Preparation Method of Ultrafine Grain Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 April 2021 22:47

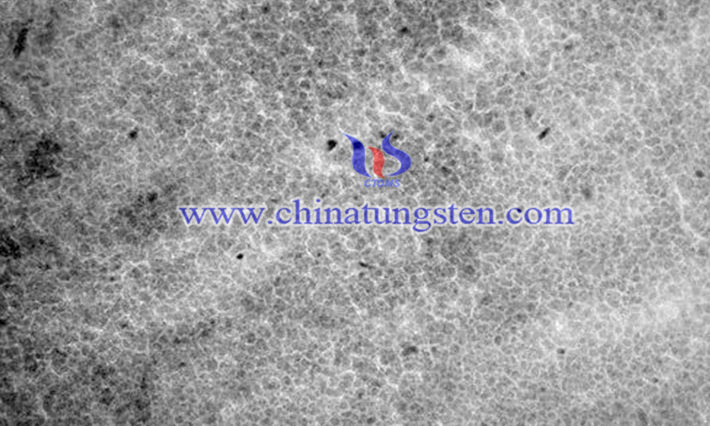

Ultrafine grain tungsten carbide is a kind of cemented carbide made up of tungsten carbide (or other carbide) powder less than 0.3µm and cobalt bonded phase. With the decrease of WC grain size, the toughness and hardness of the cemented carbide can be improved. Because the WC grains become smaller, the high dispersion of the cobalt bonded phase is increased, and the WC grains are more evenly dispersed among the cobalt bonded phases. The hardness at high temperature and compressive strength at room temperature also increase correspondingly. There are many methods to prepare ultrafine grain tungsten carbide using raw WC powder, among which the preparation methods using tungsten oxide as raw materials mainly include carbothermic reduction method and hydrogen reduction method.

1.0 Carbothermal reduction method

It is a type of new preparation method that can reduce production cost and particle size, improve product purity and conductivity. Carbothermal reduction method has been widely used abroad, the advantage of this method is that the particle size of tungsten powder can be well controlled during the reduction process, and ultrafine tungsten carbide below 0.1µm can be produced, but the equipment is high in cost. Currently the better way at home is to prepare nano tungsten powder using purple tungsten (wo2.72) as raw material through hydrogen reduction, and then add carbon black for high-temperature carbonization to produce ultra-fine tungsten carbide. The overall quality of tungsten carbide produced using this technology is stable, but there are also many disadvantages such as powder agglomeration and easy to grow up during sintering. In foreign countries, the technology of preparing ultrafine WC using blue tungsten with high specific surface area as raw material has been industrialized, but it is still in the test stage.

2.0 Hydrogen reduction method

The method is to reduce metal oxides using hydrogen at high temperature to produce metal. It is widely used in the production of tungsten, molybdenum, cobalt, iron and other metal powders, germanium and silicon. Compared with other methods such as reduction method, zinc reduction method etc., the product property is easier to control and the purity is higher.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com