Micro-Adjustable Bucking Bar Anvil

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 08:52

Disclosed is a hand held micro-adjustable bucking bar anvil having an adjustable threaded spindle for positioning the anvil face to the correct height above the surface of the sheet metal, for shaping new rivet heads to the proper diameter, height, and shape meeting the manufacturer's specifications for riveting sheets of metal together as the riveting process is completed. A further disclosure of this present invention is incorporating a threaded spindle having positioning feet. The positioning feet will maintain the rivet head tolerances as the self-leveling feet reaches the working surface; the feet will align the micro-adjustable bucking bar's horizontal and vertical axis to meet the height, diameter, and shape of the rivet heads. The feet align the bucking bar anvil equally on flat surfaces as well as curved surfaces, while shaping rivet heads. The hand held micro-adjustable bucking bar anvil incorporates a spring-loaded spindle lock for locking the threaded spindle in a desired position on the micro-adjustable bucking bar. This creates a micro-adjustable spindle for easy setting by an inexperienced or experienced bucking bar operator while maintaining the rivet head tolerances to the manufacturing specification.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Bucking Bar Tool

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 08:44

The tool used to form an upset head while using a pneumatic rivet gun is a bucking bar. Bucking bars are made in various shapes, sizes and weights. The weight of the bucking bar must be proportional to the size of the rivet.

To obtain a proper upset head, a good technique to use is shown in Figure 1.17.1. As the gun is firing,press the bucking bar firmly against the forming rivet shank and roll the bar slightly. This rolling action will aid in the formation of a barrel-shaped bucktail. If the bucking bar is too light for the size of rivet and gun, the metal will bend toward the bucktail. If the bucking bar is not held firmly against the rivet shank,the metal will bend away from the gun.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

A Metal Anvil-Bucking Bar

- Details

- Category: Tungsten Information

- Published on Thursday, 17 October 2013 08:40

A bucking bar is basically a metal anvil which is placed against the end of the shank of a rivet. Typically, a flat surface of the bucking bar interfaces a flat end of a rivet shank. The head of the rivet is then “hammered” by a driver, thereby causing the shank to spread against the bucking bar. To produce a properly shaped butt of proper thickness, prior art bucking bars have required a skilled operator. Failure of the operator to hold the bucking bar square against the rivet shank will result in misshaped butts and bad rivet resulting in costly rework. Furthermore, prior art bucking bars are prone to wandering during the spreading operation and occasionally wander off the shank, likewise resulting in a bad rivets and subsequent rework.

Bucking bars are available in a variety of shapes and sizes to accommodate various obstacles which potentially interfere with a spreading operation.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide in Dry and Humid Atmospheres

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 21:05

Oxidation experiments were performed on pure tungsten and hot-pressed tungsten carbide. The chemical state and thickness of the oxide products were determined by ESCA. The oxidation of W and WC in dry atmosphere was performed in oxygen at temperatures ranging from 20 to 500 °C. The oxide formed is WO3. The thickness of the oxide layer increases slowly up to 200 °C, after which the oxide growth is rapid.

The oxidation behaviour of W and WC in humid atmospheres was studied at room temperature in air at relative humidities of 60 and 95%. It was found that the thickness of the oxide layer increases with increased humidity. No formation of hydroxide was observed. Exposing W to water for one week results in a thick layer of WO2, WO3 and hydroxide. In the case of WC no oxide at all was visible after exposure to water. Furthermore, WC is resistant to further oxidation after exposure.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

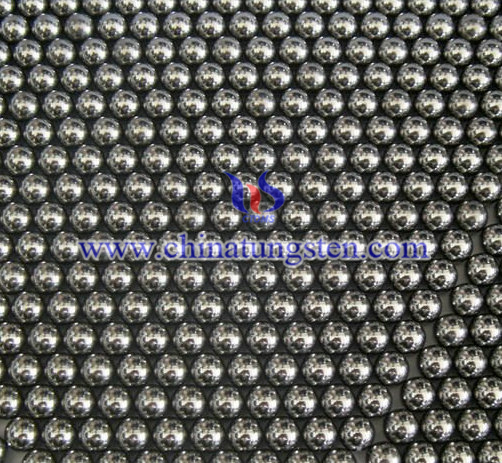

Tungsten Alloy Shot for AL391

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 17:07

Tungsten alloy shot is made of tungsten alloy. High density, great hardness and resistance to high temperature make tungsten alloy to be one of the most sought -after material for shotgun pellets. Density of tungsten alloy shot is about 18g/cm3. Tungsten alloy shot is used as pellet of AL391.

The Beretta AL391 is a semi-automatic shotgun. It is manufactured, marketed, and distributed by Fabbrica d'Armi Pietro Beretta, in Gardone Val Trompia, Italy.

The AL391 is most often used for hunting birds, and for clay target games such as trap and skeet. There are several different models, each with multiple variations. The AL391 is chambered in either 12 gauge or 20 gauge.

Tungsten alloy shot has hgih density and high hardness. For this AL391 has high power in combat.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Shot for Beretta 682

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 17:00

Tungsten alloy shot is made of tungsten alloy. High density, great hardness and resistance to high temperature make tungsten alloy to be one of the most sought -after material for shotgun pellets. Density of tungsten alloy shot is about 18g/cm3. Tungsten alloy shot is used as pellet of Beretta 682.

The Beretta 682 (also known as the S682, 682 Gold and currently 682 Gold E) is a competition grade over-under shotgun. It is manufactured, marketed, and distributed by Fabbrica d'Armi Pietro Beretta, in Gardone Val Trompia, Italy.

The 682 comes in various grades for sporting clays, trap and skeet shooting.

It is distributed in the UK by GMK Ltd, and in the United States by Beretta USA.

Using tungsten alloy shot, Beretta 682 has good performance in hunting competition.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Shot in Benelli Vinci

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 16:53

Tungsten alloy shot is made of tungsten alloy. High density, great hardness and resistance to high temperature make tungsten alloy to be one of the most sought -after material for shotgun pellets. Density of tungsten alloy shot is about 18g/cm3. Tungsten alloy shot is used as pellet of Benelli Vinci.

The Benelli Vinci is a semi-automatic shotgun manufactured and sold by the Benelli company. It uses an inertia-driven system of operation, and contains recoil-reducing features. It also features a modular design consisting of the barrel/receiver module (containing the operating system, barrel, and bolt), the trigger group/forearm module (containing the trigger assembly, safety, shell carrier and magazine), and the buttstock. The shotgun was named after Leonardo da Vinci. It is Benelli's first shotgun to feature an in-line inertia-driven operating system. It is intended primarily for hunting, rather than combat or self-defense; the M3 and M4 shotguns are Benelli's primary contenders in the tactical shotgun market.

Using tungsten alloy shot, Benelli Vinci can be used in anti-terrorism operation.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Shot in Benelli M3

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 16:41

Tungsten alloy shot is made of tungsten alloy. High density, great hardness and resistance to high temperature make tungsten alloy to be one of the most sought -after material for shotgun pellets. Density of tungsten alloy shot is about 18g/cm3. Tungsten alloy shot is used as pellet of Benelli M3.

The Benelli M3 is a dual-mode (both pump-action and semi-automatic) shotgun designed and manufactured by Italian firearms manufacturer Benelli. The M3 holds a maximum of seven rounds and uses the proprietary Benelli semi-automatic system first showcased in the M1. The M3 is notable for allowing the user the choice of semi-automatic or pump-action operation. It is reliable and versatile, and popular with military and police forces as well as civilians.

Using tungsten alloy shot, Benelli M3 can penetrate wall or door and has good performance.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Multiple Composite Tungsten Electrode String Playing Devices Swaging Process Technology Invention and Technical Background

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 16:29

Multiple composite tungsten electrodes swaging process string playing devices invention relates to multi-composite tungsten electrodes swaging string playing equipment and technology , are rare refractory metal materials processing fields. The present invention is swaged through B203 billet after the B202 stage process that uses three tungsten followed in 1450 ~ 1500 ℃ after Φ6.0-Φ5.6 swaging die machining ; followed in 1400 ~ 1450 ℃ after Φ 5.2-Φ4.8 swaging die machining ; followed in 1400 ~ 1450 ℃ after Φ4.4-Φ4.1 swaging die machining . In B201 processing stage after two times , ie tungsten followed in 1400 ~ 1450 ℃ after Φ3.9-Φ3.6 swaging die machining ; followed in 1350 ~ 1400 ℃ after Φ3.3-Φ3.0 swaging die processing, Following the above process can be obtained Φ6-Φ3 diverse composite rare earth tungsten electrode material . The present invention simplifies the production process , improve production efficiency, while economic energy .  < br />

< br />

Multiple composite tungsten electrodes swaging process string playing devices

technical field of the invention

Multiple composite tungsten electrodes swaging string playing equipment and technology , are rare refractory metal materials processing fields.

Multiple composite tungsten electrodes swaging string playing equipment and technology invented technical background

Refractory metals such as tungsten, molybdenum, workability , and thus usually swaging processing methods, namely, rotary hammer rotating at high speed while doing radial reciprocating motion , so that the billet uniform deformation . For tungsten and tungsten alloy processing purposes , often using a single swaging machine head swaging equipment for processing , the original patent ( 200710099090.4 ) , for multiple composite rare earth tungsten electrodes spin -off process that is using this single head the rotary forging machine, multi-composite material of rare earth tungsten electrodes need to go through six stages B202 step, B201 need to go through four stages of process , the process is complicated , labor-intensive , to improve processing efficiency, the two coalition a rotary hammer machine string set is an effective way to play the device , has a similar device is used molybdenum material processing field , and for tungsten , particularly in terms of rare earth doped tungsten material , there are no special equipment such applications , mainly due to the tungsten molybdenum poor machinability performance ratio , especially rare earth doped after rare second phase particles on the material organization of the tungsten material plastic brittle transition temperature changes , and thus for string playing technique , in addition to requirements consistent feed rate In addition, with touch system and the processing temperature is also particularly important .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Shot in Benelli M1

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 16:25

Tungsten alloy shot is made of tungsten alloy. High density, great hardness and resistance to high temperature make tungsten alloy to be one of the most sought -after material for shotgun pellets. Density of tungsten alloy shot is about 18g/cm3. Tungsten alloy shot is used as pellet of Benelli M1.

The Benelli M1 is a semi-automatic shotgun manufactured by Benelli Armi S.P.A.. It is available in several versions for civilian, law enforcement and military use. It features the proprietar y Benelli recoil system, known for its reliability and easy maintenance. The standard model features an aluminum alloy receiver and tubular magazine, and is available with a standard or pistol grip stocks. The M1 Super 90 can be fitted with traditional iron sights, or ghost ring diopter sights. Mounts are available for laser pointers and tactical flashlights. Due to the inertia recoil system, the M1 should use heavier loads to cycle properly but because the action is inertia driven vs. the traditional gas cycling operation it can fire and reliably cycle lighter loads.

y Benelli recoil system, known for its reliability and easy maintenance. The standard model features an aluminum alloy receiver and tubular magazine, and is available with a standard or pistol grip stocks. The M1 Super 90 can be fitted with traditional iron sights, or ghost ring diopter sights. Mounts are available for laser pointers and tactical flashlights. Due to the inertia recoil system, the M1 should use heavier loads to cycle properly but because the action is inertia driven vs. the traditional gas cycling operation it can fire and reliably cycle lighter loads.

Using tungsten alloy shot, Benelli M1 can penetrate wall or door and has good performance.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com