Double Action Pressing of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 14 July 2017 17:55

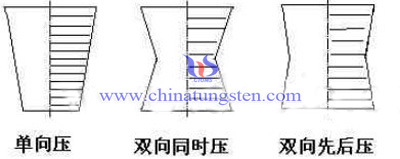

It can be classified into coincident double action pressing and non-coincident double action pressing.Cavity block hold still,up-down punch co-pressing at both ends,also known as coincident double action pressing.If go on single direction pressure first,then reverse single action pressing at lower density,it known as nonsynchronous double action pressing.

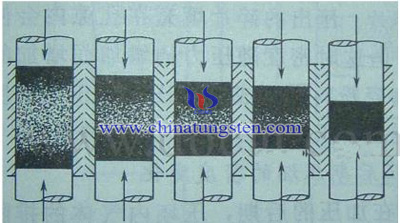

Simultaneous double action pressing:

The density partition feature of coincident double action pressing is:big up and down,small middle,density range smaller than single action pressing.Mainly because compare with single direction pressure,though double action pressing will not decrease frictional resistance in the forming conditions,but the valid outreach of pressure reduced to half its amount , because of the frictional force lead to pressure losses reduced to half its amount too, so as the homogeneity of green density can increase.

Non-coincident double action pressing( post-pressing):

To use one after another compression tactic,that is to divided into two inflating,forcing at one end,and them forcing at another end.This forcing mode is contribute to pressure transmission and gas elimination,pressure time is longer,go through post-pressing forcing,the homogeneity of the density can further improve.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com