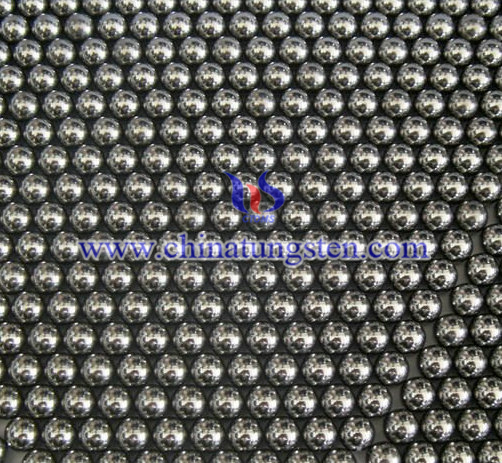

Military Tungsten Alloy Ball for F1 Grenade

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:55

Military tungsten alloy ball is made of tungsten alloy. It is small but very dense. Military tungsten alloy has high density, great hardness and non-toxicity. The fragment of F1 grenade is made of military tungsten alloy ball.

The F1 grenade is manufactured by Thales Australia and is used by the Australian Defence Force replacing the M26 grenade. The F1 is a high explosive, anti-personnel grenade with a lethal radius of 6 metres (6.6 yd), casualty radius of 15 metres (16 yd) and a safety radius of 30 metres (33 yd). The grenade weighs 375g and contains over 4000 2.4 mm steel ball fragments arranged to achieve uniform distribution of lethal fragments through 360° upon functioning. It has a fuse time of 4.5 to 5.5 seconds. Thales Australia also manufactures an F3 practice grenade, being a non-fragmentation replica of the F1 used for training, incorporates a high impact aluminium die cast body and hazard band with a distinctive appearance. The F3 practice hand grenade has a replaceable pyrotechnic fuze that displays an audible output and a distinct cloud of white smoke visible to 200 metres (220 yd) to indicate functioning.

With the high density and hardness of military tungsten alloy ball, F1 grenade has great destruction in battlefield.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

2013 World Darts Championship Quarterfinals Taylor vs Hamilton

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:51

2013 World Darts Championship quarterfinals Taylor vs Hamilton race videos.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

2013PDC World Darts Championship Half Finals Taylor vs Van Barneveld

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:48

2013PDC World Darts Championship half finals Taylor vs Van Barneveld video game, Taylor win.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Ball for M26 Grenade

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:34

Military tungsten alloy ball is made of tungsten alloy. It is small but very dense. Military tungsten alloy has high density, great hardness and non-toxicity. The fragment of M26 grenade is made of military tungsten alloy ball.

The M26 grenade is a fragmentation hand grenade made by the United States.

The M26 grenade is a fragmentation grenade developed by the United States military. It entered service around 1952 and was used in combat during the Korean War. Its distinct lemon shape led it to being nicknamed the "lemon grenade".

Fragmentation is enhanced by a special pre-notched fragmentation coil that lies along the inside of the grenade's body. This coil had a circular cross-section in the M26 grenade and an improved square cross-section in the M26A1 and later designs.

Military Tungsten Alloy Ball for MK3 Grenade

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:27

Military tungsten alloy ball is made of tungsten alloy. It is small but very dense. Military tungsten alloy has high density, great hardness and non-toxicity. The fragment of MK3 grenade is made of military tungsten alloy ball.

The MK3 offensive hand grenade is a cylindrical concussion grenade designed to produce casualties during close combat while minimizing danger to friendly personnel. The grenade is also used for concussion effects in enclosed areas, for blasting, or for demolition tasks. The shock waves (overpressure) produced by this grenade when used in enclosed areas are greater than those produced by the fragmentation grenade. It is, therefore, very effective against enemy soldiers located in bunkers, buildings, and fortified areas.

With the high density and hardness of military tungsten alloy ball, MK3 grenade has great destruction in battlefield.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Replace Tungsten Dart Tip Tutorial Gangbiao

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:22

The replacement process demonstrates tungsten Gangbiao.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Ball for M67 grenade

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:12

Military tungsten alloy ball is made of tungsten alloy. It is small but very dense. Military tungsten alloy has high density, great hardness and non-toxicity. The fragment of M67 grenade is made of military tungsten alloy ball.

The M67 grenade is a fragmentation hand grenade used by the United States military. The M67 is a replacement for the M26-series grenades used during the Korean and Vietnam Wars, and the older Mk 2 "pineapple" grenade used since World War II.

The M67 grenade has a spherical steel body that contains 6.5 ounces of composition B explosive. The M213 fuse is specifically designed for use with the M67 fragmentation grenade. The M67 grenade weighs 14 ounces in total and has a safety clip to prevent the pin on the grenade from being pulled accidentally. The pin prevents the lever, or "spoon" on the grenade from flipping off and arming the fuse on the grenade.

With the high density and hardness of military tungsten alloy ball, M67 grenade has great destruction in battlefield.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military Tungsten Alloy Ball for Hand Grenade

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 10:02

Military tungsten alloy ball is made of tungsten alloy. It is small but very dense. Military tungsten alloy has high density, great hardness and non-toxicity, which means ideal material for hand grenade.

A hand grenade is any small bomb that can be thrown by hand. A variety of types of hand grenades exist, the most common being explosive grenades designed to detonate after impact or after a set amount of time.

Hand grenade can used to kill persons. Anti-personnel hand grenades are weapons that are designed to disperse lethal fragments upon detonation.

With the high density and hardness of military tungsten alloy ball, hand grenade has significant performance in battlefield.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Identify Gold Plated Jewelry

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 09:56

Jewelry with any gold content has become of interest since the price of gold has increased. Gold plated jewelry is sometimes difficult to identify, since there are three basic groups of gold jewelry to learn.

Gold jewelry is 9k gold or higher, and may or may not be marked, depending on whether it is made in a studio, or in a large manufacturing plant.

Gold filled jewelry was made in the 1950s and 1960s primarily, and it has more gold content than gold plated jewelry, and is often marked with 1/20 12k gf or similar marks.

Gold plated jewelry has a layer of gold on the surface, and those who test gold with an acid test kit often find that gold plated jewelry will test gold, but is not.

Know the difference in these three categories when purchasing gold jewelry. There is a difference in value.

Identify gold plated jewelry by content marks.

Find identification marks on the jewelry. HGE is a common marking for gold electroplate. This is a gold plated jewelry. So is RGP or rolled gold plate, a mark often seen on vintage jewelry. Any gold overlay is gold plated jewelry, including vermeil (pronounced ver-may). Vermeil is gold plating over a sterling silver base, and this is fine jewelry, although the gold plating may wear over time.

2.Look for costume jewelry maker marks.

Know the costume jewelry maker names and look for these. Names like Napier, Robert, Kramer, Monet are not likely to be gold plated. Costume jewelry is often a base metal with a metallic coating that is not 9k gold or above, and probably is not gold at all. This is called goldtone jewelry.

3.Look at the corners and edges.

Check the jewelry with a loupe to see if there are worn areas on the corners or edges. This will frequently identify gold plated jewelry, because the top layer wears on the corners and edges, and reveals a different color or type of metal under that surface.

4.Test with an electronic gold tester.

Test questionable items with an electronic gold tester if they are not marked by content or maker. This will accurately identify gold plated jewelry, and the acid test kits will not. Acid test kits recommend scratching the jewelry to get past the surface layer, but good gold plated jewelry often tests gold although it is not. Identify gold plated jewelry before you buy--since it has lesser value than gold filled or karat gold jewelry.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

ZTZ-99 May Use New Tungsten Alloy Armor Piercing

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 09:08

Russian media infers that Chinese newly ZTZ-99 has been equipped with new powerful tungsten alloy armor piercing which can penetrate the armor whose thickness is 850mm.

It is said that China can develop its main battle tank without borrowing design from abroad any more. Russian military experts consider that ZTZ-99 is quite similar with T-72M which was developed by the Soviet Union. ZTZ-99 is much better than T-72M. 125mm smoothbore gun equipped on ZTZ-99 has similarities with 2A46 smoothbore gun. But the technique of tungsten alloy armor piercing comes from Israel. China had ever got M711 armor piercing from Israel before. The diameter ratio of M711 is 20:1. Initial velocity is 1700m/s. It can penetrate armor whose thickness is 600mm.

The technique of tungsten alloy armor piercing in China has been improved a lot. China develops a new tungsten alloy armor piercing based on M711. The diameter ratio is increased to 30:1 and initial velocity is increase to 1700m/s. Penetration is increased from 600mm to 850mm.

Using new tungsten alloy armor piercing, power of smoothbore gun adopted by ZTZ-99 is higher than 2A46 by 45%, higher than RH-120 which is adopted by Leopard II and M1A1 by 30%. ZTZ-99 has great threaten to most of active service tanks including advanced main battle tanks serving in U.S. Army or Russian Army.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com