What Is the Electron Emission Capability of Lanthanum Tungsten Electrodes at High Temperature?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:23

In welding processes, especially those requiring a stable, high-temperature arc, such as argon arc welding (TIG) and plasma arc welding, the electron emission capability of the electrode plays a central role in the efficiency and quality of the welding process.

Electron emission refers to the ability of the electrode material to release thermal electrons at high temperatures. This capability determines the ease of arc formation, arc stability, and the concentration of heat input.

Different electrode materials exhibit distinct differences in their electron emission capability under high-temperature conditions. This article will focus on lanthanum -tungsten electrodes, a rare earth-doped material, and analyze their advantages in electron emission under high-temperature welding conditions.

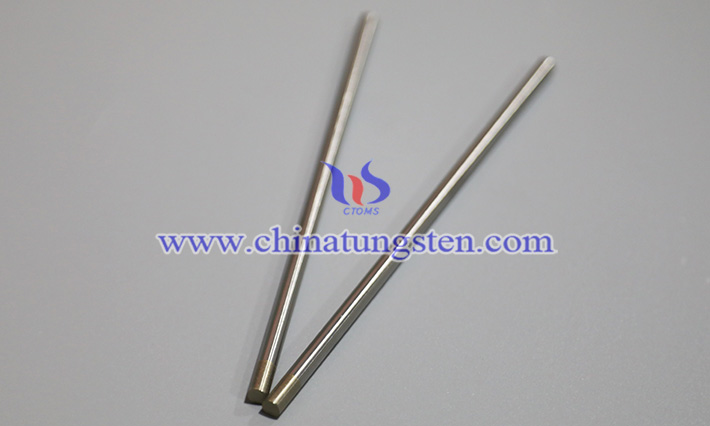

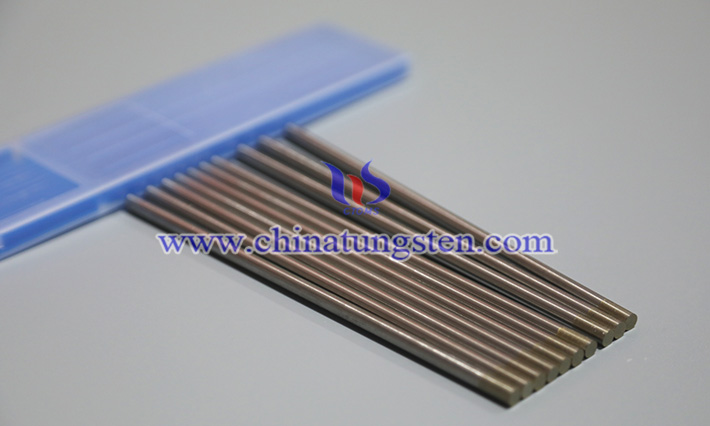

Lanthanum tungsten electrodes are made by adding a certain percentage of lanthanum oxide (La₂O₃) to pure tungsten, typically ranging from 1.0% to 2.0%. The introduction of this rare earth element changes the material's electronic structure, reducing tungsten's "work function" (the energy required to release electrons from the metal surface), making it easier for electrons to escape at high temperatures. This characteristic translates to easier arc starting, a more concentrated arc, and greater arc stability during extended welding.

While pure tungsten can withstand an extremely high melting point (approximately 3410°C) at high temperatures , its large electron work function makes it difficult to quickly form a stable arc during initial arc starting and under low current conditions. Lanthanum -doped materials, on the other hand, possess enhanced thermionic emission, enabling rapid electron flow and arc stability even at lower currents or shorter welding pulses. This offers significant advantages for automated welding equipment, precision welding systems, and thin-sheet welding.

In addition, the presence of lanthanum can also improve the material's ablation resistance to high temperature environments. Lanthanum oxide is dispersed in the tungsten matrix to form a fine-grained reinforcement structure that can effectively inhibit grain growth and tip erosion. This structural stability further enhances the electrode's ability to be used for a long time at high temperatures, keeping its tip in good shape, the electron emission surface uniform, and the arc without obvious drift or jitter.

In many experimental tests, the electron emission current density of lanthanum tungsten electrode under high temperature (such as 2000-2500℃) is significantly higher than that of pure tungsten, and can be maintained stably for a long time. This means that during continuous welding or high-load operation, it can not only maintain a good welding arc state, but also reduce the frequency of electrode consumption, thereby extending service life and improving welding efficiency.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com