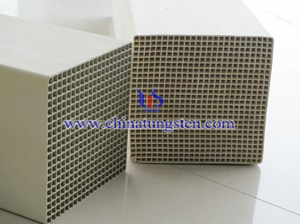

WO3 Loaded High-Temperature Exhaust Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 May 2016 18:48

- Written by chunyan

- Hits: 409

The high-temperature combustion exhaust from thermal power stations or gas turbine contains nitrogen oxides, nitrogen oxides need to be removed for achieving the clean emissions. Currently, the common used is the medium-temperature denitration catalyst, if the temperature is higher than 450°C, ammonia itself as a reducing agent will carry out the oxidation reaction. Ammonia is effective for the reduction of nitrogen oxides, but as the temperature rising, the denitration performance of ammonia will reduce in the presence of a catalyst.

The high-temperature combustion exhaust from thermal power stations or gas turbine contains nitrogen oxides, nitrogen oxides need to be removed for achieving the clean emissions. Currently, the common used is the medium-temperature denitration catalyst, if the temperature is higher than 450°C, ammonia itself as a reducing agent will carry out the oxidation reaction. Ammonia is effective for the reduction of nitrogen oxides, but as the temperature rising, the denitration performance of ammonia will reduce in the presence of a catalyst.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

LECO Carbon Sulfur Analyzer and Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 May 2016 18:42

- Written by xuejiao

- Hits: 358

LECO brand initially established in 1936 that is an abbreviation of Laboratory Equipment Corporation. In 1936, the brand launched the first commercial analyzer of carbon, sulfur, nitrogen, oxygen, hydrogen in the world, pioneering a precedent for analysis and the rapid analysis technology of industrial equipment. LECO decades has been maintained its leadership in analysis techniques. Currently, it has a diversified product line of laboratory analytical instruments, possessing the leading competitive products in the field of HX-MIAS, spectrum analyzer, gas chromatograph, which is widely used in various industries. LECO devote itself to develop and improve various analytical techniques and equipment for many years that brings more technology to more industries that need better, faster results. For example, LECO carbon sulfur analyzer occupies a large market in element analyzer areas, so in the late 1970s, this brand’s carbon and sulfur analyzer had to enter the Chinese market, there are more than 3,000 users and over 4000 instruments in China.

With the common using of LECO carbon sulfur analyzer in China, and its maintenance and other after-sales service is constantly being improved. In China, there are more than a dozen technical engineers with a professional and technical training to provide high-quality services for the maintenance of the analyzer. In order to reduce the rate of equipment failure, LECO has developed equipment maintenance contracts, within a predetermined range, a professional maintenance personnel will check up and repair the analyzer regularly inspection and maintenance in order to keep it in a normal working condition.

This brand's carbon sulfur analyzer series uses Cornerstone software for analyzing that allows users to achieve a complete control of analysis, method setting, online diagnostics, data reports. This software technology allows users to complete all the work routine analysis in an interface, which only needs for a short time and easy to operate. Tungsten granule has a good fluxing effect, the using of tungsten particles as the flux of carbon sulfur analyzer will greatly enhance the accuracy of the analysis results.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Container For Radioactive Liquid Waste

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 May 2016 18:28

- Written by minghui

- Hits: 259

With the development of atomic energy industry and the wide application of various radioisotopes, radioactive waste is gradually increasing. Radioactive waste is waste that contains radioactive material. It is usually a by-product of nuclear power generation and other applications of nuclear fission or nuclear technology, such as research and medicine. According to the physical properties of radioactive waste, it can be divided into radioactive gas waste, radioactive liquid waste and radioactive solid waste. Radioactive liquid waste means radioactive waste produced during the process of operation and treatment for radioactive materials, the radioactivity of which not only will pollute the environment, affect the growth of plants and animals, and result in water deterioration, but also can be hazardous to human health, and even has adverse effects on the offspring.

With the development of atomic energy industry and the wide application of various radioisotopes, radioactive waste is gradually increasing. Radioactive waste is waste that contains radioactive material. It is usually a by-product of nuclear power generation and other applications of nuclear fission or nuclear technology, such as research and medicine. According to the physical properties of radioactive waste, it can be divided into radioactive gas waste, radioactive liquid waste and radioactive solid waste. Radioactive liquid waste means radioactive waste produced during the process of operation and treatment for radioactive materials, the radioactivity of which not only will pollute the environment, affect the growth of plants and animals, and result in water deterioration, but also can be hazardous to human health, and even has adverse effects on the offspring.

Radioactive liquid waste which has a harmful effect on human health can produce radiation to damage human tissue and organs. Radioactive liquid waste not only can cause external radiation damage outside the human body, but also can enter the body by eating, breathing and other ways to cause internal irradiation. Therefore, the cases of human or animals breathe the radioactive material released in the atmosphere by radioactive liquid waste or accidentally ingest radioactive waste will cause radiation sickness. According to reports, 400rad doses of radiation exposure can lead to the mortality rate of 50%; 650rad doses of radiation exposure can lead to the mortality rate of 100%. Although the mortality rate drop down to zero in the doses of radiation exposure below 150rad, but it can also cause long-term irradiation effects, including causing leukemia, bone cancer, lung cancer, thyroid cancer and other cancers, as well as causing varying degrees of shortened life expectancy, and these symptoms may take 20 years to show it. In addition, radiation can lead to dizziness, hair loss, erythema, decreased immunity, fatigue, weakness and other symptoms. Therefore, you can use tungsten alloy container for radioactive liquid waste to storage and treat radioactive liquid waste.

Tungsten alloy container is the best choice for radioactive liquid waste. Compared with the lead container, high-density tungsten alloy container for radioactive waste can provide the same radiation absorption rate, while using less material than the lead container. And tungsten alloy container for radioactive liquid waste has very high melting point so that can be used in high temperature environment while lead cannot. Moreover, tungsten alloy container for radioactive liquid waste is extremely environmentally and friendly.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Operational Principles of LECO Carbon Sulfur Analyzer and Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 May 2016 18:40

- Written by xuejiao

- Hits: 320

As a new and high-tech level analyzer, carbon sulfur analyzer is widely applied in analyzing the content of carbon and sulfur of the alloy, cast-iron, lime and other solid and fluid materials. It has a high accuracy and a wide measurement range when analyze carbon and sulfur. The modular and integrative design of the whole structure of the analyzer achieves an easier operation, a faster analysis, a greater precision of analysis, a more reliable working of instrument. LECO carbon sulfur analyzer has been kept a leading edge in its technology, and has a number of technology patents, which has become the most well-known brands of analytical instruments in the world.

Operational principles of LECO carbon sulfur analyzer and tungsten granule mainly include the operation procedure before starting, the opening of host, the entering of the main program, dank correction and the shutdown operation. First of all, startup the UPS equipment, the power supply is checked to ensure whether it can be used normally or not. Then turn off the air switch and the stabilized voltage supply, check whether the output stabilized voltage supply is 220V or not. Under normal circumstances of the input of power, then get into the boot process. Next, open the air supply of the carrier gas O2 and power gas Ar, and adjust it into the appropriate pressure.

The carrier gas O2 is 0.26MPa, power gas Ar is 0.26MPa. Firstly, turn off of power switch of the furnace equipment (switch is located in the front of lower part of the stove, a black switch), then turn off the power switch of the instrument detector. You can see that some electronic tube is lit in the furnace crucible, the flowmeter of the float should be placed at 3L / min. The mainframe computer and monitor power is turned on while the printer power and balance power is turned on. Since the balance is in balance and it display 0.0000, double-clicking the CS230 icon on your desktop, entering CS230 analysis process.

After the analyzer and computer communication can be carried out normally, checking the air leak condition, then enter the sub-menu to view corresponding parameters and graphics, the next step is to be tested after a stable of data in detection pool. Finally, turn off the software first before shutting down, then turn off the switch and the analyzer switch in the front of stove, then turn off the gas source, and the power.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Drinking Influence on Darts Sport

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 May 2016 17:25

- Written by yaqing

- Hits: 308

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com