Sintering Process Effect on Tungsten Copper Electrode Properties II

- Details

- Category: Tungsten Information

- Published on Monday, 16 November 2015 17:27

- Written by xiaobin

- Hits: 292

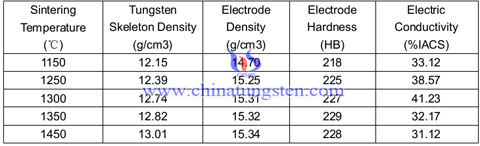

But overall, tungsten copper electrode sintering temperature sintering property performance is more sensitive than the sintering time. The properties of tungsten copper electrode at different sintering temperature for 1h as follow:

As the sintering temperature increases, the density of tungsten skeleton also increases. While to prepare infiltrated tungsten skeleton well, on the one hand requires that tungsten skeleton has a certain hardness and strength, on the other hand requires tungsten skeleton excellent connectivity inside, which is conducive to metallic copper infiltration.

More information about sintering process effect on tungsten copper electrode properties, click here:

http://news.chinatungsten.com/en/tungsten-information/80415-ti-10319

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sintering Process Effect on Tungsten Copper Electrode Properties

- Details

- Category: Tungsten Information

- Published on Monday, 16 November 2015 17:23

- Written by xiaobin

- Hits: 340

For a certain density of compacts, sintering of tungsten skeleton is undoubtedly key processes of manufacturing tungsten copper electrode. High-temperature sintering can remove the impurities easily and ensure the electric conductivity. While the choice of the sintering temperature is mainly consider that the impact of tungsten powder granularity, particle size distribution and pressing density and other factors.

If the temperature is too low, the porosity, the hardness and density of tungsten copper electrode will decrease; If the temperature is too high, the porosity is low, the copper content is relatively reduced, high product density, electrical conductivity, and formability is deteriorated.

Therefore, under normal circumstances would control the sintering temperature range between 1600 ℃ -2200 ℃. The sintering time and the sintering temperature can be achieved relatively matched state by some adjustments to improve the sintering temperature sintering time can be shortened, thereby improving the processing efficiency, and sintering time may be extended to some extent reduce the sintering temperature.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Brad Point Drill Bit Ⅳ

- Details

- Category: Tungsten Information

- Published on Monday, 16 November 2015 16:41

- Written by zhihua

- Hits: 348

In last part we know that tungsten carbide brad point drill bits have two types and the drill bits for soft wood have round outlining spurs while those for hard wood have sharp ones, and we shall not mix them up in different tasks..This part we will explain the two basic types of brad point drill bit.

Another feature of the tungsten carbide brad point drill that could affect its cutting ability is the actual brad or pyramid point in the center. Although the sole purpose of the brad point is to guide the drill through the material and keep it running straight, the shape of the brad point can affect the results. The brad itself does not actually cut the wood. It mainly scrapes and pushes the wood aside. If the base of the brad point is too thick or fat, the drill will be much harder to push especially in hardwoods. A brad that is too thin will allow the drill to cut freely but may break off in the process. It is also very important that the brad is exactly centered at the point of the drill. An off-center brad can cause a drill to cut larger than it actually measures.

We often vary the length of the brad point to achieve different results. A longer brad can be used when a hole needs to be drilled on an angle instead of straight into the wood. Drilling as much as 45 degrees or even 60 degrees from vertical is possible by extending the length of the brad. A shorter than normal brad may be required in the case of a hole that needs to be drilled close to but not through the back of the material.

(To be continued. This article is divided into 5 parts, and this is part 4. For part 3 please refer to http://news.chinatungsten.com/en/tungsten-information/80398-ti-10362; for part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80400-ti-10364)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Brad Point Drill Bit Ⅴ

- Details

- Category: Tungsten Information

- Published on Monday, 16 November 2015 16:43

- Written by zhihua

- Hits: 332

In last part we know that the shape of brad points is important to the cut effects of tungsten carbide brad point drill bits, which requires different features for specific tasks. This part will talk about the other applications of brad point drill bits in other materials.

Tungsten carbide brad point drill bits are ordinarily available in diameters from 3–16 mm (0.12–0.63 in).Brad point drill bits work also well in most plastics, nylon, fiber, fiberglass and many other man made materials. Conventional twist drill bits in a hand drill, where the hole axis is not maintained throughout the operation, have a tendency to smear the edges of the hole through side friction as the drill bit vibrates.

In metal, the tungsten carbide brad point drill bit is confined to drilling only the thinnest and softest sheet metals in a drill press. The bits have an extremely fast cutting tool geometry: no point angle and a large (considering the flat cutting edge) lip angle causes the edges to take a very aggressive cut with relatively little point pressure. This means these bits tend to bind in metal; given a workpiece of sufficient thinness, they have a tendency to punch through and leave the bit's cross-sectional geometry behind.

(The End. This article is divided into 5 parts, and this is part 5. For part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/80399-ti-10363)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Brad Point Drill Bit Ⅲ

- Details

- Category: Tungsten Information

- Published on Monday, 16 November 2015 16:39

- Written by zhihua

- Hits: 306

In last part we know that the tungsten carbide brad point drill bits cut a clean hole by firstly cutting the hole periphery with outlining spurs instead of a straight chisel to avoid pulling off the wood fiber. This part we will explain the two basic types of brad point drill bit.

There are basically two types of tungsten carbide brad point designs we use. One works best in hardwoods and the other works best in softwoods. Tungsten carbide brad point drills that are specifically designed for softwood produce too much heat and are hard to push in hardwoods. Although brad point drills specifically designed to cut hardwood will cut softwood, the aggressive cutting edges have a tendency to lift the weak grains of the softwood resulting in a ragged edge around the opening of the hole.

The difference between the two types of points is in the design of the outlining spurs. The brad point drills that work best in softwood have rounded spurs, which help to hold the grains of the wood down while sheering them off. There is a certain amount of rubbing that occurs between the outlining spur and the wood before it is cut. The outlining spurs on brad point drills for hardwood come to a sharp point and simply cut the stronger grains off clean. No rubbing occurs and therefore no unnecessary heat is produced by the cutting action.

(To be continued. This article is divided into 5 parts, and this is part 3. For part 2 please refer to http://news.chinatungsten.com/en/tungsten-information/80397-ti10361; for part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/80399-ti-10363)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com