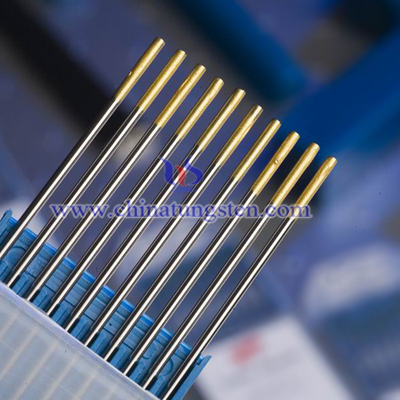

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Abstract

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 19:06

This specification prescribes the requirements for the classification of bare tungsten and oxide dispersed tungsten electrodes for gas tungsten arc welding and cutting and plasma arc welding and cutting. Classification is based on the chemical composition of the electrode. Standard sizes, finish, lengths, quantities, product identification, color coding, and chemical composition limits are specified.

This specification makes use of both U.S. Customary Unites and the International System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

This specification adopts the requirements of ISO 6848:2004 and incorporates the provisions of earlier versions of AWS5.12, allowing for classifications under both specifications.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Venturi Nozzle Used in Shot Peening III

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:19

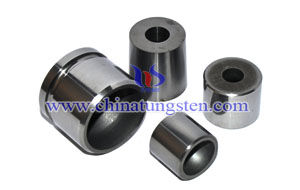

Tungsten carbide venturi nozzle has excellent uniform distribution of grinding compound. It is different with common straight type nozzle, which gathers the most of grinding compounds in the center of divergent area and narrow effective clean-up width, tungsten carbide venturi nozzle has wider effective clean-up width, more uniform grinding compound force. So that it can obviously improve the efficiency 15%--40% and reduce the consumption of the grinding compound.

In addition, there is a unique two-venturi nozzle, which has two nozzles at front and rear. Besides, there are some pores between two nozzles. Under the circumstances, it inhale surrounding air and make the volume of spraying is larger than the compressed air to accelerate the speed of grinding compound output. This diameter of two-venturi nozzle exit is longer than tungsten carbide venturi nozzle, smaller impulsion and 35% diverging area larger than normal nozzle so that the efficiency is improved.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Venturi Nozzle Used in Shot Peening II

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:17

Tungsten carbide venturi nozzle structure can be divided into three parts, which is straight segment, shrinking segment and diffusion segment. So its process is more complicated than common nozzle. In terms of gas dynamics performance, tungsten carbide venturi nozzle is better than straight type nozzle, which has low pressure loss, improves vortex phenomenon. Under the same pressure, the speed of grind compound entrance can be up to 1 times higher than the normal, even close to the speed of sound. Therefore, the kinetic energy of the grinding compound has been remarkably improved, the impact has been significantly strengthened, which enhance the efficiency of tungsten carbide venturi nozzle and reduce the cost of production.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Venturi Nozzle Used in Shot Peening

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:15

Shot peening process is similar to sandblasting processing, the only distinction is grinding compound is different and shot peening needs more air pressure. It is widely used in surface strengthen, polishing and deoxidation to eliminate forging residual stress which requires simple equipment, lower cost and not limited by the shape of material and the space. Shot peening materials contains cast iron balls, steel balls, glass balls and pottery balls, and the glass ball has high requirements, which should be above 6-7 Moh’s hardness. Otherwise, it will be fragile under high-speed impact and increase the cost. After shot peening process, the material will be harder, tougher and has better anti-corrosion and fatigue strength, extends their lifespan.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Deep Cryogenic Technology III

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:12

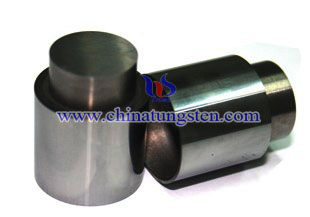

Tungsten carbide nozzle is mainly composed of WC hard phase and Co binder phase. It is essential that hard phase ensure the high hardness, toughness and good heat resistance. While the binder phase has a polymorph characteristic, and usually plays a very important role in physical and chemical action in cemented carbide sintering process. X-ray diffraction analysis showed that the grain within tungsten carbide has structural change and increases the number of sub-grain boundaries per unit volume.

The sub-grain boundary structure is unique, which will enhance the shear stress plastic deformation resistance of the alloy so that the plastic deformation of tungsten carbide becomes difficult. Therefore, changes in internal microstructure reflected in the macroscopic properties change is to improve the ability of anti-abrasion synthetic polymers as well as its own resistance to abrasion, erosion resistance and service life have been significantly extended.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Looper Tungsten Dart Rule Ⅱ

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 16:50

Looper tungsten dart rule is a very simple yet fun game to play. It is very similar to the basketball game "Horse". It may be played by any number of players and is more fun with a lot of people. This game is actually pretty boring with only two players.

For example, a player has to hit "S5" (the small wedge of the 5). With the first tungsten dart he hits the "S5". He now has two tungsten darts to set a new target. He aims at double bull ("D25") and hits it. He may now choose to sit down and not throw the third tungsten dart and leave the "D25". Let's say that, for some insane reason, he decides to try for a double 18, and misses off the board. He now loses a life and the next player now must hit "S5". The next player now gets up and hits the "S5" on his third tungsten dart. He pulls his darts and throws his first dart and hits "T20" (triple 20). Satisfied, he sits down choosing not to throw the other two darts.

If a player sets a target and all other players fail to match the target, when it's that players turn again, no throw is necessary. The player may choose to stay seated and keep the same target number. If the player chooses to risk trying a turn, the player MUST hit the target same as everyone else. If the player misses a life is lost just as if he did not set the number that stumped everyone else. It is usually wiser to just leave the number and not take the risk.

"So why do they call this 'Looper'?" The reason is that Closed loops of the numbers around the outside of the board count as valid targets! For example the loop that makes up the lower half of the number 6 is a target, however the upper hook of the 6 is not. These are written as "L", for example "L16" would meant the loop of the 16. The 8 and 18 each have two valid loops and which one is hit does matter. They would be notated as "UL8" for upper loop of the 8 or "LL8" for lower loop of the 8. As you can imagine loops are very hard to hit and are also very risky, if you miss slightly, you did not set a target number. However, if you do hit a loop, the other players have the difficulty of matching it.

Strategy: The only real strategy here is one of opportunity. If you hit the target number and have at least two tungsten darts to set a new one, try one dart at a loop. If you hit it sit down. If you don't, make sure you hit a new target even if it's an easy one with your last tungsten dart. Remember, hitting a big fat 16 and giving the next player an easy target is better than losing a life because your threw all your tungsten darts at a loop and missed or having a bounce-out with your last tungsten dart aiming for that double bull.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Looper Tungsten Dart Rule Ⅰ

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 16:48

Looper tungsten dart rule is a very simple yet fun game to play. It is very similar to the basketball game "Horse". It may be played by any number of players and is more fun with a lot of people. This game is actually pretty boring with only two players.

The Object: To win the game you must be the last player to have any lives left.

The Scoring: Players names are written in any order down the left side of the scoreboard. Usually, a throw of one dart each at bulls-eye with the closet player throwing first and the furthest throwing last. After the first game, the first player to get knocked out plays first and so on. Three tallies are marked next to each name to indicate the number of lives left.

The Play: The first player throws one dart left-handed (or right-handed if that player is a lefty) to set a random target. Because the first player has no chance to lose a life, the random throw is used to give the second player a fair chance.

The exact wedge or bulls-eye the tungsten dart landed is marked on the scoreboard. If the dart lands in the 5 between the triple ring and the bulls-eye, you would mark "S5" to indicate the small wedge of the 5. If the dart landed in the triple 5, you would write "T5". If the dart landed in the 5 between the triple and the double rings, you would write "B5" to indicate the big wedge of the 5. If the tungsten dart landed in the double 5, you would write "D5".

The next player now must try to land a tungsten dart in the exact same wedge of the board. If that player is unsuccessful with all three tungsten darts, one life is erased and the next player has a chance.

If the player is successful in matching the wedge any tungsten darts remaining in hand may now be used to score a new target. If the target was hit with the third tungsten dart, the player pulls the tungsten darts and has all three to establish a new target. All three darts need not been thrown in a turn the player may stop at any time after the number was matched and the last dart thrown at the board is the new target. The player may not make a choice of the tungsten darts thrown, only the last dart counts. If the player misses the board with the last dart that can be thrown, a life is lost and the target remains at the previous one set.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Industry Developments-VIII

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 14:07

In January 2012, Thor Mining PLC (Thor) reported Indicated Resources of 3.8 Mt at 0.29% WO3 and 0.22% molybdenum disulphide (MoS2) and Inferred Resources of 0.9 Mt at 0.25% WO3 and 0.25% MoS2 for the company's Molyhil Tungsten and Molybdenum Project, 220 kilometres northeast of Alice Springs in the NT. Reserve figures for the deposit, reported in April 2012, include open cut Probable Reserves of 1.64 Mt grading 0.42% WO3 and 0.13% MoS2. Potential development of the project was hampered by the global financial crisis and a decline in international metal prices, which resulted in the company scaling back activities. Thor had signed an off-take agreement with one of China's largest State-owned companies, CITIC Australia Trading Limited. The agreement was for CITIC to take all of the molybdenum and tungsten concentrates produced from the project, but that agreement has since lapsed. The recent increase in tungsten prices has resulted in renewed interest and in mid-2012 Thor completed a positive definitive feasibility study of the deposit, with a 4-year mine life based on current reserves. Thor has been attempting to secure agreements for off-take of tungsten and molybdenum concentrates before beginning development of the deposit. The company announced in October 2013 that it had received a letter of intent from United States-based Global Tungsten and Powders Corp. to purchase between 70 and 75% of the annual production of scheelite concentrate from Molyhil. Discussions for the remaining tungsten and molybdenum concentrates are continuing. Thor Mining has indicated it is undertaking an upgrade of its feasibility study.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Industry Developments-VII

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 13:47

Tasmania Mines Ltd (Tasmines) continued production of by-product tungsten (approximately 35 tonnes of WO3 in 2012) at its Kara magnetite mine, 35 kilometres south of Burnie in northwest Tas. The mine, which has been operating since 1977, produces magnetite and scheelite from skarn mineralisation that has replaced carbonates within Cambrian and Ordovician sediments close to the Devonian Housetop Granite. In January 2013, Tasmines released updated resource figures for the mine, including, at Kara No 1, total resources of 16.58 Mt at 49% iron oxide (FeO) and 440 parts per million (ppm) WO3, which includes Measured Resources of 10.21 Mt at 199ppm WO3, and Indicated Resources of 4.60 Mt at 714ppm WO3. In addition, updated resource figures for the Eastern Ridge Magnetite Skarn, are 6.50 Mt at 48.3% FeO and 0.10% WO3, which includes Indicated Resources of 5.24 Mt at 0.12% WO3 while at Kara North 266 and the Northern Magnetic Anomaly there is a combined Inferred Resources of 14.55 Mt at 43.5% FeO and 462ppm WO3. Ore reserves, as of January 2013, for the Kara No 1 pit comprise Proven and Probable Reserves of 13.07 Mt at 45.4% FeO and 340 ppm WO3 with 71% of the Reserves in the Proven category. Based on this reserve estimate, the company indicates a mine life of 18.4 years for the Kara No 1 pit.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Industry Developments-VI

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 12:00

In mid-2013, the Australian based company, Elementos Ltd (Elementos), acquired the Cleveland Tin project via a merger with the unlisted Rockwell Minerals Ltd (Rockwell), which previously controlled, and owned 50% of project. The Cleveland project in northwest Tas, 60 kilometres southwest of Burnie, includes the underground tin-copper (Sn-Cu) Cleveland mine which was mined by Aberfoyle Ltd between 1968 and 1986 and produced approximately 23.5 kt Sn and 9.7kt Cu. The mine closed because of low tin prices in the late 1980s. The Cleveland project also includes a large low-grade Sn-Cu tailings dam, as well as the Foley Zone tungsten deposit. The company has indicated it plans to undertake further drilling to test for extensions of tin and tungsten deposits. It also indicated in late 2013 that it had initiated a pre-feasibility study to assess the development potential of the hard rock and tailings dam tin and copper resources. The study, which is due for completion in the second quarter of 2014, will be based on a recently released (April 2013) JORC Code compliant resource for the Cleveland mine totalling 6119 kt at 0.68% Sn and 0.25% Cu, containing 42 kt of Sn. This includes Indicated Resources 4239 kt at 0.70% Sn and 0.28% Cu (contained 30 kt of Sn). A JORC Code compliant Inferred Resource of 3980 kt at 0.30% WO3, for a contained 12 kt of WO3, has been calculated for the associated Foley Zone tungsten deposit. Tungsten occurs as wolframite hosted within a quartz stock-work.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com