Vacuum Smelting Process for Producing Ferrotungsten-Background

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 17:31

- Written by xinyi

- Hits: 295

Background of the invention

The process as described in the aforementioned U.S. Pat. No. 3,966,459, is directed to a vacuum dissociation of a pelletized molybdenite concentrated feed material at an elevated temperature, producing pellets of relatively pure metallic molybdenum and the process as described in the aforementioned copending continuation-in-part application is directed to the further embodiment of producing ferromolybdenum alloys containing controlled amounts of iron and molybdenum by the vacuum smelting of a pelletized mixture comprised of a molybdenite concentrate and an iron-bearing material at an elevated temperature, producing ferromolybdenum alloy pellets which are eminently suitable for use as an alloying addition agent in steel-making operations and the like. The present continuation-in-part application is directed to still another embodiment of producing ferrotungsten alloys containing controlled amounts of iron and tungsten, which also are suitable for use as an alloying addition agent in iron and steelmaking operations.

Ferrotungsten alloys are produced in accordance with prior art practices by either employing a thermite process or an electric furnace reduction process. Both of these techniques require substantial amounts of labor and energy and are, therefore, somewhat costly. In the thermite process, for example, a tungstic oxide feed material derived from a chemical pretreatment of a tungsten ore concentrate is mixed with reducing agents, such as silicon and/or aluminum, which through an exothermic thermite-type reaction, produces an ingot or button of the ferro-alloy. The ferro-alloy button usually is of a segregated structure and further requires crushing and sizing prior to shipment and use. The slag produced, for economic reasons, is usually subjected to further treatment for recovery of residual metal values and the treated residue is discarded. In addition to the relatively high costs of the reducing agents required in the thermite process, further problems are presented from an environmental standpoint as a result of the disposal of the slag produced and the treatment required of the gases evolved during the exothermic reaction.

The present process overcomes many of the problems and disadvantages associated with prior art techniques for producing ferrotungsten alloys by utilizing a tungsten ore concentrate directly as the starting material without requiring costly chemical pretreatments to extract the tungstic oxide. Carbon is employed as a low-cost reducing agent, eliminating the formation of any slag, whereby a ferrotungsten alloy is obtained which is of a nonsegregated structure and is in the form of pellets, avoiding the necessity of subjecting the ferro-alloy to a crushing operation as in the case of buttons produced by the thermite process.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Use Tungsten Carbide Step Drill Bits

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 16:51

- Written by zhihua

- Hits: 318

Tungsten carbide step drill bits are used to drill metal up to 1/4 of an inch thick. Step drill bits are designed to enlarge a hole as the bit drills through the sheet metal. Each step on the bit is larger in diameter than the step before. Smaller step drill bits are self-starting and no pilot bit is required to start the hole. On larger step drill bits, you need to have a hole pre-drilled that is equal in diameter to the smallest step on the bit.

-Put on appropriate eye protection (safety glasses or goggles).

-Place the tip of the center punch on the metal to be drilled at the location of the desired hole. Hit the blunt end of the center punch with the hammer to leave an indentation (referred to as a center mark). This indentation will provide a place for the drill bit to "catch" so it doesn't drift to the wrong location on the work.

-Secure the self-starting step tungsten drill bit into the chuck of the drill motor. Apply cutting and tapping fluid to the center mark and the step drill drill bit.

-Align the tip of the self-starting step drill bit with the center mark on the metal's surface. Depress the drill's trigger to start drilling the hole. Run the small step drill bit completely through the metal. Apply additional cutting and tapping fluid as necessary to keep the step drill bit cool.

-Release the chuck of the drill motor to remove the small step drill bit. Secure the large step drill bit into the chuck of the drill motor. Insert the small tip of the large step drill bit into the hole you created in the metal. Apply cutting and tapping fluid onto the large tungsten carbide step drill bit and around the hole in the metal.

-Depress the trigger of the drill motor to run the large-diameter step drill bit into the hole. Stop drilling frequently to apply additional cutting and tapping fluid to the drill bit. Stop drilling when the hole has reached the desired diameter.

-Remove the large step drill bit from the drill motor. Clean both step drill bits with a rag to remove metal shavings from the bits. Clean the metal shavings from around the hole that you drilled in the metal. Store the drill bits in a tool box or drill bit container to avoid dropping them or otherwise damaging them.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tipped Hard Steel Die Drills

- Details

- Category: Tungsten Information

- Published on Sunday, 06 September 2015 18:09

- Written by zhihua

- Hits: 260

Carbide tipped hard steel die drills have heavy duty hardened tool steel bodies to provide shock resilient support for the thick, long carbide tip. They have straight flutes and straight shank. The drill body diameter is smaller than tool diameter.

Die drills may be run at speeds from 75 to 100 SFPM. Apply light feed (.001-.003 I.P.R.) with steady pressure.

Carbide tipped die bits are recommended for those occasions when you need to remove a broken bolt, a broken easy out or threaded fastener.

Carbide tipped die bits:

118° point – negative edge (for steels in the range of 50 Rc to 65 Rc)

118° point – positive edge (for cast iron, high temperature alloys and steels up to 50 Rc)

140° Point – negative edge (for steels in the range of 50 Rc to 65 Rc)

140° point – positive edge (for cast iron, high temperature alloys and steels up to 50 Rc)

The above can be used for coring out pre-existing holes.

Carbide tipped die bits are recommended for those occasions when you need to remove a broken bolt, a broken easy out, or threaded fastener. The left hand cutting action assists with backing the object out of the hole, by it’s counter clockwise spin.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

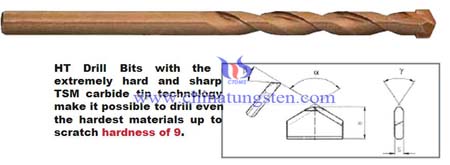

Tungsten Carbide HT Drills Bits Basic Features

- Details

- Category: Tungsten Information

- Published on Sunday, 06 September 2015 18:15

- Written by zhihua

- Hits: 333

Tungsten carbide HT drills bits are specially created for drilling tile, marble, porcelain, ceramics, etc.

Usually HT drill bits have the following dimension types:

DIAMETER TOTAL LENGTH

1/8″ 3″

5/32″ 4″

3/16″ 4″

1/4″ 4″

5/16″ 4-3/4″

3/8″ 4-3/4″

1/2″ 6″

And the below application characteristics:

-Titanium Tungsten TSM carbide. 110° tip angle

-Straight flute entry

-1,120° Low-Stress high temperature brazing.

-Asymmetric spiral flute.

-Highest quality steel.

-Surface hardened

-Use in Rotary mode only!

-Tile: 1200-600 RPM

-Glass: 800-400 RPM (Small diameters use higher rpm, Large diameters use lower RPM)

-Apply high contact pressure if necessary.

-Allow for 20 seconds cooling time between holes for longer bit life

-For use in all materials up to scratch hardness of 9.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Vacuum Smelting Process for Producing Ferrotungsten

- Details

- Category: Tungsten Information

- Published on Sunday, 06 September 2015 18:08

- Written by xinyi

- Hits: 265

Tungsten is an important alloying element in high-speed and other tool steels, and is used to a lesser extent in some stainless and structural steels. Tungsten is often added to steel melts as ferrotungsten, which can contain up to 80% tungsten. World ferrotungsten production is dominated by China, which in 2008 exported 4,835 t (gross weight) of the alloy. Ferrotungsten is relatively expensive, with the prices around $31–44 per kilogram of contained tungsten.

A process for producing ferrotungsten alloys by forming a uniform mixture comprised of a finely-particulated tungsten-containing mineral, such as wolframite, scheelite, ferberite, and/or huebnerite; a supplemental quantity of a particulated iron-bearing material and a controlled amount of a carbonaceous reducing agent which is agglomerated into a plurality of pellets which are heated to an elevated temperature under a controlled vacuum for a period of time sufficient to effect a reduction of the tungstic oxide constituent to the metallic state and volatilization and extraction of the volatile constituents in the pellets, and an alloying of the metallic tungsten with the iron constituent, producing substantially dense sintered ferrotungsten alloy pellets.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com