Effluent-Free Manufacture of Ammonium Paratungstate (APT) by Recycling the Byproducts

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 17:33

- Written by xinyi

- Hits: 272

Ammonium paratungstate (or APT) is a white crystalline salt of ammonium and tungsten, with the chemical formula (NH4)10(H2W12O42)·4H2O.

Ammonium paratungstate is produced by separating tungsten from its ore. Once the ammonium paratungstate is prepared, it is heated to its decomposition temperature, 600 °C. Left over is WO3, tungsten(VI) oxide. From there, the oxide is heated in an atmosphere of hydrogen, reducing the tungsten to elemental powder, leaving behind water vapor. From there, the tungsten powder can be fused into any number of things, from wire to bars to other shapes.

Within the framework of a review of the fundamental processes applied for the manufacture of ammonium paratungstate (APT) the main byproducts and wastes generated in these processes and their environmental impact are summarized. A subsidiary process based on the electrodialytic recovery of NaOH for the elimination of the salt byproduct, which is generated in the largest quantities, is outlined together with the main aspects to be taken into account for large-scale industrial implementation.The present stage of development and implementation of an APT production line for the processing of typical scrap material from the lighting filament industry is shown, as well as the oxidizing and dissolving process of compact and lumpy tungsten alloy scrap (Cu-W, Fe-Ni-W) and hard metal scrap (Co-WC, Co-WC-Ta(Nb)C-TiC).Several as yet unexploited potentials are sketched which could, from scientific and engineering standpoints, be interesting for the development of more efficient intermediate manufacturing processes for APT and tungsten or process operations for a wide variety of raw materials.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Geometric Characteristics of Tungsten Carbide Drill Bit Ⅴ

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 16:00

- Written by zhihua

- Hits: 319

In last part we know that tungsten carbide drill bits can have various shank length, straight or tapered, and the diameter-to-length ratios range from 1:1 to 1:10 or up. This part we give a table listing tool geometries recommended for some commonly drilled materials.

The best geometry of tungsten carbide drill bits to use depends upon the properties of the material being drilled. The following table lists geometries recommended for some commonly drilled materials.

|

Tool Geometry |

|||

|

Workpiece material |

Point angle |

Helix angle |

Lip relief angle |

|

Aluminum |

90 to 135 |

32 to 48 |

12 to 26 |

|

Brass |

90 to 118 |

0 to 20 |

12 to 26 |

|

Cast iron |

90 to 118 |

24 to 32 |

7 to 20 |

|

Mild steel |

118 to 135 |

24 to 32 |

7 to 24 |

|

Stainless steel |

118 to 135 |

24 to 32 |

7 to 24 |

|

Plastics |

60 to 90 |

0 to 20 |

12 to 26 |

(The end. This article is divided into several parts. Here is part 5. For part 4, please refer to http://news.chinatungsten.com/en/tungsten-information/80549-ti-10419)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Geometric Characteristics of Tungsten Carbide Drill Bit Ⅲ

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 15:55

- Written by zhihua

- Hits: 336

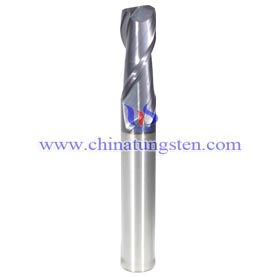

In last part we know that the twist rate of a tungsten carbide drill bit affects removal speed of chips, and the correct point angle varies with working material hardness. This part will go on discussing the geometric characteristics of tungsten carbide drill bits.

3. The lip angle: it determines the amount of support provided to the cutting edge. A greater lip angle will cause the tungsten carbide drill bit to cut more aggressively under the same amount of point pressure as a bit with a smaller lip angle. Both conditions can cause binding, wear, and eventual catastrophic failure of the tool. The proper amount of lip clearance is determined by the point angle. A very acute point angle has more web surface area presented to the work at any one time, requiring an aggressive lip angle, where a flat bit is extremely sensitive to small changes in lip angle due to the small surface area supporting the cutting edges.

4. The length of a bit: it determines how long a hole can be drilled, and also determines the stiffness of the tungsten carbide drill bit and accuracy of the resultant hole. Twist drill bits are available in standard lengths, referred to as stub-length or screw-machine-length (short), the extremely common jobber-length (medium), and taper-length or long-series (long).

(To be continued. This article is divided into several parts. Here is part 3. For part 2, please refer to http://news.chinatungsten.com/en/tungsten-information/80547-ti-10417; for part 4, please refer to http://news.chinatungsten.com/en/tungsten-information/80549-ti-10419)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Geometric Characteristics of Tungsten Carbide Drill Bit Ⅳ

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 15:57

- Written by zhihua

- Hits: 396

In last part we know that the lip angle of a tungsten carbide drill bit changes with the point angle and determines cutting speed, and the drill bits have various lengths according to their purposes. This part will go on discussing the geometric characteristics of tungsten carbide drill bits.

5. The shank: different shapes of shank are used for tungsten carbide drill bits. Some are simply the most appropriate for the chuck used; in other cases particular combinations of shank and chuck give performance advantages, such as allowing higher torque, greater centering accuracy, or efficient hammering action. Most drill bits for consumer use have straight shanks. For heavy duty drilling in industry, bits with tapered shanks are sometimes used.

6. The diameter-to-length ratio of the tungsten carbide drill bit is usually between 1:1 and 1:10. Much higher ratios are possible (e.g., "aircraft-length" twist bits, pressured-oil gun dril bits, etc.), but the higher the ratio, the greater the technical challenge of producing good work.

(To be continued. This article is divided into several parts. Here is part 4. For part 3, please refer to http://news.chinatungsten.com/en/tungsten-information/80548-ti-10418; for part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80550-ti-10420)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Geometric Characteristics of Tungsten Carbide Drill BitⅡ

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 15:52

- Written by zhihua

- Hits: 299

In last part we know that tungsten carbide drill bits are composed of tungsten carbide tips and shanks, either brazed or solid, used for cutting holes. This part will discuss the geometric characteristics of tungsten carbide drill bits.

Drill bit geometry has several characteristics:

1. The spiral (or rate of twist): the spiral in the tungsten carbide drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spindle speeds, where removal of a large volume of swarf is required. Low spiral (low twist rate or "elongated flute") drill bits are used in cutting applications where high cutting speeds are traditionally used, and where the material has a tendency to gall on the bit or otherwise clog the hole, such as aluminum or copper.

2. The point angle, or the angle formed at the tip of the bit: it is determined by the material the bit will be operating in. Harder materials require a larger point angle, and softer materials require a sharper angle. The correct point angle for the hardness of the material controls wandering, chatter, hole shape, wear rate, and other characteristics.

(To be continued. This article is divided into several parts. Here is part 2. For part 1, please refer to http://news.chinatungsten.com/en/tungsten-information/80546-ti-10416; for part 3, please refer to http://news.chinatungsten.com/en/tungsten-information/80548-ti-10418)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com