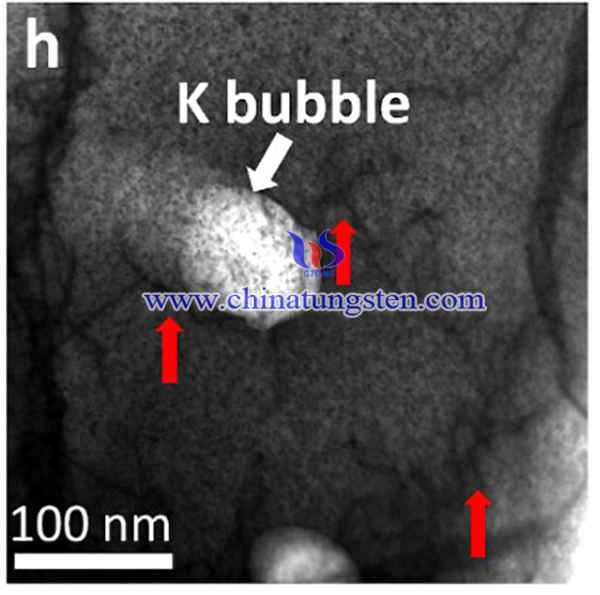

To improve the strength of metals, dispersion strengthening has been developed as an effective method for years. After decades of development, various dispersion particles were applied, such as refractory oxides, carbides, and nitrides.

Sol-Gel Synthesis of CeWTi Catalysts via Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 April 2021 06:13

The environmental issues and health effects by nitrogen oxides (NOx) had caught more attentions in the past decade. The main source of NOx resulting from human activities is the burning of fossil fuels (coal, gas and oil) especially gasoline used in cars. V2O5-WO3-TiO2 is the most common catalysts applied in industrial field for NOx reduction. Unfortunately, the toxicity of V2O5 limits the applications in some fields. Ce-based (Cerium) catalysts, which exhibit remarkable redox properties and high oxygen storage capacity, have attracted much attention in the NH3-SCR reaction.

Crystallization of Ammonium Paratungstate from Ammonium Tungstate Solution

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 April 2021 18:21

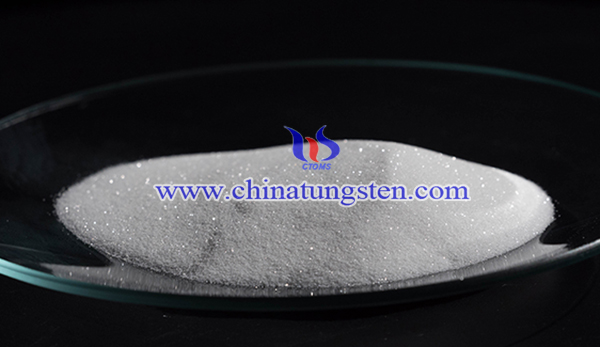

The crystallization of ammonium paratungstate (APT) from aqueous ammonium tungstate solutions is a key unit operation in the current production of tungsten powder. The crystal size, crystal size distribution, and degree of agglomeration of ammonium paratungstate tetrahydrate, (NH4)10[H2W12042] ·4H20, (APT·4H20) are all likely to be of importance for its processing to tungsten powder. Both batch and continuous crystallizers are used in industrial practice.

Tungsten Alloys with High Thermal Shock Resistance via Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 April 2021 17:49

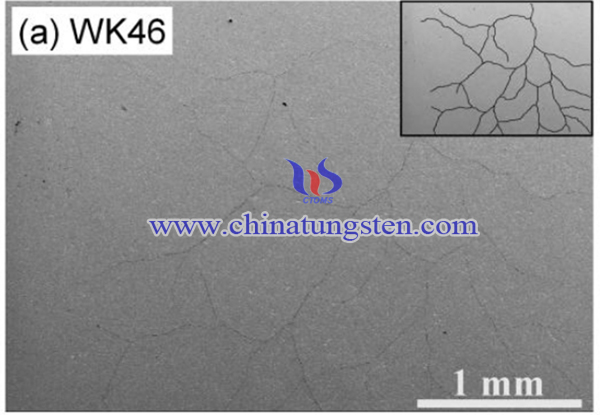

Tungsten (W) alloys has been applied in high temperature resistant materials for decades due to its amazing thermal resistance and toughness. W alloys have been applied in plasma-facing materials, solid target in spallation neutron source, electrical contacts, and fuel elements in rockets, etc. These applications have a requirement on higher mechanical properties and higher temperature stability.

W-Bivo4 Gas Sensing Material Using Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 April 2021 17:33

Trimethylamine is a hazardous volatile organic compound that originates from spoiled fishes and sea creatures and has negative effects on air quality and human health. The gas sensing materials based on metal oxide semiconductors have attracted considerable attention due to the advantages on high sensitivity, low-cost synthesis route and compatible with micro-electronic manufacturing technology.

Red Phosphors Fabricated via Ammonium Paratungstate by Sol-Gel Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 April 2021 17:19

White light-emitting diodes (LEDs) are considered as next generation lighting devices and gained promising attention because of their attractive advantages such as small size, long reliability, low energy consumption, high luminescent efficiency and eco-friendly nature over the conventional incandescent and fluorescent lamps. A technique which combines UV LED and tri-color (Red, Green, Blue) phosphors is a solution to achieve a better display. The combination produces bright white light with high color rendering index and low correlated color temperature. unfortunately, the performance of red phosphor is much weaker than the performance of blue and green phosphors.

Preparation of Tungsten Trioxide Solid Acids Using Ammonium Paratungstate as Tungsten Source

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 April 2021 16:42

Solid acid catalysts (SACs) have a widely and valuable industrial applications such as petroleum, biodiesel, and chemical industries. SACS are considered as the most important categories of catalysts that serve the petroleum industry. Thus, SACs promote environmentally benign heterogeneous catalysts that assist wide industrial applications.

sales@chinatungsten.com

sales@chinatungsten.com