Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅶ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:50

- Written by zhihua

- Hits: 322

In last part we know that as the main tool failure mode, flank wear of (Al,Cr)N coated tungsten carbide tool is slower than the (Ti,Al)N coated one. And this part we will get to understand of the wear mechanism of the two coating films on tungsten carbide tools.

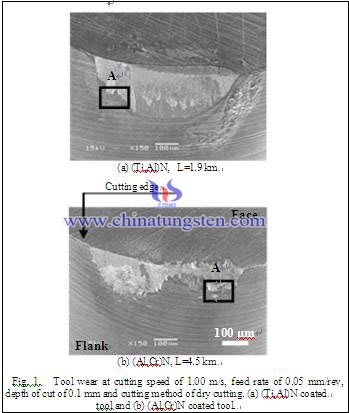

Fig. 3 shows the SEM observation and EDS mapping analysis on the worn surface of the (Ti,Al)N coated tungsten carbide tool and the (Al, Cr)N coated tool. Fig.3 (a) shows the details of “A”shown in Fig. 1. Fig. 3 (b) shows the EDS analysis in the case of the oxygen (O) mapping on the cutting part shown in Fig. 1.

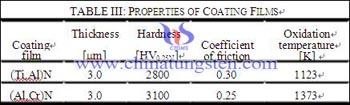

First, as compared with the worn surface of (Ti,Al)N coating film indicated by “B” shown in Fig. 3 i(a) and that of(Al,Cr)N coating film indicated by “B” shown in Fig. 3 ii(a), many striae scratched by a hard material are remarkably found on the worn surface in the case of both the (Ti,Al)N and the (Al,Cr)N coating film. Therefore, the main wear mechanism of both the (Ti,Al)N and the (Al,Cr)N coating film is considered to be abrasive wear. In the case of abrasive wear, the wear-resistance of the coating film often depends on the hardness of the coating film. That is, a coating film with higher hardness has good wear-resistance. So the characteristics of the coating films were investigated. The results are shown in Table III. The thickness of coating of (Al,Cr)N film is 3 μm, which is the same as that of (Ti,Al)N film. The (Al,Cr)N coating is harder than the (Ti,Al)N coating because the wear progress of (Al,Cr)N is considered to be slower than that of (Ti,Al)N.

(To be continued. This article is divided into several parts. Here is part 7 For part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/80627-ti-10436; for part 8 please refer to http://news.chinatungsten.com/en/tungsten-information/80629-ti-10438)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅵ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:46

- Written by zhihua

- Hits: 323

In last part we know that after testing, tungsten carbide tools with (Al,Cr)N coating film exhibit much better wear resistance quality than with (Ti,Al)N coating. In this part we will get to a closer analysis of the flank wear feature of the two coated tungsten carbide tools.

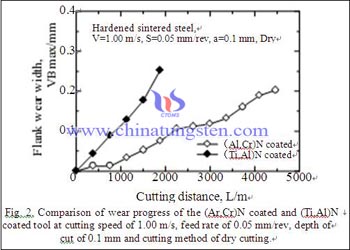

Following these experiments, it emerged that the main tool failure for two kinds of coated tools in cutting hardened sintered steel was the flank wear within a maximum value of the flank wear width of about 0.2 mm. Therefore, the maximum value of the flank wear width (VBmax) was measured by microscope.

Fig. 2 shows the wear progress in cutting two kinds of coated tools at a cutting speed of 1.00 m/s. The wear progress of the (Al,Cr)N coated tool is slower than that of the (Ti,Al)N coated tool. As mentioned above, the (Al,Cr)N coated cemented tungsten carbide tool is an effective tool material in cutting hardened sintered steel, so Scanning Electron Microscopy (SEM) observation and Energy Dispersive X-ray Spectrometer (EDS) analysis were carried out on the worn surface.

(To be continued. This article is divided into several parts. Here is part 6. For part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80617-ti-10434; for part 7, please refer to http://news.chinatungsten.com/en/tungsten-information/80628-ti-10437)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅴ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:50

- Written by zhihua

- Hits: 336

In last part we know that the tungsten carbide tools PVD-coated with (Ti,Al)N and (Al,Cr)N coating films are tested in cutting hardened sintered steel to compare the effect, since (Al,Cr)N coating film is a new film. In this part we will get result and make analysis.

Results and Discussion

The hardened sintered steel was turned with two kinds of coated cemented tungsten carbide tool at a feed rate of 0.05 mm/rev and a depth of cut of 0.1 mm. Fig.1 shows the SEM observation of the tool wear. Fig.1 (a) and (b) show the case of the (Ti,Al)N coated and the (Al,Cr)N coated tool at a cutting speed of 1.00 m/s, respectively. In the case of the (Ti,Al)N coated tool shown in Fig. 1 (a), a crater is found on the rake face along the cutting edge, and adhesion on both the rake and flank faces is not remarkable either. Also, the flaking of the coating layer is not remarkable. In the case of the (Al,Cr)N coated tool shown in Fig. 1 (b), there is no remarkable crater on the rake face. And adhesion on the flank face is found, while the flaking of the coating layer is also unremarkable.

(To be continued. This article is divided into several parts. Here is part 5. For part 4, please refer to http://news.chinatungsten.com/en/tungsten-information/80616-ti-10433)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Coating Materials for Tungsten Carbide Drill Bit

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:42

- Written by zhihua

- Hits: 283

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅳ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:47

- Written by zhihua

- Hits: 287

In last part we know that the study is to explore the effectiveness and wear mechanism of tungsten carbide tool with (Al,Cr)N coating film coated by PVD technology in turning hardened sintered steel.This part goes on explaining how the experiments go.

2. Experiment Details

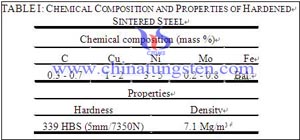

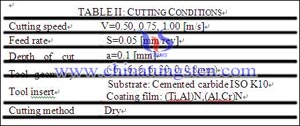

The work material used was hardened sintered steel from diffusion alloyed powder. This material had a density of 7.1 Mg/m3, and many pores were observed when examining the structure by microscope. The chemical composition and the mechanical properties of the hardened sintered steel are shown in Table I. That is, the hardened sintered steel had a hardness of 339 HBS. The cutting conditions are shown in Table II. The tool material of the substrate was cemented carbide, and two types of PVD-coated cemented tungsten carbide tool were used. Namely, the coating films used were (Ti,Al)N and (Al,Cr)N coating film. (Al,Cr)N is a new type of coating film. The configurations of tungsten carbide tool inserts were TNGA160408. The insert was attached on the tool holder MTGNR2525M16. In this case, the tool geometry was (-6, -6, 6, 6, 30, 0, 0.8 mm). The turning tests were carried out on a precision lathe (Type ST5) with an added variable-speed drive. The driving power of this lathe is 7.5/11kW and the maximum rotational speed is 2500 min-1. The tool wear of the two kinds of turning insert was investigated.

(To be continued. This article is divided into several parts. Here is part 4. For part 3, please refer to http://news.chinatungsten.com/en/tungsten-information/80615-ti-10432; for part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80617-ti-10434)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com