How to Throw A Perfect Tungsten Dart

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 16:39

Practice does not make perfect if your form is all wrong. There is a technique to throwing the perfect tungsten dart that will have to be utilized every single time. Your form and technique is what makes an accurate shot happen. The instructions of throwing a perfect tungsten dart are as followed:

Understanding the basics of throwing is very important. Your arm determines where the tungsten dart is going to hit and once you learn and perfect this, you will be able to hit where you want to every time.

The parabolic curve is how the tungsten dart will fly through the air. This is the same curve that bullets and baseballs fly on. Achieving this curve is by holding your arm straight out, bending it at the elbow. Keeping this form and holding it will lead to success.

With the tungsten dart in your hand, take aim at where you want it to go. Keep focusing on the spot you picked and not the dart itself. Once that is decided, make sure to keep your shoulder straight at all times. Release the tungsten dart, following through with your arm all of the way. When you start to throw, go slower and then gradually speed up.

Once you get the form down of how to throw the perfect tungsten dart, you will be doing it every time. Your technique will get better and better the more that it is used.

Trying to do tricks, like spinning or twisting the tungsten dart, will interfere with the parabolic curve and the tungsten dart will most likely not land where you intend for it to go.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Scram Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 16:37

Scram tungsten dart rule is a really fun game for two players that are played in two parts.

The Object: To score a higher score than your opponent after you've each had a turn as "scorer" and "stopper".

The Scoring: Each player throws one tungsten dart at bullseye, closest to the bullseye chooses to be the "stopper" or the "scorer". The "stopper" always goes first.

Players names are written in order across the top of the board with the numbers 1 through 20 and bullseyes written down the center of the board dividing the board into two columns.

The Play: The "stopper" plays first and throws three tungsten darts into different numbers. Each number that is hit is "stopped". Stopped numbers are shown by placing an X next to the numbers. Any part of the number may be hit to stop it.

After the stopper throws, the scorer now tries to score as high a score has possible with three tungsten darts. Any numbers that have been stopped, do not count towards a score. Any other numbers that have not been stopped count in the usual way. The thin inner "triples" ring counts as three times the number hit and the thin outer "doubles" ring counts as twice the number hit. Bullseyes count as 25 points and the double-bullseye counts as 50.

The scorer's score is kept as a running total and written on the scorer's side of the board. Once all the numbers and the bullseyes have been stopped, the round is over. The roles now reverse and the original stopper tries to score points while the original scorer stops numbers.Whoever has the higher total at the end of two rounds wins the game.

Strategy: Use your opponents strenghts and weaknesses against him/her. For example, I can't hit 18's to save my life but I can't be stopped on 16's and 19's. So, if you were playing me and new this, you should try to stop 19's and 16's first and let me flounder on the 18's all I want. Obviously it is important to try to stop the higher numbers first, though.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Tungsten Radiation Protective Tank

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 14:40

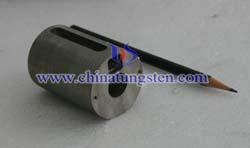

Because tungsten for X-ray attenuation ability is used for all kinds of radioactive source shielding components or container of a kind of ideal material. In addition, tungsten is high density and environmental friendly. Tungsten is usually used to produce into tungsten radiation protective tank for industry and medical applications.

Tungsten radiation protective tank is used as medical tungsten radiation shielding for medical radiation shielding wall. Tungsten can be produced as needle radiation shielding for medical radioactive liquid shielding. Tungsten radiation protective tank can be used as cans, boxes and other containers used to store radioactive matter, collimator, for medical linear accelerator and nuclear technology applications in tungsten series test container system collimator, Co60 radiation shielding.Tungsten radiation protective tank can be used widely in industry, such as the radiation shielding for radiation detectors, and nuclear industry radiation protection. Tungsten radiation protective tank for shielding X-ray and gamma radiation can greatly enhance both the material properties and the shielding efficiency.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Extrusion to Manufacture Tungsten Alloy Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 14:37

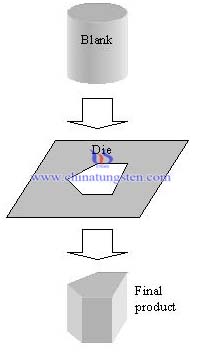

Extrusion is a process used to create objects of a fixed cross-sectional profile. The extrusion process is one important step to manufacture tungsten alloy radiation shielding. Tungsten alloy can be pushed or pulled through a die of the desired cross-section. The extrusion process may also increase the strength of tungsten alloy.

Extrusion is a process used to create objects of a fixed cross-sectional profile. The extrusion process is one important step to manufacture tungsten alloy radiation shielding. Tungsten alloy can be pushed or pulled through a die of the desired cross-section. The extrusion process may also increase the strength of tungsten alloy.

The process begins by heating the stock material (for hot or warm extrusion). It is then loaded into the container in the press. A dummy block is placed behind it where the ram then presses on the material to push it out of the die. Afterward the extrusion is stretched in order to straighten it. If better properties are required then it may be heat treated or cold worked. The extrusion ratio is defined as the starting cross-sectional area divided by the cross-sectional area of the final extrusion. One of the main advantages of the extrusion process is that this ratio can be very large while still producing quality parts.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ferrous Tungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 14:09

The chemical formular of ferrous tungstate is FeO4W and molecular weight is 303.6826g/mol. Besides the monoisotopic mass and exact mass is 303.865527g/mol, on the other hand, the PubChenm of it is 22178528.

Highly crystalline FeWO4 nanoparticles (NPs) were synthesized via the hydrothermal synthesis method while amorphous FeWO4 NPs were prepared by the room temperature precipitation method. It was found that a dissolution-recrystallization process appeared due to the Ostwald ripening when room temperature precipitates undergo the hydrothermal process. Photocatalytic performance toward the degradation of methylene blue showed that crystalline FeWO4 NPs displayed a higher activity than amorphous samples, mainly ascribing to the substantial elimination of defects after crystallization because the defects promoted the recombination of electron-hole pairs.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungstate Mercury Producing

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 14:05

Tungstate mercury producing processes are as follows:

1.Weigh 0.01 ~ 0.02mol tungsten and mercury salts separately. On one hand, mercury salts and tungsten molar ratio is 1: 1. On the other hand, the mercury salts may be selected from HgCl2 or Hg (NO3) 2 in which tungsten may be selected Na2WO4, K2WO4 or H2WO4 one of them. Then place them in a 45ml autoclave with tetrafluoroethylene-lined, and then adding distilled water to 3/4 volume of autoclave.

2.Adding N2 into reaction solution to get rid of dissolved oxygen in reaction solution. After sealed the autoclave and put it into oven heating at 140~200℃ for 2~12 hours. And after completion the reaction, closed the oven to reduce the temperature of autoclave by gradient.

3.Using the dropper to take the supernatant of the autoclave and the precipitation put into beaker. After ultrasonic treatment for 5 minutes to 6 hours and then stewing for 1 to 5 hours followed by centrifugation.

4.The resulting precipitate which was got by centrifugation washed with distilled water, acetone and ethanol for three times with separately, finally get mercury tungstate mercury.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sodium Metatungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 14:03

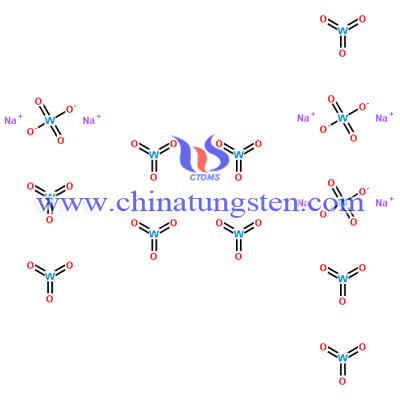

Sodium metatungstate also known as hexasodium tungstate hydrate and it is a white crystal. Its physical properties are shown below: chemical formula: Na6O39W12, the molecular weight: 2968.01, density: 3.1g/ml, refractive index: 1.5555. Related systems numbers of Na6O39W12 are as follows: CAS registry number: 12141-67-2, MDL number: MFCD00061466, EINECS number: 412-770-9, PubChem ID: 24886321. Sodium metatungstate is stable at room temperature and atmospheric pressure, but to avoid contact the material and oxide and it should be sealed and stored at room temperature which somewhere is ventilated and dry.

Sodium metatungstate to water has a certain degree hazard and even a small amount of this product contact with groundwater will pollute the drinking water. So without permission from the relevant government cannot release the material into the surrounding environment. Meanwhile, the products have a certain irritation, if accidentally touching the eyes and skin to use plenty of water clean it and go to hospital to treatment. Therefore, during at the operation, the worker should to take some protective measures, such as wearing protective glasses, protective masks and protective clothing and so on.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Properties of Tungsten Mine Waste Geopolymeric Binder- Introduction II

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 10:29

This is the second part introduction of properties of tungsten mine waste geopolymeric binder.

However, there is little research published, about geopolymeric binders synthesized from mine and quarry wastes. Studies concerning the geopolymerization of different minerals suggest that a wide range of Al–Si based minerals could be used as source precursors. However one should notice that those studies used high purity geological specimens, so mine waste mineral will hardly behave just like it.

Panasqueira is an underground mine situated in central Portugal on the southern edge of the Sierra da Estrela mountain range, a natural park, near the Sierra do Ac¸or, a protected landscape, and also near the Zezere river. Tungsten and tin have been mined in the Panasqueira area since the 1890s. During the mining process two types of mine waste are generated, coarse aggregates derived from rock blasting and waste mud conveyed by pipelines into lagoons amounting for several million tonnes and still generating almost 100 tonnes per day. Previous studies concerning the alkali-activation of TMWM together with a small percentage of calcium hydroxide suggests that a geopolymeric binder with extremely high early age strength can be produced. This paper reports the experimental results on some physical and mechanical properties of TMWM binders.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Properties of Tungsten Mine Waste Geopolymeric Binder- Introduction I

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 10:25

This is the first part introduction of properties of tungsten mine waste geopolymeric binder.

Studies of alkali-activated cements have a long history in the former Soviet Union, Scandinavia, and Eastern Europe. In 1978, Davidovits created the term ‘‘geopolymer’’, to characterise new materials with the ability to transform, polycondense and adopt a shape rapidly at low temperatures like ‘‘polymers’’. The polymerisation process involves a chemical reaction under highly alkaline conditions on Al–Si minerals yielding polymeric Si–O–Al–O bonds with empirical formula Mn [–(Si–O2)z–Al–O]n. wH2O, where n is the degree of polymerization, z is 1, 2 or 3, and M is an alkali cation, such as potassium or sodium. Davidovits reported several advantages of geopolymeric cementitious systems over Portland cement mainly environmental, due to the fact that geopolymeric based concrete has a much longer service life than Portland cement based ones, to the metals waste encapsulation capacity and to lower CO2 emissions. The geopolymerization requires a precursor that contains significant quantities of silicon and aluminium held in an amorphous phase such as ashes from power stations or mining and quarrying wastes.

Over the last years several authors have reported research in a large number of aspects related to geopolymeric based binders such as: dependence of the nature on source materials (geopolymers synthesised from calcined sources show a higher compressive strength than from raw materials), immobilization of toxic metals, reaction mechanisms and hydration products, the role of calcium in geopolymerization, manufacture operations and even the development of lightweight building materials.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Dressing-II

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 09:44

Tungsten ore dressing methods are mainly hand-selected, HM election, re-election, flotation, magnetic separation and electrostatic separation. Wolframite in order to re-election dominated while scheelite flotation mainly associated. To the full recovery of useful components, improving the quality and tungsten concentrates recycling rate, currently the trend of dressing and smelting technology combined to increase the baking and Leaching and other hydrometallurgical refining methods.

Many types of tungsten ore in earth, there are mainly two; black tungsten ore (wolframite) and scheelite (calcium tungsten ore). There is a variety of ore mineral paragenesis, in order to pass the quality of mineral concentrate to meet the requirement and the associated recovery of useful mineral, generally based on the major component of the ore, taking into account the characteristic of associated component, selection process consisting of two or more method.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com