Tungsten Copper Electrode New Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 May 2016 17:28

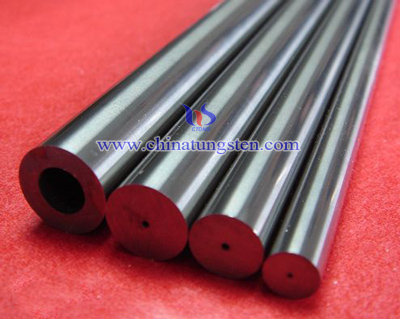

With the rapid development of EDM (Electrical Discharge Machining) industry, it has higher and higher requirements for the used electrode. Both tungsten copper with high content of W (mass fraction of W reaches 50%-90%) and tungsten copper with high content of Cu (mass fraction of Cu reaches 60%-90%), the most widely used are mixing method and infiltration method. Theoretically, the mixing method has simple operations and can fabricate tungsten copper products with any ratio of W and Cu. But the powder grain of raw material by this kind of conventional process is too large and the density distribution is uneven, which is difficult to fabricate tungsten copper electrode with compact structure after pressing and sintering process.

While the infiltration process is suitable to fabricate tungsten copper with 8%-40% content of Cu, tungsten skeleton infiltrated by copper in molten state to obtain the densification. Although the infiltration process is the most widely used in tungsten copper electrode now and it has stable working properties, it also has some problems, such as many controlling parameters, difficulties in porosity controlling, difficulties in porosity distribution and so on. So the relevant scholars and researches have further explosion surrounding the raw material preparation and molding process in recent years. Some new technology has gradually developed, which is more practical and operational effects are:

1. Pre-alloying: Its powder refinement and even micro-alloying, so as to achieve increased activity and split the purpose of promoting densification by mechanical and high energy ball milling;

2. Ultrafine particle / nano powder: By the addition of grain growth inhibitors, high-energy ball milling, adding elements and changing the material of the powder form and other methods to refine, even to the nanometer level;

3. Thermoforming: it is pre-loaded with a good blend in the mold cavity, rapid molding under heat and pressure to achieve integration and briquettes pressed sintered compact so as to achieve the densification effect;

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Diesel Engined Car Exhaust WO3 Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 May 2016 17:13

Oxide catalyst is mainly the vanadium based catalyst, and adding co-agents like tungsten trioxide, such kind of catalyst has a high NOx removal efficiency in the temperature range of 300-400°C with excellent stability. In the past, the catalyst of diesel engined car exhaust is primarily the noble metal catalyst, but its application is limited by high cost. An invention has pointed out that a method for preparing the diesel engined car exhaust tungsten trioxide denitration catalyst which has a high catalytic activity, wide temperature window, as follows:

Oxide catalyst is mainly the vanadium based catalyst, and adding co-agents like tungsten trioxide, such kind of catalyst has a high NOx removal efficiency in the temperature range of 300-400°C with excellent stability. In the past, the catalyst of diesel engined car exhaust is primarily the noble metal catalyst, but its application is limited by high cost. An invention has pointed out that a method for preparing the diesel engined car exhaust tungsten trioxide denitration catalyst which has a high catalytic activity, wide temperature window, as follows:| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Denitration Catalyst Regeneration - Bubble Flow Device Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 May 2016 17:10

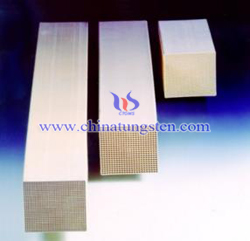

In the running, tungsten trioxide denitration catalyst will part or entire inactivated due to the fly ash poisoning and deposition of solids ect., and end its life after a certain period of time (approximately 2 to 5 years), therefore needs to be regenerated or obsolete processed. The bubble flow device (Air Lift Loop Reactor) can recover the activity of honeycomb SCR catalyst which deactivated from heavy metal poisoning in fly ash and solids deposition pollution ect. to the activity before polluted.

In the running, tungsten trioxide denitration catalyst will part or entire inactivated due to the fly ash poisoning and deposition of solids ect., and end its life after a certain period of time (approximately 2 to 5 years), therefore needs to be regenerated or obsolete processed. The bubble flow device (Air Lift Loop Reactor) can recover the activity of honeycomb SCR catalyst which deactivated from heavy metal poisoning in fly ash and solids deposition pollution ect. to the activity before polluted.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What Is Stamping Tungsten Boat?

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 May 2016 11:19

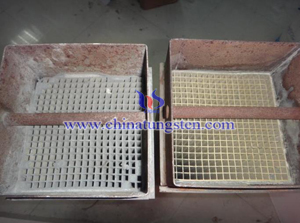

Stamping is also divided into forging, ginning, combining and other types. Processing of iron can be referred to as punching. Conventional press working method is cut, bent, twist. Also there are a variety of molds, including plastic, rubber molds, glass molds. Stamping dies are used for stamping, including arbitration die, progressive die, compound die, precision die, drawing die, bending die, molding, die cutting and other types of stamping dies, according to the differences of the finished product, users can choose different stamping dies.

At the beginning of it, tungsten plate should be blended into a certain angle, or bending the blended workpiece again. After that, it should be pressed into any hollow shape by mould, or bending the hollow mould workpiece further deformation. Afterward the hole or the outer edge of tungsten plate should be folded into a straight wall by mould. Forcing an outward radial force on the hollow member by mould, so that the local diameter can be expanded. After expansion, pressing the outside-in radial pressure on the hollow member so to narrow the local diameter. Next, putting the bloom into the die cavity, squeeze it out from the gap of mould to form the hollow or solid workpiece. Roll the panel into a ball peen whose shape approximate to a close one. Finally, press the bended or stretched workpiece into a right stamping tungsten boat shape.

The main features of the stamping W-boat is the high rate of final products. Because that this type of W-boat  adopting the stamping equipment and stamping mould, the accuracy of size and shape the stamping wolfram crucible are much higher. What’s more, it has a long life time and it is not easily to be damaged, therefore, the shape of the stamping tungsten boat from the same production batch is almost the same whose quality is also stable. However, during the stamping process, the device will produce noise and vibration which would have a great influence on operators. Furthermore, the mould is an essential material for stamping process, so the quality of the mould determines the quality of the W-boat.

adopting the stamping equipment and stamping mould, the accuracy of size and shape the stamping wolfram crucible are much higher. What’s more, it has a long life time and it is not easily to be damaged, therefore, the shape of the stamping tungsten boat from the same production batch is almost the same whose quality is also stable. However, during the stamping process, the device will produce noise and vibration which would have a great influence on operators. Furthermore, the mould is an essential material for stamping process, so the quality of the mould determines the quality of the W-boat.

Surface and internal performance of panel have a great impact on the quality of the finished product by stamping, it requires that the thickness of stamping material should be precise and without any spots, scars, bruises, surface cracks.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

AJ Carbon Sulfur Analyzer and Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 May 2016 11:16

Jena Analytik Jena AG brand, called AJ, was established in 1990 in Germany, which is evolved by Carl Zeiss Carl -Zeiss Jena GmbH. Nowadays, AJ carbon sulfur analyzer has become one of the most popular brands of analytical instruments in Germany. The brand is mainly focus on the development, design and manufacturing of total organic carbon (TOC) / total nitrogen (TN) analyzers, organic halogen compounds (AOX) analyzer elements (C, S, N, Cl) analyzer, atomic absorption spectrometer (AAS), ICP-OES emission spectrometers, inductively coupled plasma mass spectrometry and UV / visible (UV / VIS) light meter points and biochemical analytical instruments. Analytik Jena is a provider of analytical measuring technology, and life science instruments. With its core expertise in optical spectroscopy and elemental analysis its portfolio includes analytical systems for qualitative and quantitative analysis of liquids, solids, and gases.

Multi EA S® 5000 Elemental Analyzer is launched by AJ brand in 2008, which is a kind of multi-element professional analysis system for the analysis of total nitrogen, total carbon, total sulfur, total chlorine content of a variety of gaseous, liquid, LPG, solid samples. The instrument has many excellent features. Tungsten granule is used as the mainly flux, which can the accelerate reaction rate for the analysis process, shortening the time of determination. Its appearance and structure design is the main attraction, users can select the elements to be analyzed and the corresponding detector.

In the software you can choose to switch carbon and sulfur analysis, without any mechanical conversion. In addition, AJ carbon sulfur analyzer is a lightweight instrument, which does not require any maintenance vertical injector and a vertical furnace, so that it can ensure that good reproducibility of the instrument. After installation is completed, it doesn’t need any manual adjustment. Voltage stabilizing system in the gas circuit is equipped to avoid the pressure fluctuations while detecting. Any parameters of instrument are set and optimized and controlled by computer, which has the characteristics of full intelligence and full automation. Because the instrument has a heated filter device, there is no need for membrane dryers and detection system to be maintained repeatedly, which can greatly reduce operating costs.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

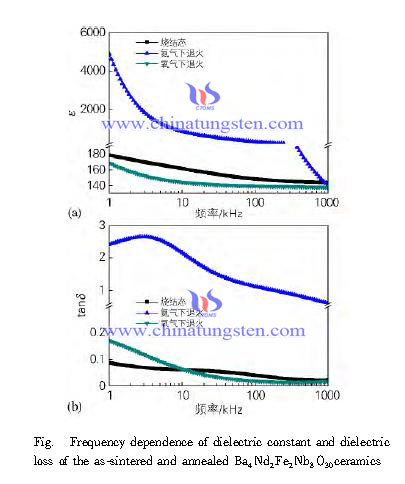

Annealing Effect on Tungsten Bronze Niobate Dielectric Properties

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 18:33

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding For Nuclear Electricity Generation

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 18:19

Nuclear electricity generation is the use of fissile materials in nuclear reactors (such as uranium-235, plutonium-239, uranium-233, etc.) that release thermal energy by nuclear fission to generate electricity. Nuclear fission is a radioactive decay process in which the nucleus of an atom splits into smaller parts. The fission process often produces free neutrons and gamma photons, and releases a very large amount of energy. A nuclear chain reaction occurs when one single nuclear reaction causes an average of one or more subsequent nuclear reactions, thus leading to the possibility of a self-propagating series of these reactions. Nuclear chain reaction is the precondition of nuclear electricity generation. Compared with thermal power generation, which uses thermal energy generated by the combustion of chemical fuels to generate electricity, the heat energy released from the nuclear reactor is much higher than that released from the combustion of fossil fuels, while the volume of fuels required is much less.

Nuclear electricity generation is the use of fissile materials in nuclear reactors (such as uranium-235, plutonium-239, uranium-233, etc.) that release thermal energy by nuclear fission to generate electricity. Nuclear fission is a radioactive decay process in which the nucleus of an atom splits into smaller parts. The fission process often produces free neutrons and gamma photons, and releases a very large amount of energy. A nuclear chain reaction occurs when one single nuclear reaction causes an average of one or more subsequent nuclear reactions, thus leading to the possibility of a self-propagating series of these reactions. Nuclear chain reaction is the precondition of nuclear electricity generation. Compared with thermal power generation, which uses thermal energy generated by the combustion of chemical fuels to generate electricity, the heat energy released from the nuclear reactor is much higher than that released from the combustion of fossil fuels, while the volume of fuels required is much less.

Fission fragment which is generated when the nuclear fission of nuclear fuels is radionuclide that will occur a series of decay with strong radioactivity (mainly are β-ray and γ-ray). β ray is a high-energy, high-speed electron or positron, whose penetrating power is stronger than α-ray. When it penetrates the skin, it can cause radiation injury. And when it enters the body, it will change the chemical balance of cells, causing cells to become cancerous and the genetic material DNA to be damaged; the penetrating power of γ-ray is also very strong, it can enter into human body to interact with cells in vivo, to damage the molecular components of living cells (such as proteins, nucleic acids and enzymes), leading the body's normal chemical processes to get disturbed, thus causing harm to humans. Neutron radiation emitted by nuclear reactor also has manifested the very strong lethality, it can cause organ failure, central nervous system and digestive system damage.

Tungsten alloy shielding can be used for shielding the radiation released from the process of nuclear electricity generation. Experts find that radiation exposure could be reduced by maxing shielding. The radiation shielding ability of a material is related to its density. Higher density means better radiation shielding ability. Due to a higher density, tungsten heavy alloy has a much higher radiation shielding ability than lead. Alternatively equal amounts of tungsten alloy shielding provide diminished exposure risks than equivalent lead shielding.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Energy Consumption and Metabolic of Tungsten Darts Sport

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 18:09

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

SCR Denitration Catalyst Recovers Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 17:07

Currently, working life of SCR denitration catalyst is generally 3~5 years, the commonly treatment ways of the deactivated catalyst are regenerating or landfill. Landfill will not only result in the occupation of land resources, but also a tremendous waste of resources. According to statistics, by 2018, it will produce annually 38,000 tons of waste SCR denitration catalyst, which contains 1520 tons of tungsten trioxide. Because tungsten is a rare metal and the very high price of tungsten trioxide, if the waste SCR catalyst can’t get reasonable treatment and the valuable resources can’t be recovered, the great waste of resources will cause.

Currently, working life of SCR denitration catalyst is generally 3~5 years, the commonly treatment ways of the deactivated catalyst are regenerating or landfill. Landfill will not only result in the occupation of land resources, but also a tremendous waste of resources. According to statistics, by 2018, it will produce annually 38,000 tons of waste SCR denitration catalyst, which contains 1520 tons of tungsten trioxide. Because tungsten is a rare metal and the very high price of tungsten trioxide, if the waste SCR catalyst can’t get reasonable treatment and the valuable resources can’t be recovered, the great waste of resources will cause.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Desulfurization Catalyst Used for Preparing Superior Grade White Oil

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 17:03

White oil, alias paraffin oils, mineral oils, is the highly refined colorless oily liquid with odorless, and has excellent chemical and light stability. It is widely used in industries such as cosmetics, food, pharmaceutical, plastics, chemical fiber, machinery and light industry.

White oil, alias paraffin oils, mineral oils, is the highly refined colorless oily liquid with odorless, and has excellent chemical and light stability. It is widely used in industries such as cosmetics, food, pharmaceutical, plastics, chemical fiber, machinery and light industry.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com